Nowadays, charcoal making machine in Malaysia has become a good solution for waste management. This machine has the ability to turn waste biomass into high-quality charcoal. Malaysia has long been known for its rich natural resources. However, abundant resources also generate large amounts of biomass waste. They may come from agriculture, forestry, or food processing. In recent years, how to dispose of these wastes in an efficient and eco-friendly way has become a focus of attention in Malaysia. The emergence of Beston charcoal machine in Malaysia solves this problem. This machine not only helps solve the problem of wasting resources but also brings benefits to investors. With its advanced technology, the machine is favored by more and more Malaysian customers.

Charcoal Machine in Malaysia Plays an Important Role

Charcoal machine in Malaysia play a huge role. It not only optimizes resource management in Malaysia, but also creates considerable economic value. The following content will reveal to you the importance of the machine.

Waste Resource Management

Malaysia has a large amount of biomass waste, such as wood waste, crop residues, palm shells, etc. It is difficult to properly manage all these wastes. This machine can efficiently convert these wastes into valuable charcoal products. This enables full utilization of resources and reduces waste.

Environmental Protection

Biomass waste is usually piled up or burned, releasing harmful gases and pollutants. This disposal has a negative impact on the environment. By converting biomass waste into charcoal from a charcoal maker machine, air and soil pollution can be reduced. Moreover, greenhouse gas emissions can be lowered.

Economic Value Creation

The operation of the charcoal making machine in Malaysia can create employment opportunities. In addition, it also can promote economic development. Charcoal can be sold as a commodity, bringing income to charcoal enterprises. What’s more, the application of charcoal can also promote the development of related industries, such as barbecue catering, the energy industry, and the carbon credit market.

What Raw Materials Can Charcoal Making Machine in Malaysia Process?

Wood

This machine can process various types of wood such as sawdust, wood chips, branches, and logs. This resource is very common in Malaysia.

Crop Residues

Agricultural wastes can be used as raw materials for charcoal machines, including rice husks, straws, corn stalks, bagasse, coconut shells, and peanut shells, etc.

Palm Oil Wastes

Waste from palm oil processing, such as palm husks and empty fruit bunches (EFB), can be used as raw material for charcoal machines.

Other Biomass Wastes

The machine can also process other biomass wastes such as sludge and municipal solid waste. Disposal of these materials is to minimize the release of these wastes into the environment.

NOTE: The size and moisture content of the raw material used may affect the quality of the final charcoal product.

Significance of Charcoal in Malaysia – Applied in Various Fields

Charcoal can be widely used in Malaysia. In addition to its own economic value, it also makes an important contribution to the sustainable energy development of Malaysia. Below are some of the main application areas for charcoal.

Grilling and Cooking

Charcoal is a common grilling and cooking fuel in Malaysia and is widely used in outdoor barbecues, stoves, and charcoal cooking. It provides long-lasting high-temperature and unique flavor, making food more delicious.

Industrial Fuel

Charcoal is used as an industrial fuel, especially in metallurgy, ceramics, glass, and other heating and drying processes. It has high energy density and long-lasting combustion characteristics, suitable for industrial needs.

Shisha Charcoal

Charcoal can be used as hookah charcoal. Charcoal can provide moderate heat so that the temperature of the hookah can be controlled within a suitable range. In addition to this, charcoal can provide a long-lasting burn time.

Animal Feed Additive

Charcoal can be used as a feed additive in animal husbandry. Adding biochar to animal feed can help improve digestion and absorption. In addition, it can also improve feed utilization.

Soil Improvement

Adding biochar to soil can increase soil organic matter content, and improve soil water retention and permeability. In addition to that, biochar from biomass pyrolysis machine can absorb and hold nutrients. This helps improve crop growth.

Carbon Credit Market

Charcoal can be identified as a carbon load project in the field of agriculture and soil improvement. After these projects are certified, they can sell carbon credits in the carbon market.

Comparison Of Traditional Charcoal Kiln & Modern Carbonization Furnace

In Malaysia, there are two production methods to obtain charcoal. They are traditional charcoal kilns and modern carbonization furnaces. The following comparison will let you understand their differences better.

Production Method

The traditional processing method usually uses a closed earthen kiln structure. It produces charcoal by stacking raw materials in a kiln and closing the burner. The production process mainly relies on natural ventilation and the heat generated by the combustion process. In contrast, modern charcoal production uses mechanized and industrial methods. Charcoal is carried out by controlling temperature, oxygen supply, and reaction time.

Production Efficiency

Modern charcoal production equipment in Malaysia usually has higher carbonization efficiency. It enables better control of temperature, time, and pressure during the reaction process. This makes the reaction more uniform and efficient. In contrast, the efficiency of traditional charcoal kilns is low, the reaction time is long, and the temperature and degree of reaction may not be uniform enough.

Environmental Protection

Modern charcoal making process usually adopts advanced gas collection and purification systems. In this way, the machine can collect the bio-gas generated in the reactor to reduce environmental pollution. In comparison, traditional method usually produces more pollutants during the charcoal production process. This has a large negative impact on the environment.

Product Quality

Modern machines typically have higher throughput and more consistent product quality. It enables large-scale production and ensures the stability and consistency of the carbonization process through automated control. The output of traditional kilns is low, and the product quality may fluctuate.

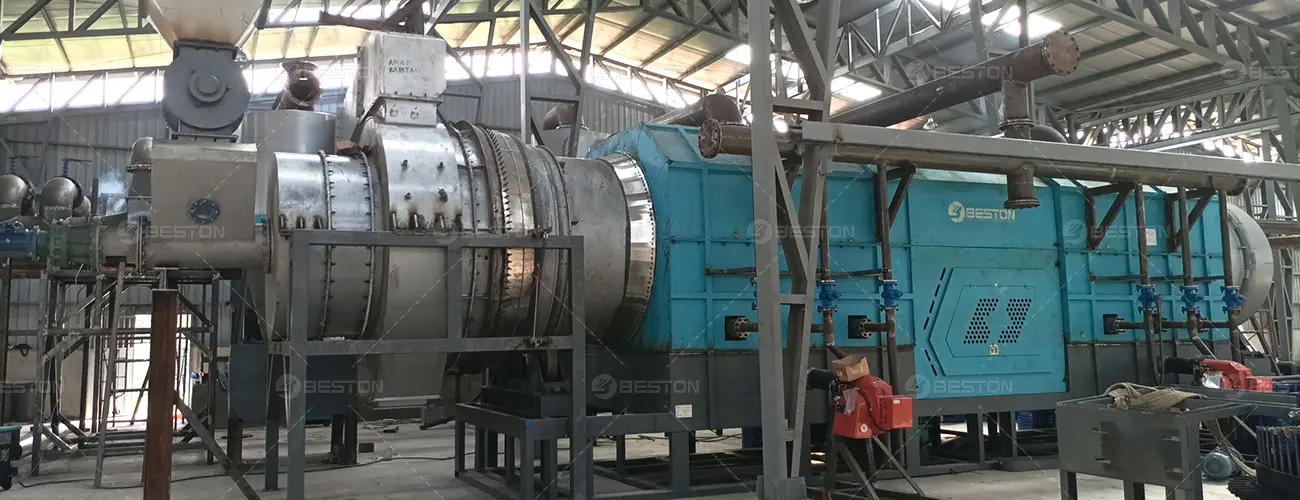

Models of Beston Charcoal Machine for Sale in Malaysia

Continuous biochar making machine is an advanced solution for large-scale charcoal production in Malaysia. It is characterized by high efficiency, continuous operation, and automation. The machine is designed to handle high volumes of biomass feedstock, which increases production and profitability. You can consult us at any time.

| Model | BST-50 Standard | BST-50S LM | BST-50S HM | BST-50S MAX | BST-06 Standard | BST-06MAX |

|---|---|---|---|---|---|---|

| Time to Market | 2015 | 2022 | 2022 | 2022 | 2025 | 2025 |

| Operating Mode | Continuous | Continuous | Continuous | Continuous | Continuous | Continuous |

| Application | Commercial Scale | Commercial Scale | Commercial Scale | Commercial Scale | Testing | Testing |

| Dust Removal System | Standard | Advanced | Advanced | Advanced | Standard | Advanced |

| Feeding Capacity | 10-15m³/h | 10-15m³/h | 10-15m³/h | 10-15m³/h | 100-300KG/H | 100-300KG/H |

| Biochar Discharge Temperature | 45℃ | 45℃ | 45℃ | 45℃ | 45℃ | 45℃ |

| Puro.earth Authentication Model | × | √ | √ | √ | × | |

| Maximum Pyrolysis temperature | 650℃ | 650℃ | 650℃ | 850℃ | 650℃ | |

| Service Life | 5-8 years | 5-8 years | 5-8 years | 8-10 years | 5-8 years | |

| Annual Operating Time | 7200 hours | 7200 hours | 7200 hours | 7200 hours | 8000 hours | |

| Land Space Required (L*W*H*m) | 35m×15m×8m | 65m×15m×8m | 65m×15m×8m | 65m×15m×8m | 25m*18m*6m | |

| Total Power (KW) | 201.25kW | 453.35kW | 505.35kW | 505.35kW | 129.79 | 162.79 |

| Cooling Method | Recycling cooling Water | Industrial chiller | Industrial chiller | Industrial chiller | Recycling cooling Water | Industrial chiller |

| Installation Period (Calendar Days) | 50 | 70 | 70 | 70 | 45 | 50 |

Video of the Charcoal Making Process

Successful Global Cases Of Beston’s Charcoal Making Machine

Established in 2013, Beston Group is an experienced manufacturer. We have extensive experience in producing and exporting charcoal machines. Over the years, we have actively established partnerships with various countries around the world. We have been committed to providing high-quality products and services to customers all over the world. The following are some successful cases for your reference.

Start Your Charcoal Making Business With Beston Group in Malaysia

In conclusion, charcoal making machine in Malaysia plays a vital role in sustainable resource utilization and renewable energy production. This machine provides a practical and eco-friendly solution for management of organic waste. Running charcoal making machine in Malaysia is a profitable business. If you want to set up your own charcoal production project, working with Beston Group can provide you with suitable equipment and professional technical support. Welcome to consult us on LinkedIn for solutions.