Worried about excessive wax oil during plastic pyrolysis? Concerned about the final oil quality? Facing safety risks from wax blockage during machine operation? Let Beston plastic pyrolysis plant boost your production efficiency by 200% with catalytic dewaxing technology! A single unit recycles 6000 tons of plastic waste annually. It’s not just about plastic recycling; it’s about maximizing investment returns by yielding high-quality, valuable oil products. Welcome to the inquiry.

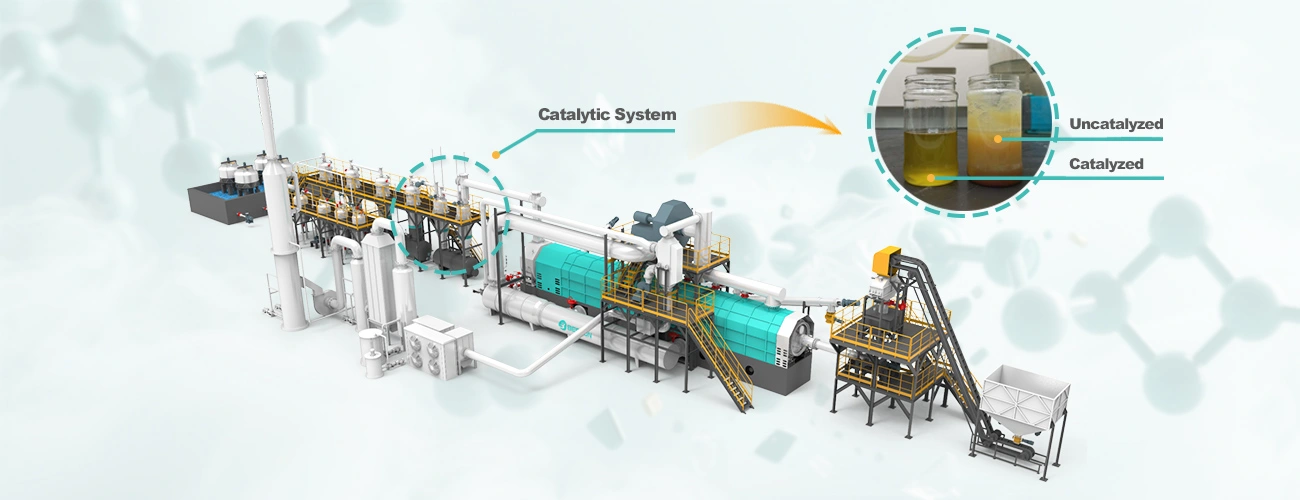

Catalytic Dewaxing Technology: Improve Production Efficiency by 200%

Catalytic System: Function Mechanism & Benefits

Catalytic dewaxing targets the “undesirable” molecules in pyrolysis oil distillates, that is, those with poor cold flow properties (the wax oil). Under the action of a specialized catalyst, the long-chain wax molecules are cracked into shorter-chain hydrocarbons, such as alkanes and alkenes. This modifies the molecular structure and properties of the wax. This helps to get the best pyrolysis oil performance. Finally, it brings such advantages:

- Better oil quality and higher yield: Able to produce plastic pyrolysis oil meeting ISCC certification.

- Safer pyrolysis reaction: Minimize the pressure risk of plastic pyrolysis machine by reducing wax oil blocking.

- Less downtime, fewer losses: Keeps your machine running smoothly, with improved equipment lifespan and maintenance intervals.

Specifications of Plastic Pyrolysis Plant for Sale

Continuous Type: BLL-30

- Process 6,000 tons waste plastic annually

- 30 day continuous operation

- High automation: two operators required

- Policy support and incentives

- Easy to get environmental compliance and approval

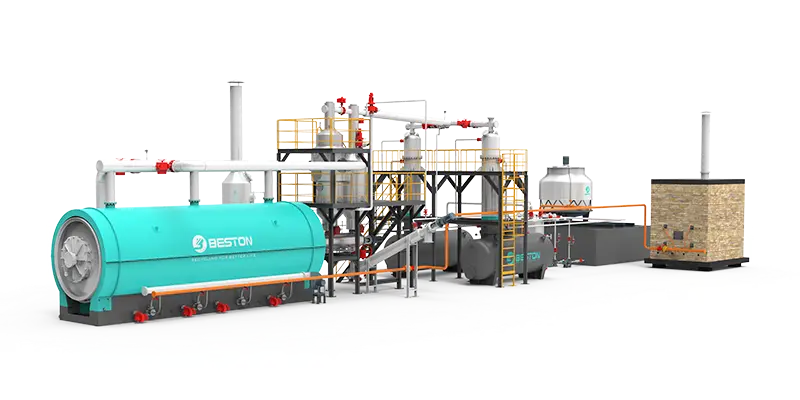

Batch Type: BLJ-20

- Process 4,000 tons waste plastic annually

- Get naphtha & non-standard diesel in one step

- 1 batch/day

Batch Type: BLJ-16

- Process 3,000 tons waste plastic annually

- 1 batch/day

- 4 Configuration options

| Model | BLL-30 | BLJ-20 | BLJ-16 WAX | BLJ-16 CAT | BLJ-16 Standard | BLJ-16 ULTRA |

|---|---|---|---|---|---|---|

| Manufacturer | BESTON | BESTON | BESTON | BESTON | BESTON | BESTON |

| Time to Market | 2025 | 2025 | 2022 | 2022 | 2013 | 2022 |

| Motor Brand | Chinese brand | Chinese brand | Chinese brand | Chinese brand | Chinese brand | ABB Explosion-proof |

| Suitable Raw Materials | Waste plastics; Tires; Oil sludge | Waste plastics; Tires; Oil sludge | Waste plastic bales (Max.0.9*0.9*1.6m) | Waste plastic bales (Max.0.9*0.9*1.6m) | Whole tire<120cm; Tire blocks<15cm; Oil soil with liquid content<30% | Waste plastics; Tires; Oil sludge |

| Input Capacity (Max.) | Waste plastic pellets: 0.8-1.05t/h Rubber powder: 1.25-1.5t/h Oil sludge:1.8-2.3t/h | Waste plastic pellets: 12-13t/d Tire: 18-20t/d Oil sludge:20-25t/d | 8-10t/batch | 8-10t/batch | Whole tire <120cm or Tire blocks<15cm: 10-12t/batch Sidewall removed tire: 15-16t/batch Oil soil: 16-18t/batch | Waste plastic bales: 8-10t/batch Whole tire <120cm or Tire blocks<15cm: 10-12t/batch Sidewall removed tire: 15-16t/batch Oil sludge: 16-18t/batch |

| Working Method | Fully Continuous | Batch | Batch | Batch | Batch | Batch |

| Final Oil Quality | Pyrolysis oil Pyrolysis oil with wax or naphtha | Pyrolysis oil, Non-standard diesel and naphtha | Pyrolysis oil with wax | Pyrolysis oil with naphtha | Pyrolysis oil | Pyrolysis oil Pyrolysis oil with wax or naphtha |

| Reactor Material | 304/310S Stainless steel | Q345R Boiler steel and 304/316L/310S Stainless steel | 304 Stainless steel | 304 Stainless steel | Q345R Boiler steel | 304 Stainless steel |

| Reactor Life Span (Years) | 5-8 | Q345R Boiler steel 2-3 304/316L Stainless steel 5-8 310S Stainless steel 8-10 | 5-8 | 5-8 | 2-3 | 5-8 |

| Guarantee (Months) | 12 | 12 | 12 | 12 | 12 | 12 |

| Delivery Time (Calendar Days) | 60-90 | 60 | 60 | 60 | 45 | 90 |

| Land Space Required (L*W*H*m) | 70*20*10 | 40*13*8 | 33*13*8 | 33*13*8 | 33*13*8 | 33*26*8 |

| Packing | 20*6*3m in bulk+13*40HQ | 1*40FR+4*40HQ | 1*40FR+3*40HQ | 1*40FR+3*40HQ+1*20GP | 1*40FR+3*40HQ | 1*40FR+8*40HQ |

| Installation Period (Calendar Days) | 60-90 | 45 | 45 | 45 | 45 | 60 |

BLJ-20 Plastic Pyrolysis Machine: Double Your Oil Revenue

One Step Get Naphtha & Non-Standard Diesel

Fraction Distillation Technology of BLJ-20 pyrolysis-distillation interated pyrolysis plant separates oil fractions at a 200°C cut point during pyrolysis.

- Below 200°C: Naphtha → directed to the light oil tank

- Above 200°C: Non-standard diesel → directed to the heavy oil tank

Key Benefits:

- No need for extra distillation equipment, lowering occupied space and capital expenditure.

- Higher yield through reflux & heat integration

- Lower overall energy consumption & shorter production cycle

50% ↑ in Processing Capacity

Large-capacity plastic pyrolysis reactor (ø2800*10000) increases the daily capacity from 8-10 ton/day to 12-13 ton/day, improving 50% to before.

Efficiency Advantages:

- Higher output per unit time

- Reduced footprint & duplicate construction costs

- Expand production scale, driving overall profitability

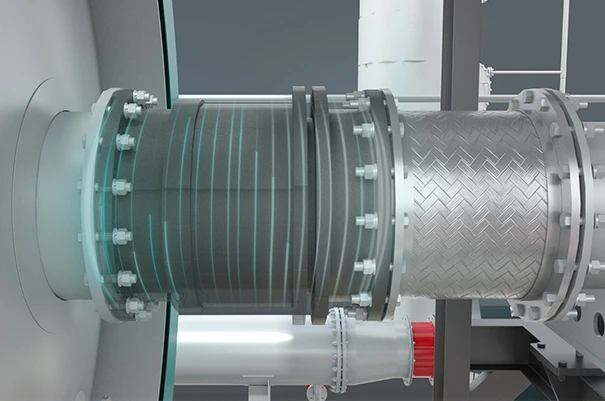

High Safety Factor

Thermal Dynamic Sealing & Flexible High-temperature Insulation Technology significantly enhances sealing and insulation performance.

Safety & Reliability Advantages:

- No open flames and oil-gas release, greatly improving operational safety;

- Reduce high-temperature impact, creating a safer working environment;

- Extend equipment lifespan, lower maintenance frequency, and minimize downtime costs.

BLL-30 Plastic Pyrolysis Plant: Scaled-Up Industrial Solution

30 Day Continuous Operation

Oil-Gas Anti-Polymerization Condensation Technology utilizes spray condensation to lower oil-gas temperature rapidly. This prevents olefin polymerization that can clog oil-gas pipelines and machine. The technology minimizes shutdowns and maintenance of the BLL-30 continuous pyrolysis plant. Finally, it benefits your plastic pyrolysis investment:

- Handle 6,000 tons of plastic waste annually.

- Output stable and large-amount plastic pyrolysis oil.

- Achieve faster ROI

Annual Profit Reference: PE plastic | 6,000 tons/year | 90% oil yield | $550/ton → $2,970,000/year

↓55% Fuel Use · ↓50% Emissions

Hot Flue Gas Recycling + Combustion Air Preheating Technology is as follows:

- Hot Flue Gas Recycling: Guide 80% of hot flue gas from reactor back into combustion chamber. Mix it with 1000-1300℃ hot air from combustor. Use the mixture to heat the reactor.

- Combustion Air Preheating: Use the remaining 20% hot flue gas to heat fresh combustion air. Thus, the hot combustion air can offer the necessary oxygen condition to combustor.

This highlight will benefit your investment:

- Less Fuel Cost: 100% waste heat reuse lowers external fuel consumption.

- Easier Emission Compliance & Less Investment: 50% fewer emissions lower the complexity and capital cost of gas treatment systems.

±10℃ Precise Temperature Control

Reactor Automatic Temperature Control Technology adopts multi-fuel automatic combustion system + hot-air reuse system for the reactor. It achieves automatic adjustment for fuel mix ratio based on fuel properties. Thus, it achieves precise ±10°C temperature control. How does it benefit your investment?

- More stable plastic pyrolysis oil quality and yield

- Less manual operation, lower 80% labor costs

- More efficient combustion, better emission control, and easier environmental compliance

Get 3 Distinct Oil Products from Plastic Pyrolysis Plant to Apply

Plastic pyrolysis is the mechanism of thermally degrading long-chain plastic molecules into smaller molecules (oil, gas and char) using heat in an oxygen-free environment. Its process conditions and additional refining techniques determine the type of oil product obtained. Here’s how distinct oil products can be derived:

Naphtha / Naphtha from Non-condensable Gas

Source: pyrolysis+ distillation

Property: A low-boiling-point fraction, a light hydrocarbon product separated from pyrolysis oil.

Applications:

- produce basic chemicals (e.g., ethylene, propylene → plastics, synthetic fibers);

- used in paints, coatings, cleaners, and industrial solvents;

- used to blend gasoline for better performance;

- used to produce kerosene, jet fuel, and other fuels;

- used as an extraction solvent and cleaning agent in labs.

Non-Standard Diesel

Source: pyrolysis+ distillation

Property: A middle distillate hydrocarbon fraction from pyrolysis oil, heavier than naphtha.

Applications:

- as a kind of industrial fuel to replace traditional fuel oil;

- used as fuel for diesel generators for power generation;

- serve as fuel in ships, construction, or agricultural machinery where emission standards are less strict.

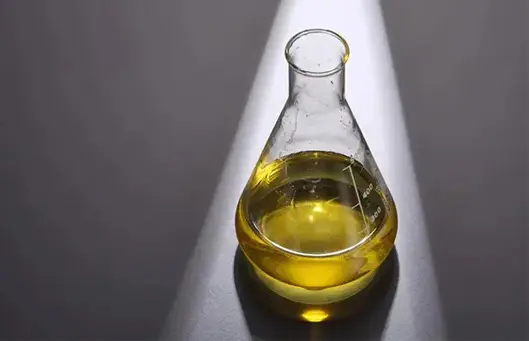

Catalytic Pyrolysis Oil

Source: catalytic pyrolysis

Property: A purer oil with fewer impurities than the common uncatalyzed waxy pyrolysis oil.

Applications:

- fuel for energy-intensive industries such as boiler plants, cement factories, and brick-making plants;

- serve as a kind of chemical feedstock for producing petrochemicals and intermediates (e.g., used to produce ethylene monomers for new plastics).

Are All Plastic Suitable for Plastic Pyrolysis Equipment?

Acceptable Plastic Types

| Types of Plastic | Coming from | |

|---|---|---|

|

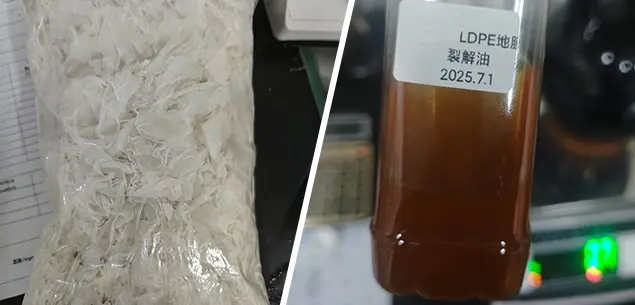

Low-Density Polyethylene | Cling films, freshness protection bags, etc. |

|

High-Density Polyethylene | Plastic pallets, trash cans, etc. |

|

Polypropylene | Microwave lunch box, fresh-keeping box, etc. |

|

Polystyrene | Fast food box, bowl of instant noodles, etc. |

|

Other Plastics without chlorine and oxygen | Various sources |

Note: PP, PE, and PS plastics are highly recommended for pyrolysis due to their high oil yield of 80%-95%. They offer great economic recovery value.

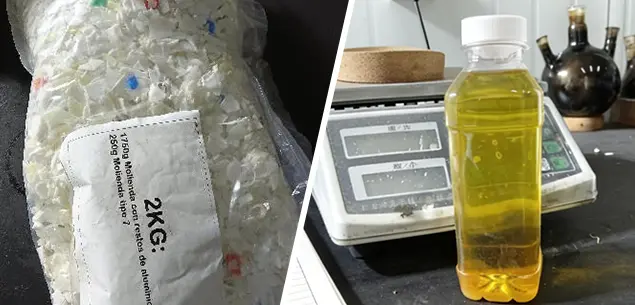

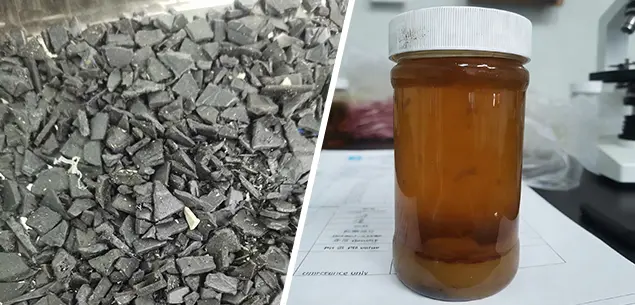

Pyrolysis to Oil Test Reports

Between 2024 and 2025, different plastic samples were sent to Beston Group’s manufacturing base in Jiaozuo, China, for testing. Explore more pyrolysis to oil test reports.

Unacceptable Plastic Types

| Types of Plastic | Coming from | |

|---|---|---|

|

Polyethylene Terephthalate | Mineral water bottles, carbonated beverage bottles, etc. |

|

Polyvinyl Chloride | Raincoat, building materials, etc. |

|

Other plastics with chlorine and oxygen | Various sources |

Note: Plastics containing high amounts of oxygen(O) and chlorine(Cl) are not suitable for pyrolysis. These two substances pose risks to machine, air quality, and worker safety.

Polyvinyl Chloride (PVC)

- Contains chlorine, which releases harmful HCl gas during plastic pyrolysis process. HCl gas corrodes equipment, harms the environment, and poses health risks to workers.

- Even if PVC pyrolysis yields oil, the oil still contains chlorine (Cl). When burned, it can release dioxins—highly toxic and carcinogenic compounds.

Polyethylene Terephthalate (PET)

- PET yields little to no oil through pyrolysis. The resulting products are mostly low-quality, powdery residues with little economic value.

- PET(chemical formula (C₁₀H₈O₄)ₙ) releases oxygen in pyrolysis. The oxygen reacts with combustible pyrolysis gas, leading to explosive risks.

Benchmark Cases on Plastic Pyrolysis Project

Benchmark Case 1: Plastic Pyrolysis Project in Finland

Benchmark Case 1: Plastic Pyrolysis Project in Finland

Corsair Group is one of the rapidly growing companies in the field of plastic waste chemical recycling. To combat the global plastic challenge, they are committed to developing large-scale, efficient, and feasible plastic recycling solutions. To achieve this, Corsair is investing resources to develop advanced pyrolysis recycling technologies, aiming to secure an early strategic position in the market.

Project Information

- Customer: Corsair Group

- Location: Jämsä, Finland

- Project Duration: 8 May 2024 – 29 October 2025 (~17 months)

- Project Configuration: 3 × BLJ-16 plastic pyrolysis units

- Annual Processing Capacity: 4,000 tons/unit (total 12,000 tons)

- Plastic Pyrolysis Oil Use: Sold as fuel

Project Status

- Installation & Commissioning: Our engineering team installed and tested 3 BLJ-16 units on-site. Each unit was tested for stable operation.

- Daily Operation: The pyrolysis units operate at 280 – 350°C, achieving consistent oil output. Operators reported smooth startup procedures and predictable throughput.

- Phase I Completed: 3 units fully operational. Phase II will expand capacity with additional units, strengthening strategic cooperation between Beston and Corsair.

Benchmark Case 2: Plastic Pyrolysis Plant in Western Europe

Benchmark Case 2: Plastic Pyrolysis Plant in Western Europe

01 Background & Challenges

In line with the EU’s circular plastics strategy, a European startup plans to build a plastic chemical recycling plant (plastic to oil machine). The core objective is to produce new plastics without consuming additional natural resources and reducing CO₂ emissions from the plastics industry. Requirements:

- Dispose of a large amount of plastic waste.

- The plant must meet nitrogen oxide emission standards.

- The problem of wax oil in plastic pyrolysis needs to be solved.

02 Solution

- Design multiple plastic pyrolysis equipment operating side by side, achieving 30TPD daily processing capacity.

- According to local emission reports, upgrade combustion system and configure a high-end exhaust gas treatment system.

- Adopt catalytic dewaxing technology to prevent wax oil clogging pipelines, improving production efficiency by 200%.

03 Value Added

- Through the customer’s plastic waste processing center, it effectively meets the growing demand for plastic waste recycling and reduces CO2 emissions.

- Sell pyrolysis oil to partners to produce new plastics, thereby perfectly realizing a closed loop.

ISCC PLUS Certification for Plastic Pyrolysis Oil

– Beston Group Ensures Technical Compliance

01 What Is ISCC PLUS?

ISCC (International Sustainability & Carbon Certification) is a globally leading certification system aimed at enhancing traceability, sustainability, deforestation-free, and climate-friendly supply chains. ISCC PLUS is a subset of the ISCC system. ISCC PLUS is a voluntary certification scheme designed to validate sustainability characteristics of alternative feedstocks.

02 Benefits for ISCC PLUS Certification

- Confirm that products meets global sustainability standards.

- Increase competitiveness and enables entry into higher-end markets.

- Enhance brand reputation via showcasing your commitment to sustainability.

03 How Beston Group Helps with ISCC PLUS Application

Beston Group supports plastic pyrolysis oil manufacturers in obtaining ISCC PLUS certification by ensuring technical compliance at every stage:

- Technical Compliance Assurance: The plastic pyrolysis plant design and production processes follow strict technical and environmental standards.

- Documentation & Data Support: Key operational data are fully traceable. We assist in submitting technical data required for ISCC PLUS audits.

04 ISCC PLUS Pyrolysis Oil Project Case Study

In the above Benchmark Case 1 Finland plastic pyrolysis project, the pyrolysis oil successfully obtained ISCC PLUS certification. This involved the key stages:

- Equipment Deployment & Oil Production: 3 batch pyrolysis units were smoothly set up, with stable operations producing high-quality plastic pyrolysis oil.

- ISCC PLUS Certification Application: Following oil production, the ISCC PLUS certification application was initiated, with full data support to ensure compliance.

- Oil Application: The ISCC-certified oil from this project will be supplied to the chemical industry, which supports circular economy and carbon reduction goals.

- Note 1: Pyrolysis oil manufacturers remain responsible for feedstock and other compliance aspects.

- Note 2: Certification should be applied for by the plastic pyrolysis oil manufacturer. Beston Group acts as technical and documentation/data support provider, not as the certification body.

From Plastic to Pyrolysis Oil: Macromolecules vs Micromolecules

Plastics: Macromolecules

Plastics are composed of long-chain macromolecules (polymers) formed by the polymerization of numerous small molecules (monomers). For example:

Polyethylene (PE): During polymerization, the double bond in ethylene monomers (C₂H₄) breaks open, and links with the double bonds of other ethylene monomers to form long chains (-CH₂-CH₂-). PE is represented as: [-CH₂-CH₂-]ₙ, where ‘n’ indicates repetition multiple times. PE often consists of thousands to millions of ethylene units.

Plastic Pyrolysis Oil: Small Molecules

Pyrolysis oil mainly consists of smaller hydrocarbon compounds, typically alkanes, alkenes, and minor aromatic compounds. For example:

PE pyrolysis: The long polymer chains break apart into shorter carbon chains, producing molecules such as:

- Alkanes (Ethane C₂H₆, Propane C₃H₈, Butane C₄H₁₀, etc.).

- Alkenes (Ethylene C₂H₄, Propylene C₃H₆, Butylene C₄H₈, etc.).

Free Radical Reactions in Plastic Pyrolysis Process

Taking polyethylene (PE) as an example, its decomposition from macromolecules to micromolecules proceeds through the following steps:

- Chain Scission Generates Free Radicals: The long polyethylene chain (–CH₂–CH₂–CH₂–CH₂–CH₂–….) first breaks during pyrolysis to generate CH₂• free radicals. Example: CH₂-CH₂ → CH₂• + •CH₂

- Free Radical Recombination: These free radicals are highly active at high temperatures and can undergo recombination reactions. For example, two CH₂• free radicals might combine to form an ethylene (C₂H₄) molecule: CH₂• + •CH₂ → C₂H₄

- Formation of Propylene: Sometimes, the CH₂• free radical might react with the cracked monomers or smaller molecules. For example, two ethylene (C₂H₄) molecules might react to form propylene (C₃H₆): C₂H₄ + CH₂• → C₃H₆

Through successive scission and recombination, the final pyrolysis oil which consists of different small molecules (C₂H₄, C₃H₆, etc.) is formed.

How Plastic Pyrolysis Plant Work? – Plastic to Oil Conversion

01 Pretreatment and Feeding

Raw materials need to be processed into different sizes for feeding. Different feeding sizes for your reference:

- BLL-30: Work in continuous mode. Feed size diameter is less than 20mm. Feed plastic by screw feeder.

- BLJ-16: Work in batch mode. Feed size diameter is less than 1200mm. Feed plastic by manual labor.

02 Plastic Catalysis Pyrolysis

Heat the plastic pyrolysis reactor. When the temperature reaches 180 degrees Celsius, gas oil begins to generate. A significant amount of gas oil appears at temperatures between 280-350 degrees Celsius.

After the oil gas enter the catalytic tower, it reacts with the catalyst. This step mitigates issues related to wax deposition and liquefaction. Simultaneously, it contributes to enhancing the quality of the plastic pyrolysis oil.

03 Plastic Pyrolysis Oil Collection

The oil gas enters the manifold, and heavy particles of the oil gas will be liquefied and dropped into the heavy oil tank. The light oil gas will be liquefied into fuel oil by the condenser and stored in the fuel oil tank.

04 Combustible Gas and Solid Residues Recycling

The non-liquefiable oil gas will be desulfurated and cleaned in the hydro seal. Then it is recycled to the burning room to provide heat energy for plastic pyrolysis equipment.

The water-cooling discharger will discharge the solid residues.

05 Emission Gas Recycling

Advanced Designs of Beston Plastic Pyrolysis Plant

Dual System Technology

Manifold + catalytic tower dual system supports flexible operation modes. It enables the catalytic pyrolysis of waxy plastics or waxy oil sludge. It also allows common pyrolysis for common tires or oil sludge.

- Save customers from redundant investments.

- Improve the utilization efficiency of plastic pyrolysis machine, and enhance economic returns.

Continuous Pyrolysis Technology

BLL-30 model integrates many advanced technologies to enable continuous pyrolysis, unique compared to peer machines. Advanced designs include:

- Sealed feeding system with continuous quantitative control, Real-time monitoring and stage statistics;

- Inert gas (nitrogen) protection system;

- Accurate temperature control for high-temperature flue gas reuse;

- Others.

Safety

- Installation safety: The plastic pyrolysis reactor uses high-temperature ceramic wool of the British Morgan brand. This ensures no carcinogens or risk of lung infection for workers. It complies with EU standards.

- Operation safety: It has explosion-proof motor, torch system, electric control cabinet, automatic alarm, etc.

- Environment safety: Water-cooling discharging scheme reduces dust pollution. Dedusting system prevents air pollution.

Intelligentization

- PLC and DCS remote control system: It features a high level of automation. This enhances production efficiency and reduces the needs and risks of manual operation.

- IoT technology: It enables real-time online monitoring and feedback. This makes the production process of plastic pyrolysis plant more intelligent and automated.

Certifications, Patents, and Industry Recognition in Pyrolysis

ISO & CE Authoritative Certification

Industry Recognition & Pyrolysis Patents

ISO 9001 QMS Certificate

Ensures standardized quality across R&D, production, and after-sales, guaranteeing stable and reliable equipment performance.

ISO 14001 EMS Certificate

Confirms compliance with international environmental management standards, supporting sustainable production and environmentally responsible operations.

CE European Certification

Complies with European safety, health, and environmental standards, ensuring product safety and regulatory compliance in international markets.

Industry Standards Participation

Participated in the drafting of the “China Solid Waste Pyrolysis Treatment Standard,” reflecting recognized industry influence.

2 European Patents

Awarded by European Intellectual Property Office for continuous pyrolysis plant design, demonstrating internationally recognized technological innovation.

44 Chinese Patents

Awarded by the China National Intellectual Property Administration for multiple pyrolysis equipment designs, demonstrating long-term commitment to technological innovation.

Plastic Pollution Is Everywhere: This Is Why Recycling Is Essential

Plastic Pollution in Soil

Plastic Pollution in Ocean

Plastic Pollution in Atmosphere

Plastic Pollution in Human Body

Plastic Pollution in Soil

A study shows that contaminated soils accumulate substantial amounts of plastics worldwide. It is with a mean of 6153 particles per kilogram of soil. This pollution in the soil is commonly caused by mulch film, agricultural packaging, polymer-containing fertilizers, and so on.

- limit the soil’s capacity to hold water, discourage plants’ root growth and nutrient uptake, and decrease agricultural yields.

- take hundreds or even thousands of years to decompose completely, causing long-term effects on soil ecological functions.

Plastic Pollution in Ocean

Nowadays, more than 10 million tons of plastic waste end up in the ocean each year. And the rate of ocean plastic pollution is rapidly increasing. Common sources of plastic pollution include fishing gear, urban garbage, etc.

- pose severe impacts on the predation and survival of marine wildlife, leading to some species being on the brink of extinction.

- pose risks to the water and animals in the marine ecosystem due to the additives and harmful chemicals in plastic.

Plastic Pollution in Atmosphere

The main sources of plastic pollution in the atmosphere are plastic production, plastic burning, and microplastics. Plastic production, use, and management all contribute to atmospheric pollution.

- cause climate change (Producing 1 ton of plastic generates about 20% of CO2 and other greenhouse gases.).

- affect the health of animals, plants, and humans when burning plastic releases toxins (HCl and CO) into the air.

Plastic Pollution in Human Body

One study shows that a person eats 5g of microplastics per week on average (about the same as eating a credit card’s worth of plastic). The sources include bottled water, food, air, and so on.

- enter the human bloodstream through inhalation or ingestion and have an impact on human cells.

- affect certain bodily functions because of the harmful chemical additives present in plastics.

Feasibility Analysis of Plastic Recycling

Market capacity and trend

Current recycling situation

Statistics from the Organisation for Economic Co-operation and Development show only about 9% of plastic waste is currently recycled, 10%-20% is incinerated, 30% is improperly disposed of, and nearly 50% is landfilled. So the world still needs effective plastic recycling solution.

Environment challenge

Plastic waste poses significant environmental hazards, polluting various ecosystems. Additionally, the production and degradation of plastics release greenhouse gases, exacerbating climate change. So, plastic recycling is extremely urgent. Waste plastic pyrolysis plant is a good solution.

Policy promoting

The USA, EU, Australia, China, Thailand, Malaysia, etc., have enacted laws and regulations requiring plastic waste recycling. For example, the EU’s PPWR proposal mandates that by 2030, at least 30% of recyclable content must be included in all plastic packaging in the EU market.

Benefits of Plastic Pyrolysis: Sustainable Recycling Starts Here

Plastic Reduction

Plastic Reduction

Plastic pyrolysis equipment can effectively reduce the quantities and existence time of plastic waste in the environment. Thus, it can lower the risk of environmental pollution from plastic accumulation or landfills.

Plastic Resource Sustainability

Plastic Resource Sustainability

Plastic to fuel machine transforms plastic waste into pyrolysis oil that can be used as an alternative energy. This avoids the non-treatment or improper disposal of waste plastics and realizes the sustainable use of plastic resources.

Towards to Circle Economy

Towards to Circle Economy

Globally, approximately 10% of petroleum is used for plastic production. Plastic pyrolysis oil can be recycled into new plastic products. This recycling reduces the need for virgin fossil oil. It supports the development of a circular economy where resources are continually reused and conserved.

Technical Documents Of Plastic Pyrolysis Plant – Beston Group Offers

EPC Service: Realize Your Plastic Pyrolysis Project

01 Concept

EPC stands for Engineering, Procurement, and Construction, offering an integrated solution for your plastic pyrolysis project. We provide full-process services from project planning to operational startup, making project implementation more efficient and convenient.

02 Value

With EPC service, clients avoid the hassle of coordinating multiple suppliers and managing separate stages, saving time, effort, and reducing project risks. We take care of the entire process, ensuring a stable and efficient pyrolysis production line.

03 Scope of Services

- Industrial park planning and design

- Steel structure workshop construction

- Equipment Installation and commissioning

- Park roads, water supply and drainage works

- Supporting facilities such as office buildings and dormitories

Let Plastic Pyrolysis Contribute to 2030 Plastic Goal

In recent years, the global community has rallied around an ambitious yet essential mission — to reduce plastic pollution and promote sustainable materials management.The 2030 plastic goals represent a series of international commitments aiming to:

- Eliminate unnecessary plastic packaging

- Ensure all plastic packaging is reusable, recyclable, or compostable

- Increase the rate of plastic waste recycling

- Drastically reduce plastic leakage into the environment

Global efforts such as the UN Global Plastic Treaty and national plastic strategies are driving the push toward the sustainable plastic management goal. Some industry leaders (e.g., Shell, TotalEnergies, and Nestlé) are investing in advanced plastic recycling facilities (including waste plastic pyrolysis machine) to promote.

The path to meeting the 2030 plastic goal is challenging—but not impossible. By embracing plastic pyrolysis, we can reduce plastic pollution, preserve natural ecosystems, and build a truly circular plastic economy. Let’s empower pyrolysis to drive sustainability and take a big step closer to a cleaner, greener 2030.

Launch Your Plastic Pyrolysis Project!

Plastic pyrolysis plants play a crucial role in extending the lifespan of plastics and combating plastic pollution. This approach presents new opportunities for the sustainable development of the plastic industry. Let’s join the plastic recycling together and contribute to a more sustainable and environmentally responsible future. Follow LinkedIn channels for the latest updates about plastic pyrolysis!