Plastic into fuel machine offers an alternative solution to waste recycling and fossil fuel usage. Through catalytic pyrolysis technology, the machine converts waste plastic into ISCC grade fuel oil without clogging shutdown. Thus, this innovative machine can provides 200% efficiency improvement. For recyclers, plastic to fuel machine not only promotes sustainable plastic recycling, but also relieves current pressure on fossil fuel supplies. Read further to uncover the full potential of this waste-to-value innovation.

Fueling Efficiency: Catalytic Pyrolysis Technology for Plastic into Fuel Machine

Traditional plastic pyrolysis plant often faces problems such as wax oil accumulation and pipeline blockage. Catalytic pyrolysis, by introducing specific catalysts, promotes the conversion of wax oil during the pyrolysis process, turning it into a light oil product that is not easy to solidify. This system creates the following value for the equipment:

ISCC Certified Oil Production

Catalytic pyrolysis efficiently converts wax oil into pyrolysis oil that meets ISCC (International Sustainable Carbon Certification) standards. This ensures the sustainability of oil products. Customers can use the certificate to enhance brand reputation and meet the stringent requirements of international buyers for sustainable raw materials.

200% Efficiency Increase

Catalytic liquefaction technology effectively decomposes wax oil components. This completely eliminates pipeline blockage and equipment downtime. As a result, the production efficiency of plastic to fuel machine is increased by about 200%. The daily processing volume is greatly increased while reducing maintenance costs.

3 Model Plastic to Fuel Machine for Sale

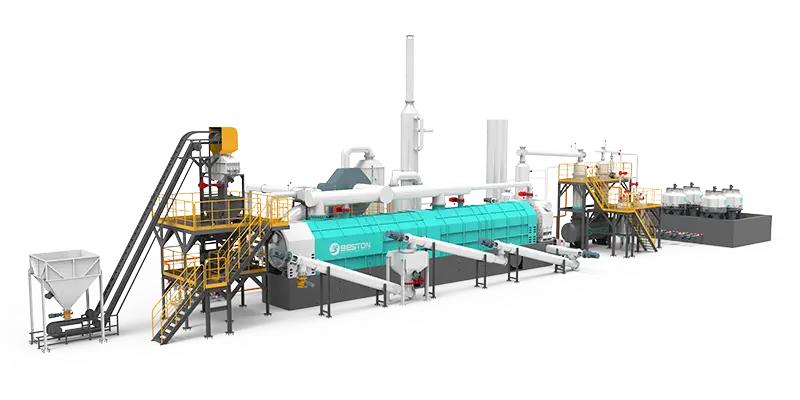

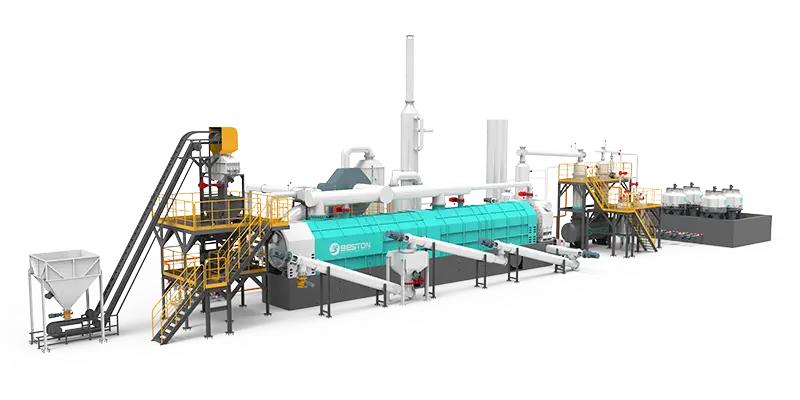

Continuous Type: BLL-30

- Process 6,000 tons waste plastic annually

- 30 day continuous operation

- High automation: two operators required

- Policy support and incentives

- Easy to get environmental compliance and approval

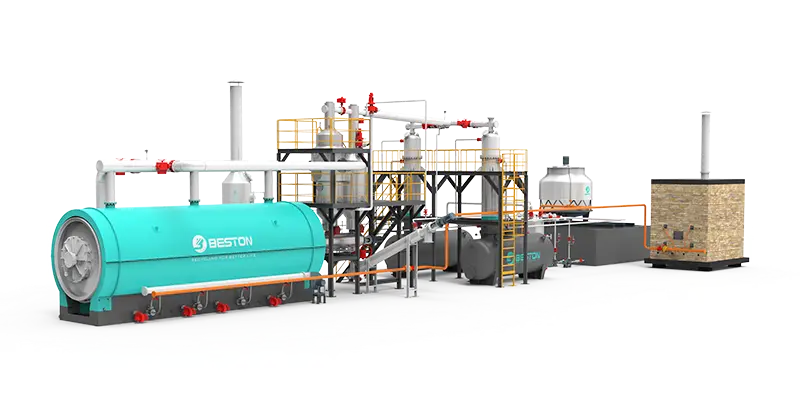

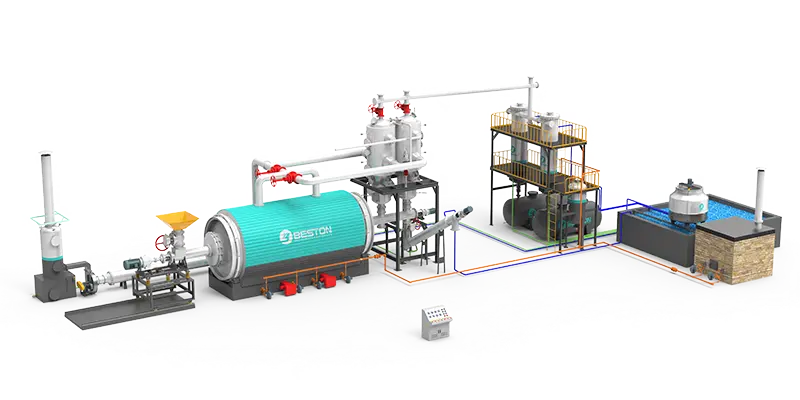

Batch Type: BLJ-20

- Process 4,000 tons waste plastic annually

- Get naphtha & non-standard diesel in one step

- 1 batch/day

Batch Type: BLJ-16

- Process 3,000 tons waste plastic annually

- 1 batch/day

- 4 Configuration options

| Model | BLL-30 | BLJ-20 | BLJ-16 WAX | BLJ-16 CAT | BLJ-16 Standard | BLJ-16 ULTRA |

|---|---|---|---|---|---|---|

| Manufacturer | BESTON | BESTON | BESTON | BESTON | BESTON | BESTON |

| Time to Market | 2025 | 2025 | 2022 | 2022 | 2013 | 2022 |

| Motor Brand | Chinese brand | Chinese brand | Chinese brand | Chinese brand | Chinese brand | ABB Explosion-proof |

| Suitable Raw Materials | Waste plastics; Tires; Oil sludge | Waste plastics; Tires; Oil sludge | Waste plastic bales (Max.0.9*0.9*1.6m) | Waste plastic bales (Max.0.9*0.9*1.6m) | Whole tire<120cm; Tire blocks<15cm; Oil soil with liquid content<30% | Waste plastics; Tires; Oil sludge |

| Input Capacity (Max.) | Waste plastic pellets: 0.8-1.05t/h Rubber powder: 1.25-1.5t/h Oil sludge:1.8-2.3t/h | Waste plastic pellets: 12-13t/d Tire: 18-20t/d Oil sludge:20-25t/d | 8-10t/batch | 8-10t/batch | Whole tire <120cm or Tire blocks<15cm: 10-12t/batch Sidewall removed tire: 15-16t/batch Oil soil: 16-18t/batch | Waste plastic bales: 8-10t/batch Whole tire <120cm or Tire blocks<15cm: 10-12t/batch Sidewall removed tire: 15-16t/batch Oil sludge: 16-18t/batch |

| Working Method | Fully Continuous | Batch | Batch | Batch | Batch | Batch |

| Final Oil Quality | Pyrolysis oil Pyrolysis oil with wax or naphtha | Pyrolysis oil, Non-standard diesel and naphtha | Pyrolysis oil with wax | Pyrolysis oil with naphtha | Pyrolysis oil | Pyrolysis oil Pyrolysis oil with wax or naphtha |

| Reactor Material | 304/310S Stainless steel | Q345R Boiler steel and 304/316L/310S Stainless steel | 304 Stainless steel | 304 Stainless steel | Q345R Boiler steel | 304 Stainless steel |

| Reactor Life Span (Years) | 5-8 | Q345R Boiler steel 2-3 304/316L Stainless steel 5-8 310S Stainless steel 8-10 | 5-8 | 5-8 | 2-3 | 5-8 |

| Guarantee (Months) | 12 | 12 | 12 | 12 | 12 | 12 |

| Delivery Time (Calendar Days) | 60-90 | 60 | 60 | 60 | 45 | 90 |

| Land Space Required (L*W*H*m) | 70*20*10 | 40*13*8 | 33*13*8 | 33*13*8 | 33*13*8 | 33*26*8 |

| Packing | 20*6*3m in bulk+13*40HQ | 1*40FR+4*40HQ | 1*40FR+3*40HQ | 1*40FR+3*40HQ+1*20GP | 1*40FR+3*40HQ | 1*40FR+8*40HQ |

| Installation Period (Calendar Days) | 60-90 | 45 | 45 | 45 | 45 | 60 |

Technical Breakthrough of BLL-30 & BLJ-20 Plastic to Fuel Machine

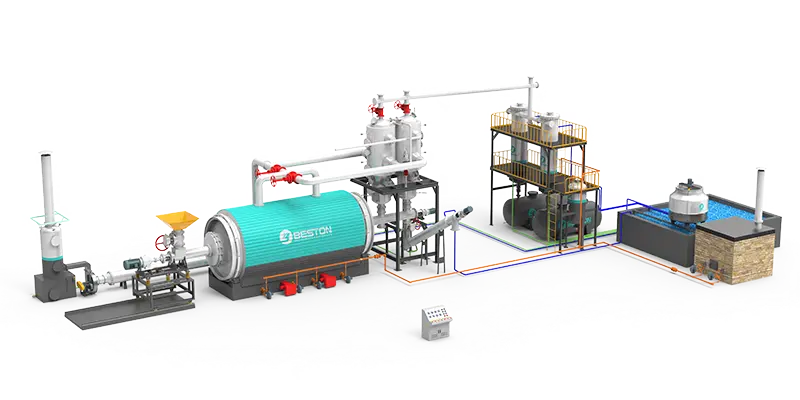

Model BLJ-20

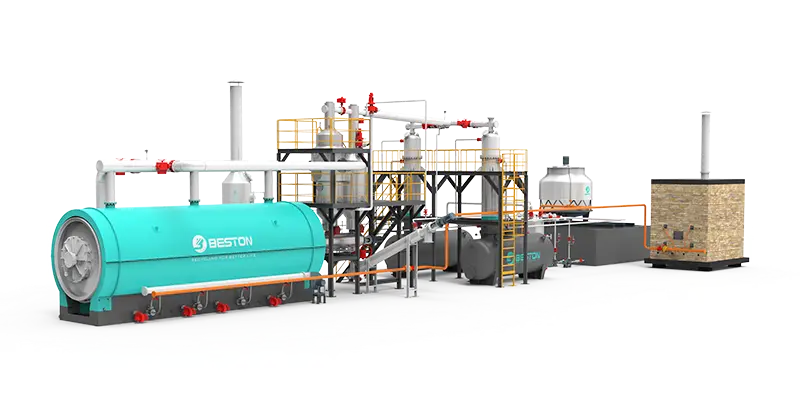

Model BLL-30

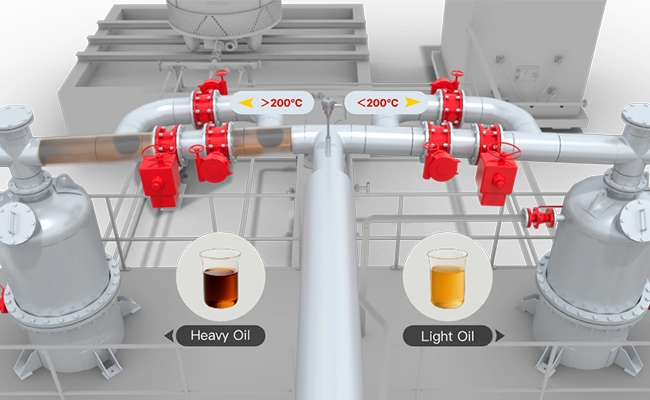

Fractional Distillation Technology

– Naphtha & Diesel in One Step

BLJ-20 integrates pyrolysis and distillation. Fractions with a boiling point below 200 °C are directed to the light oil tank as naphtha, while those above 200 °C flow into the heavy oil tank as non-standard diesel. It delivers:

- Boost Oil Value: High-grade product mix raises the overall market price of pyrolysis oil.

- Lower OPEX: Cuts equipment, land, labor, and energy costs by eliminating extra distillation steps.

Large-Capacity Main Reactor

– Ø2800×10000, 50% More Throughput

BLJ-20 main furnace increases processing efficiency compared to traditional plastic pyrolysis solutions: 8–10 T/D to 12–13 T/D, It creates:

- Higher Profit Margin: Expanded capacity raises daily output and revenue streams.

- Scalable Investment: One unit replaces multiple smaller reactors, simplifying layout and cutting project complexity.

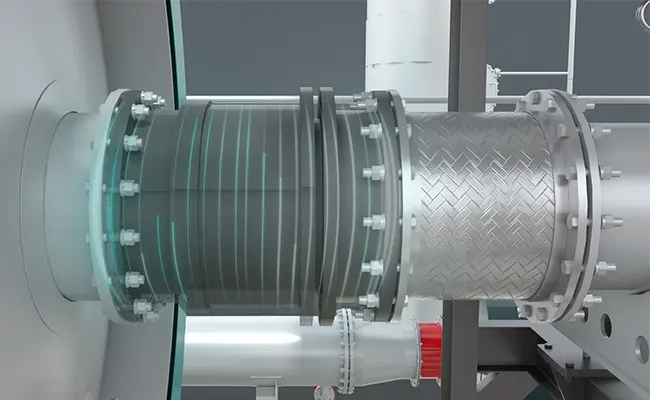

Thermo-Dynamic Sealing & Flexible Insulation

– Safer, Cleaner Operation

Advanced sealing prevents oil-gas leakage, while high-temperature insulation minimizes thermal hazards. BLJ-20 plastic into fuel machine ensures no visible flames and a safer working environment. It delivers:

- Ensure Compliance: Achieves strict environmental standards while enhancing on-site safety performance.

- Safeguard Workforce: Reduces exposure to fumes and heat, showing human-centered design and care for operator health.

Anti-Polymerization in Oil‑Gas Condensation

– 30 Days Continuous Run

It prevents olefins blocking oil‑gas lines by anti‑polymerizing. Thus, plastic into fuel machine achieves 30 days non-stop running, creating following value:

- Avoid Downtime Loss:Ensures steady pyrolysis output. Cuts revenue loss and delivery delays from shutdowns.

- Get Higher ROI:Lower failure rates reduce repair, parts, and labor costs, while stable output drives consistent, long-term returns.

Hot Flue Gas Recycling & Air Preheating

– 55% Less Fuel Use, 50% Less Emissions

This system recycles 80% of furnace flue gas and mixes it with hot air to heat pyrolysis plant. The other 20% preheats fresh combustion air. It achieves:

- Save Fuel Cost: Reuses heat to cut fuel use by 55%, slashing operating expenses.

- Ensure Compliance: Exhaust meets EU standards, which keeps production legal, and avoids fines.

Furnace Automatic Temperature Control

– 80% Less Manual Work

The main furnace auto‑adjusts for different fuels with ±10 °C precision. Combined with continuous feeding and discharging, it delivers:

- Lower Workload: One‑touch operation removes the need for constant checks and adjustments.

- Cut Labor Cost: High automation means only 2 operators are needed, saving cost on skilled labor.

Best Practices: Plastic-into-Fuel Pyrolysis Projects Across the Globe

Application Oil Products from Plastic into Fuel Machine

Pyrolysis Oil

Alternative Fuel

- High-temperature industrial furnaces in industrial plants use pyrolysis oil as fuel.

- During preheating stage, pyrolysis oil can be used as fuel for combustion system of plastic into fuel machine.

Non-Standard Diesel

Higher Grade Fuel

- Heavy oil generator sets can use non-standard diesel to generate electricity.

- Some large industrial machinery can use non-standard diesel as fuel.

Naphtha

Sustainable Industrial Material

- In the plastics manufacturing industry, naphtha is the main raw material for ethylene extraction;

- Naphtha can be used as a basic component for gasoline blending;

Identifying Plastic for Plastic to Fuel Machine: Classification Guide

Applicability Analysis

| Types of Plastic | Coming from | Applicability | |

|---|---|---|---|

|

Polyethylene Terephthalate | Transparent bottles & packaging etc. | × |

|

High-Density Polyethylene | Plastic pallets, trash cans, etc. | √ |

|

Polyvinyl Chloride | Building materials, cable sheaths, circuit boards | × |

|

Low-Density Polyethylene | Cling films, freshness protection bags, etc. | √ |

|

Polypropylene | Microwave lunch box, fresh-keeping box, etc. | √ |

|

Polystyrene | Fast food box, bowl of instant noodles box, etc. | √ |

|

Other Plastics without chlorine and oxygen | Various sources | √ |

|

Other plastics with chlorine and oxygen | Various sources | × |

Oil Yield Analysis

Note:

- Plastics containing oxygen(PET) and halogen elements(PVC) are not suitable. Oxygen-containing plastics pose reaction safety hazards. Combustion of fuel oil containing halogen elements may generate dioxins.

- Oil yield is based on laboratory data from a single plastic type. It is for reference only. Oil extraction effect of the material needs to be tested through experiments by plastic to oil plant.

Plastic to Fuel Conversion: Sustainable Power of Catalytic Pyrolysis

01 Plastic Feeding

You have a variety of feeding methods to choose from, including manual feeding, hydraulic feeding, and screw feeding.

02 Oil‑Gas Formation

- After the plastic enters the pre‑heated plastic pyrolysis chamber, the pyrolysis reaction begins.

- When the reaction temperature reaches 180 ℃, oil and gas start to form in the furnace.

- At 280–350 ℃, oil and gas are produced on a large scale.

03 Oil‑Gas Condensation

- High‑temperature oil and gas enter the catalytic tower and manifold, where waxy and heavy oils are separated.

- Condensable oil gas passes through the oil‑channel condenser; the resulting plastic pyrolysis oil flows into the oil‑storage tank.

04 Solid‑Residue Discharge

A three‑channel water‑cooled slag‑discharge system can achieve high‑temperature slagging while saving cooling time, lowering the final slag temperature to 50–80 ℃.

05 Gas Treatment

- Non‑condensable syngas enters the water seal. After purification, it is recycled to the reactor to provide heat. Excess syngas is burned in the exhaust chamber or collected as fuel.

- High‑temperature exhaust gas first passes through a flue condenser to cool, then through a cooling tower and spray tower for dust removal.

A high‑end exhaust‑gas treatment system can be selected so that final emissions meet EU standards.

Current Dilemma of Waste Plastic Recycling

tons Plastic Production per year

tons Directly into Ocean per year

tons Carbon Emissions from Incineration per year

years Degradation Time

Disposal Method of Waste Plastic

Negative Impacts of Discarded Plastic

Ecological Threats

- Land: Plastic waste accumulated in the soil for a long time will hinder soil fertility, aeration and water penetration. This affects plant growth.

- Atmosphere: During incineration of plastics, harmful substances, especially dioxins and polychlorinated biphenyls, are released. It negatively affecting air quality.

- Ocean: Discharge of plastic into the ocean leads to marine life ingesting the plastic. In addition, harmful microplastics are passed throughout the food chain.

Resource Consumption

- Social Resource: Disposal of plastic requires a large amount of social resources. Recycling plastic waste requires huge amounts of money to set up and maintain recycling facilities. Meanwhile, plastic recycling projects also involve significant labor, technical and managerial staff.

- Fossil Resource: Lack of effective plastic recycling methods leads to significant waste accumulation. However, plastic production heavily relies on non-renewable fossil fuels such as crude oil and natural gas. Neglect of discarded plastics means the unsustainable consumption of fossil resources.

Energy Transition is Imminent

Traditional Fossil Energy Faces Difficulties

- Fossil Fuel Dominance: The current energy mix includes 30% crude oil, 25% coal, 25% natural gas, 15% alternative energy, and 5% nuclear. Fossil fuels still dominate globally, driving continued greenhouse gas emissions.

- Transition in a Dilemma: Fossil fuel reserves are shrinking, threatening energy security. Yet, their massive infrastructure makes transition costly and time-consuming.

Chance and Challenge Coexist in Alternative Fuels

- Clean Fuels from Waste: Alternative fuels like pyrolysis oil, biogas, and bioethanol are made from waste (plastics, tyres, biomass). They emit less pollution and help reduce reliance on fossil fuels.

- Technical & Cost Barriers: Some alternative fuels are still developing and face technical challenges. High startup and production costs require ongoing innovation and cost control to compete with fossil fuels.

Current Opportunities for Plastic to Fuel Business Plan

Currently, plastic bans are prevalent around the world. Even if some areas do not implement this policy, plastic recycling remains an important part of environmental protection policies. Therefore, the plastic to fuel machine has good prospects for development.

Huge Recycling Demand

Huge Recycling Demand

With plastic bans in place, demand for alternative ways to deal with plastic waste is likely to surge. Additionally, increased awareness of environmental issues and demand for sustainable practices may prompt consumers and industry to support recycling initiatives. This is undoubtedly a boost to the plastics to fuel business plan.

Government Policy Incentives

Government Policy Incentives

Governments often create policies and incentives to promote eco-friendly technologies. In response to a plastic ban, governments may offer incentives, subsidies or tax breaks to companies working on innovative recycling methods, such as plastic fuel technology. Recyclers can take advantage of government support to reap financial benefits and grow their businesses.

Plastic Industry Transformation

Plastic Industry Transformation

Plastic bans require the plastics industry to shift in a more sustainable direction. This transformation is in line with the overall trend of circular economy and sustainable resource management. Plastic to fuel technology can position itself as key players in this evolving landscape. This thus contributes to the sustainable development of the plastics industry.

Beston Group Bring Innovations to Plastic Recycling Worldwide

As an experienced manufacturer and solution provider, Beston Group meets various plastic recycling challenges with high manufacturing standards and strong R&D capabilities. We can provide you with excellent quality equipment at reasonable plastic to fuel machine price. In addition, Beston Group is consistently enhancing R&D efforts in converting plastic into high-quality fuel. We hava established long-term and stable cooperative relationships with many customers. Here are some successful cases for your reference.

Partner with Beston

Plastic to fuel machine contributes to sustainable waste management. If you would like to get involved in a plastic recycling project, contact us! Just tell us your needs and Beston Group will customize a professional plastic recycling solution for you. In particular, if you want to know more information related to solid waste recycling, you can follow us on LinkedIn.