Palm kernel shell charcoal machine is very popular on the market now. The machine uses pyrolysis technology to make charcoal from palm kernel shells. Owing to the high value of utilization of palm kernel shell charcoal, this machine is very rewarding and it can help investors earn money from palm kernel shells. If you are interested in producing charcoal from palm kernel shells, keep reading to learn more details.

Two Technical Breakthroughs of BST-50S Palm Kernel Shell Charcoal Machine

Tar and Dust Self-Cleaning System

BST-50S palm shell charcoal machine introduces a fully upgraded tar and dust self-cleaning system. This automated mechanism continuously removes tar residues and dust deposits from pipelines without the need for manual intervention. With this breakthrough, the machine is capable of:

- Producing 6,000 tons of biochar annually

- Sequestering 12,000 tons of carbon

- Maintaining stable operation for 7,200 hours per year

Dual-barrel Rotary Reactor

BST-50S charcoal making machine is equipped with an advanced dual-layer rotary reactor. This innovative design incorporates two concentric cylinders: the inner barrel performs rapid pre-drying of feedstock, while the outer barrel carries out deep pyrolysis. With this structural innovation, the machine can:

- Handle more than 10 m³ of feedstock per hour

- Deliver high-quality biochar through deep material treatment

- Optimize land use with its compact dual-layer configuration

Beston + Puro.earth: Empower Your Carbon Removal Project

Beston Group is thrilled to be recognized as the technology partner of Puro.earth, the world’s leading crediting platform for engineered carbon removal. Our palm kernel shell charcoal making machine (BST-50S model) has passed this carbon removal platform’s evaluation. Explore how this benefits your investment.

Get Technologies & Products Meeting CDR Standards

Choosing Beston BST-50S biochar making machine, enterprises can obtain:

- Technology Meets Puro.earth Standard: Puro.earth has vetted the biochar pyrolysis technology in BST-50S Model.

- Biochar Meets EBC Standard: Puro.earth has vetted that BST-50S machine can produce high-quality biochar, which meets most of the applications under the EBC (European Biochar Certificate) standards.

Shorten CORCs Approval Cycle

Puro.earth is a globally recognized pioneer in the carbon removal and carbon credit industry, with its evaluation holding high international authority.

Therefore, investors eying carbon trading choose BST-50S Model can reduce the waiting time for the certification of Carbon Dioxide Removal Certificates (CORCs). This helps them better enter the carbon trading market.

Reduce Project Risks of Biochar Carbon Sink

In carbon removal and carbon credit projects, compliance and sustainability are crucial. Therefore, using a vetted BST-50S palm kernel shell charcoal machine can ensure the stability and reliability of the biochar production process. This can reduce the risk of project failure due to technical or environmental issues.

Enhance Brand Trustworthiness

When investors use BST-50S palm kernel shell charcoal machine vetted by Puro.earth, they can send a positive environmental signal to the market and consumers. This helps establish a favorable brand image in the fields of carbon trading. This will strengthen the trust of customers, partners, and investors and attract more attention and support.

2 Models Palm Kernel Shell Charcoal Machine for Sale

Model BST-50

- BST-50S technology vetted by puro.earth

- 6,000 tons biochar production annually

- 7200H/Y stable&safe operation

- 4 Configuration options

Model BST-06

- 8000H/Y stable&safe operation

- Low-cost carbon removal process verification

- Small-scale test machine

- 2 Configuration options

| Model | BST-50 Standard | BST-50S LM | BST-50S HM | BST-50S MAX | BST-06 Standard | BST-06MAX |

|---|---|---|---|---|---|---|

| Time to Market | 2015 | 2022 | 2022 | 2022 | 2025 | 2025 |

| Operating Mode | Continuous | Continuous | Continuous | Continuous | Continuous | Continuous |

| Application | Commercial Scale | Commercial Scale | Commercial Scale | Commercial Scale | Testing | Testing |

| Dust Removal System | Standard | Advanced | Advanced | Advanced | Standard | Advanced |

| Feeding Capacity | 10-15m³/h | 10-15m³/h | 10-15m³/h | 10-15m³/h | 100-300KG/H | 100-300KG/H |

| Biochar Discharge Temperature | 45℃ | 45℃ | 45℃ | 45℃ | 45℃ | 45℃ |

| Puro.earth Authentication Model | × | √ | √ | √ | × | |

| Maximum Pyrolysis temperature | 650℃ | 650℃ | 650℃ | 850℃ | 650℃ | |

| Service Life | 5-8 years | 5-8 years | 5-8 years | 8-10 years | 5-8 years | |

| Annual Operating Time | 7200 hours | 7200 hours | 7200 hours | 7200 hours | 8000 hours | |

| Land Space Required (L*W*H*m) | 35m×15m×8m | 65m×15m×8m | 65m×15m×8m | 65m×15m×8m | 25m*18m*6m | |

| Total Power (KW) | 201.25kW | 453.35kW | 505.35kW | 505.35kW | 129.79 | 162.79 |

| Cooling Method | Recycling cooling Water | Industrial chiller | Industrial chiller | Industrial chiller | Recycling cooling Water | Industrial chiller |

| Installation Period (Calendar Days) | 50 | 70 | 70 | 70 | 45 | 50 |

Know Palm Kernel Shells in Palm Cultivation and Palm Oil Industry

Palm Kernel Shell (PKS) is the hard outer shell of palm kernel fruit, which is left behind as a byproduct after palm oil extraction. It is a fibrous, brownish-yellow material with particle sizes typically ranging from 5 mm to 40 mm. Each year, the palm oil industry generates over 5 million tons of PKS. Utilizing a palm shell charcoal machine allows you to profit from the attractive palm kernel shell charcoal price. Now learn about this material.

Major Producing Regions

Major Producing Regions

The primary producers of PKS are countries where oil palm is a major economic crop. According to public data, the top PKS-producing regions include:

- Indonesia

- Malaysia

- Thailand

- Brazil

- Colombia

- etc.

Characteristics of Palm Shells

Characteristics of Palm Shells

Palm kernel shells offer unique characteristics that make them ideal for charcoal production.

- High calorific value (around 4000 Kcal/kg)

- Low moisture content

- Easy crushing

- Low ash content

- Renewable, easy available and low cost

Palm Byproducts for Pyrolysis

Palm Byproducts for Pyrolysis

In addition to PKS, some other palm byproducts be processed through pyrolysis.

- palm fiber;

- empty fruit bunches (EFB);

- palm dregs;

- palm branches and leaves;

- etc.

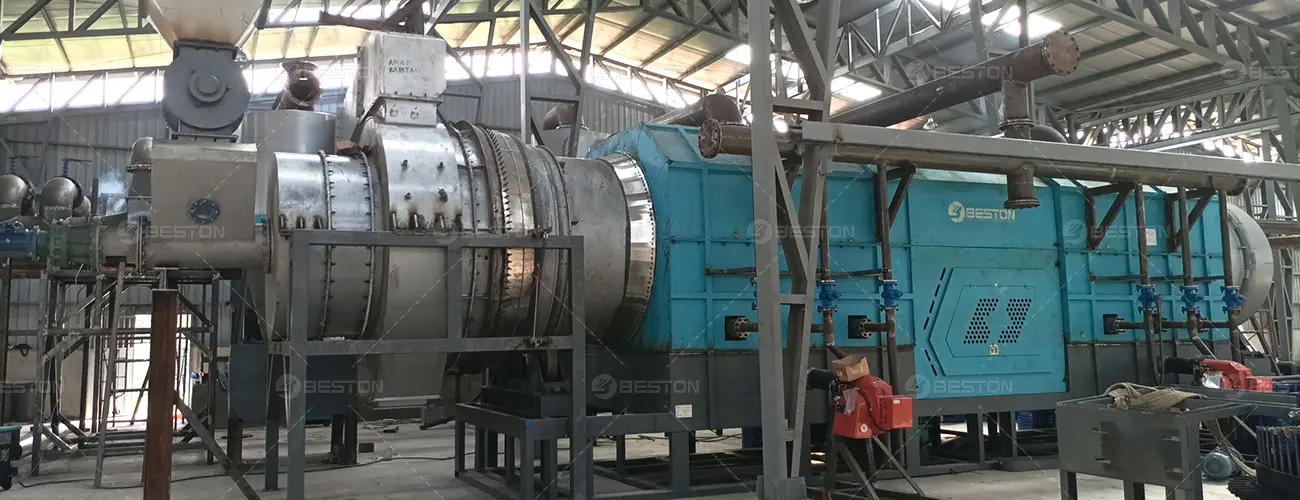

Apply Continuous Palm Kernel Shell Charcoal Machine to Recycle Biomass

To fully utilize palm waste in palm cultivation and the palm oil industry, please find a high-efficiency continuous palm shell charcoal machine. After relentless efforts, Beston Group has achieved a critical breakthrough in continuous biomass pyrolysis technology, delivering higher efficiency and stability to customers. This technological advancement brings such benefits:

- Resolve issue of tar and wood vinegar liquefaction.

- Resolve issue of carbon powder buildup in pipelines.

Achieved a breakthrough from 120 hours to 360 hours and 720 hours of continuous operation within four months.

- Significantly reduce downtime and maintenance costs.

- Increase the whole pyrolysis production efficiency.

- Maximize biochar’s potential in carbon sequestration.

- Help investors enter the carbon sink market.

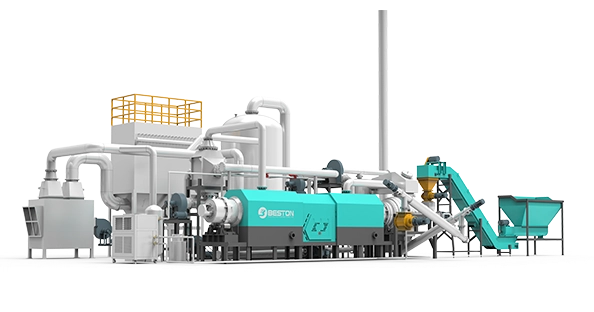

How to Make Charcoal from Palm Kernel Shell?

A complete palm shell charcoal machine usually includes a material pretreatment line, a biomass pyrolysis part, and a charcoal briquette machine. This integrated system effectively transforms palm waste into valuable charcoal, optimizing the process for both efficiency and sustainability. See its working process.

01 Raw Material Pretreatment

Before feeding the palm kernel shells into the reactor, they need to be prepared properly:

- Drying: Dry the shells with the dryer to keep their moisture content below 15%.

- Size Reduction: If the shells are too large, they may need to be crushed or shredded into smaller pieces (5-20mm) for uniform processing.

02 Palm Kernel Shells Feeding

Once ready, feed them into the reactor of the palm kernel shell charcoal making machine.

03 Palm Kernel Shells Pyrolysis/Carbonization

The machine will then begin the pyrolysis process. During this stage, the palm kernel shells release volatile gases, leaving behind solid carbon (biochar). The temperature in the reactor are crucial for achieving the desired quality of biochar.

- Medium-temperature zone: In the inner cylinder of reactor, biomass materials undergo secondary drying and semi-carbonization.

- High-temperature zone: Then the screw pushes them to drop into the outer cylinder of reactor for complete pyrolysis, producing biochar.

04 Biogas Recovery

As the shells undergo pyrolysis, biogas are purified the impurities so that it can be used as combustible gas to provide energy for the palm kernel shell charcoal machine.

05 Palm Shell Charcoal Collection

Characteristics of Pyrolysis Palm Biochar: Test Report

Note: The following are the test data for palm shell biochar produced by palm shell charcoal machine. The data may vary due to material differences.

| Results: | |

|---|---|

| NO | 1# |

| Kind | Palm kernel shell |

| Size | 5-20mm |

| Whole water Mt% | 2.35 |

| Analytical water Mad% | 1.32 |

| Dry basis ash Ad%7 | 7.91 |

| Volatile matter Vd% | 9.32 |

| Dry basis fixed carbon Fcad% | 77.36 |

| Sulfur content on dry basis St.d% | 0.08 |

| Coking Characteristics 1-8CRC | 1 |

| New national standard calorimeter dry basis high calorific value kcal/kg | 5485 |

| The new national standard calorimeter method receives the base low calorific value kcal/kg | 5265 |

| Remarks:

**℃ Out of water and oil, the highest temperature **℃ The above data is for reference only |

|

Remarkable Uses of Palm Kernel Shell Charcoal

Soil Remediation in Agriculture

Livestock Breeding Feed

Alternative Fuel

Metallurgy

BBQ Charcoal

Carbon Removal

Decarbonization Building Materials

From Waste to Value: Environmental Impact of Palm Kernel Shell Charcoal Machine

In tropical and subtropical regions, palm kernel shells are abundant, and palm shell charcoal machine offers a practical solution for their utilization. The following points highlight the key environmental advantages of this technology.

Reduce Agricultural Waste Pollution

Palm kernel shells, as by-products of the palm oil industry, are often stockpiled or openly burned, causing soil and air pollution. Through pyrolysis, these low-value residues are transformed into valuable resources, reducing the environmental burden.

Cut Carbon Emissions for Sustainability

Palm kernel shell charcoal serves as an alternative to fossil fuels, reducing dependence on coal and oil. This substitution lowers carbon emissions and supports the transition toward sustainable energy use.

Drive Circular Economy and Green Industry

Converting waste into economic products embodies the concept of a circular economy. Palm kernel shell biochar projects also generate new jobs and extend the industrial chain, fostering a transition toward green and sustainable regional development.

Operation Guarantee of Palm Shell Charcoal Machine

Multiple Safety Assurance

- Explosion-Proof Components: Include explosion-proof water seals and valves, explosion-proof holes, etc.

- Slight Negative Pressure Operation: Prevent excessive pressure within the palm kernel shell charcoal making machine.

- Alarm System in Electric Control Cabinet: Promptly issues an alarm to alert operators if any electrical fault occurs.

- Three-Layer Seals & Closed-Air Feeding Design: Prevent oxygen intake to ensure safety.

Environmental Compliance Guarantee

- EU Standard Dedusting Technology: A multi-layer de-dusting system can make gas emissions meet strict EU standards.

- Water Resource Reuse: Water resources are frequently recycled to minimize wastage.

- Flue gas & Syngas Utilization: Reuse hot flue gas for material drying which cuts energy loss; Recycle syngas to fuel biochar reactor, conserving fossil fuel resources.

- Additive-Free Production: The production process uses no additives or chemicals, ensuring environmental safety.

Efficient Operation Assurance

- Double-Return Heating Structure: Double the thermal utilization efficiency and realize full carbonization of palm kernel shells.

- Intelligent Control Technology: Ensure timely data feedback of palm kernel shell charcoal machine and optimized operation.

- Advanced Insulation System: Prevent biomass from contacting smoke or hot gases, ensuring uncontaminated production and minimizing heat loss.

- Low-Nitrogen Combustion Design: Boost combustion efficiency, reducing energy waste.

Global Partnerships of Palm Shell Charcoal Machine

Beston palm kernel shell charcoal machine actively transforms biomass like coconut shells, wood chips, bamboo, rice husks, and more into valuable charcoal. Beston Group partners with customers worldwide, offering comprehensive support. Explore how we can help customers succeed.

Get Your Palm Waste Recycling Solution Today

Start recycling palm waste with the palm kernel shell charcoal machine. This efficient system produces high-quality biochar, offering both economic benefits and environmental sustainability. Contact Beston Group anytime—our experts are ready to guide your project. Follow us on LinkedIn for the latest updates and insights!