Coffee husk charcoal making machine is a key innovation in achieving carbon-neutral agriculture. Pyrolysis technology converts coffee husks, a major agricultural waste product, into stable biochar/charcoal. This process not only directly sequesters carbon but also provides a renewable energy alternative to fossil fuels using charcoal. Coffee husk charcoal machine transforms a waste disposal problem into a climate solution. Furthermore, it advances sustainability and carbon reduction goals across the entire coffee value chain.

Tremendous Potential of Waste Coffee Husks as a Resource

Enormous Coffee Production

Coffee thrives in tropical and subtropical regions, such as Brazil, Vietnam, Indonesia, Colombia, Ethiopia. There have consistent rainfall, moderate temperatures to create ideal growing conditions. In the 2024/2025 season, global coffee production reaches 174.4 million 60 kg bags. Brazil remains the largest contributor. It produces 64.7 million bags, nearly 4 million tons. 3% year-over-year global increase reflects the continued strong growth in global coffee cultivation.(Source: USDA Foreign Agricultural Service)

Coffee Husk Recovery & Utilization

The booming coffee market also brings massive waste. Each ton of processed coffee generates about 0.2 tons of husks, meaning nearly 2 million tons are produced globally each year. Conventional reuse—through composting, fuel, or soil amendment—faces limits due to the husk’s tough fibers, caffeine, and tannins. Today, pyrolysis system recycling is emerging as a promising solution. It transforms coffee husks into biochar/charcoal for carbon removal and sustainable fuel resource.

Pyrolysis-Based Coffee Husk Charcoal Making Machine for Recycling

Raw Material Compatibility

Coffee husk typically has a moisture content of 10–15% and high lignin & cellulose content. It makes coffee husk well-suited for pyrolysis process. Furthermore, it has low bulk density, low ash content. These factors make coffee husk more easily charcoal-efficient in charcoal machine compared to agricultural waste such as rice husks and straw.

CDR Market Validation

Biochar produced from coffee husks can stably store carbon for centuries. The carbon credits they generate can be sold. Biochar is a mainstream carbon removal method in the CDR market. In major coffee-producing regions, such as Brazil, projects are already underway to convert waste into energy and generate carbon credits through pyrolysis.

Environmental Feasibility

Pyrolysis is under anoxic conditions and adopts exhaust gas treatment facilities. This produces virtually no smoke or hazardous gases. Therefore, coffee husk charcoal mkaing machine can address the issues of high caffeine content and tannin toxicity. This avoids the leachate and odor pollution associated with composting or incineration.

Economical Availability

Combustible gas from pyrolysis can serve as self-generation, reducing energy costs. Furthermore, coffee husk charcoal/biochar has a high market value. In addition to being sold as carbon credits, it is also popular among consumers in high-value-added markets such as agriculture, building materials, animal husbandry, and industrial energy substitution.

Puro.earth-vetted Pyrolysis Technology: Boost Coffee Husk Recycling Value

Beston Group’s coffee husk charcoal making machine (BST-50S Model) has passed Puro.earth evaluation, a globally recognized platform for carbon removal. This accomplishment will add value to our customers’ coffee husk recycling initiatives in different aspects.

Earn Carbon Credits Opportunities

To secure carbon credit benefits, the carbon footprint of biochar production must be significantly lower than the carbon reduction achieved by the project. Beston’s compliant technology and equipment (BST-50S Model) precisely meet this requirement, allowing carbon credit opportunities.

Increase Biochar Added Value

The controlled conditions of the pyrolysis process, vetted by Puro.earth, produce more consistent and high-grade coffee husk biochar. It meets most applications under the EBC standards and can be applied in fields such as agriculture, carbon removal, thus enhancing market competitiveness and economic value.

Build Sustainability Image

By adopting our vetted BST-50S machine, your project actively promotes sustainability and circular economy principles within the coffee and related industries. This enhances your brand’s green reputation.

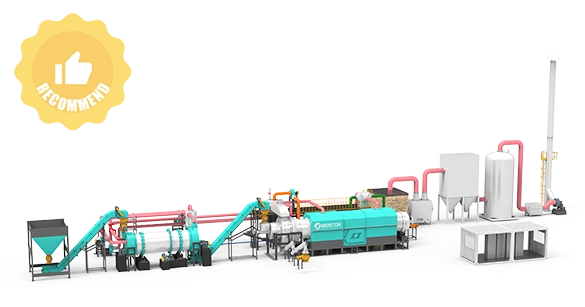

Beston Coffee Husk Charcoal Making Machine for Sale

The coffee husk biochar production equipment processes coffee husks into coffee husk charcoal. Beston Group offers the following 2 models according to the different needs of customers. Please see the details below.

Model BST-50

- BST-50S technology vetted by puro.earth

- 6,000 tons biochar production annually

- 7200H/Y stable&safe operation

- 4 Configuration options

Model BST-06

- 8000H/Y stable&safe operation

- Low-cost carbon removal process verification

- Small-scale test machine

- 2 Configuration options

| Model | BST-50 Standard | BST-50S LM | BST-50S HM | BST-50S MAX | BST-06 Standard | BST-06MAX |

|---|---|---|---|---|---|---|

| Time to Market | 2015 | 2022 | 2022 | 2022 | 2025 | 2025 |

| Operating Mode | Continuous | Continuous | Continuous | Continuous | Continuous | Continuous |

| Application | Commercial Scale | Commercial Scale | Commercial Scale | Commercial Scale | Testing | Testing |

| Dust Removal System | Standard | Advanced | Advanced | Advanced | Standard | Advanced |

| Feeding Capacity | 10-15m³/h | 10-15m³/h | 10-15m³/h | 10-15m³/h | 100-300KG/H | 100-300KG/H |

| Biochar Discharge Temperature | 45℃ | 45℃ | 45℃ | 45℃ | 45℃ | 45℃ |

| Puro.earth Authentication Model | × | √ | √ | √ | × | |

| Maximum Pyrolysis temperature | 650℃ | 650℃ | 650℃ | 850℃ | 650℃ | |

| Service Life | 5-8 years | 5-8 years | 5-8 years | 8-10 years | 5-8 years | |

| Annual Operating Time | 7200 hours | 7200 hours | 7200 hours | 7200 hours | 8000 hours | |

| Land Space Required (L*W*H*m) | 35m×15m×8m | 65m×15m×8m | 65m×15m×8m | 65m×15m×8m | 25m*18m*6m | |

| Total Power (KW) | 201.25kW | 453.35kW | 505.35kW | 505.35kW | 129.79 | 162.79 |

| Cooling Method | Recycling cooling Water | Industrial chiller | Industrial chiller | Industrial chiller | Recycling cooling Water | Industrial chiller |

| Installation Period (Calendar Days) | 50 | 70 | 70 | 70 | 45 | 50 |

How to Make Charcoal from Coffee Husk?

In the BST series, the size of coffee husks ranges from 5-20mm (with an optimal size of 5-8mm), with a moisture content of ≤15%.

How to Apply Coffee Husk Charcoal?

Industrial Fuel

Soil Improvement

BBQ

Carbon Sequestration

Metallurgy

Hookah

Animal Feed Additive

Report of Coffee Husk Charcoal After Pyrolysis

Here is a composition report of coffee husk charcoal processed by the our equipment. It can be observed that the carbon content is high, while the ash content is relatively low. This raw material is sourced from China. Different types of raw materials, moisture levels, and particle sizes can affect the composition analysis of final charcoal. The following report is for reference only. If you would like to know the composition of your raw materials after biomass pyrolysis, please send us a sample. We will provide you with a professional data report.

| Results: | |

|---|---|

| NO | 1# |

| Kind | Waste Coffee Husks |

| Total Moisture Mt% | 11.78 |

| Analytical Water Mad% | 1.21 |

| Dry Basis Ash Ad% | 2.75 |

| Volatile Matter on Dry Basis Vd% | 30.96 |

| Fixed Carbon Fcad% | 65.08 |

| Sulfur Content on Dry Basis St.d% | 0.02 |

| Coking Characteristics 1-8CRC | |

| New national standard calorimeter dry basis high calorific value kcal/kg | 7050 |

| The new national standard calorimeter method receives the base low calorific value kcal/kg | 6053 |

| Remarks: **℃ Out of water and oil, the highest temperature **℃ The above data is for reference only |

Signature: |

Features of Coffee Husk Charcoal Making Machine

Intelligent Control

Utilizing PLC smart control technology to achieve real-time monitoring of pipeline issues.

The Internet of Things (IoT) system can remotely assist in monitoring project operation status.

Quality Control

Each biochar pyrolysis equipment follows standardized quality inspection procedures.

Before leaving the factory, the equipment undergoes inspections from three departments to ensure flawless performance.

Safe Operation

The equipment operates under a slight negative pressure environment and is equipped with explosion-proof vents and other safety detection devices.

The PLC control panel is equipped with an alarm system to ensure safe operation.

Energy Saving

Partial fuel costs can be saved through combustible gas recovery.

Continuous equipment adopts a dual-return heating structure, increasing thermal efficiency by more than double.

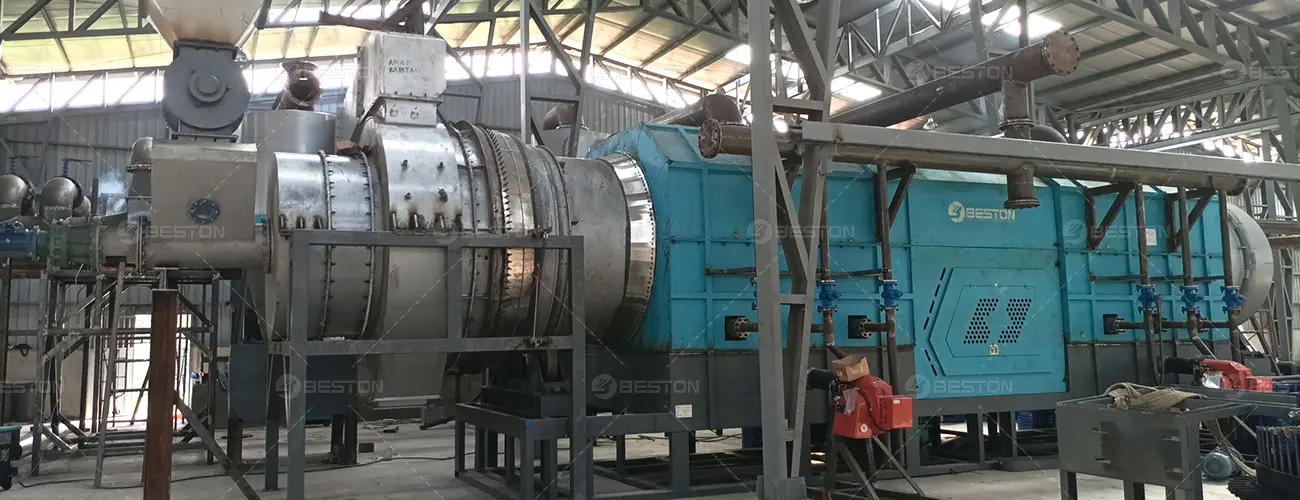

Biomass to Charcoal Making Machine Projects

Coffee husk charcoal making equipment converts various resources into biomass charcoal, including coffee husks, coconut shells, sawdust, and so on. Customers utilize these biochar equipment not only to convert coffee husks and other biomass resources into biomass charcoal but also to generate economic benefits from it. They expand their business channels through this industry and achieve circular economy. Below are some case studies.

Start Your Coffee Husk Charcoal Business with Beston Group

Coffee husk charcoal making machine expands the industry chain of the coffee industry. By converting various coffee husks into biomass charcoal, this technology effectively utilizes what was previously considered waste, helping to reduce environmental pollution and resource wastage. Moreover, this production and operation method aligns with the concept of sustainable development. If you are interested in this equipment and solution, please feel free to contact Beston Group and see more industry news on LinkedIn. Let’s work together to actively promote the development of the project.