Carbonization machine plays an important role in addressing the growing problem of biomass waste accumulation. It not only reduces the volume of agricultural and forestry residues but also transforms them into valuable biochar. In this way, it offers both environmental and economic benefits, making it a practical solution for sustainable waste management. If you have similar needs, please continue reading to explore more details.

What Is A Carbonization Machine?

A carbonizer machine is a type of industrial biochar production equipment designed to thermally treat biomass under low-oxygen conditions. By heating the material to around 380–450°C, it removes moisture and unwanted substances. The product is stable, carbon-rich biochar, along with useful by-products like combustible gas. This process makes the conversion efficient and improves the quality of the final product.

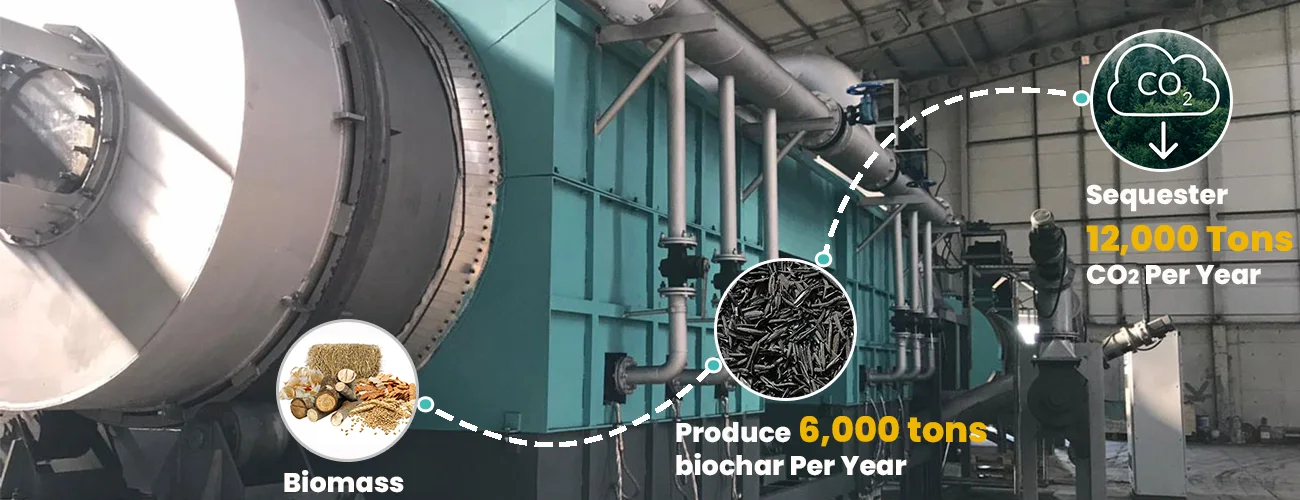

Two Technologies Make BST-50S a Benchmark for Carbon Reduction

Tar Dust Self-cleaning Technology

The self-cleaning system uses a gas flushing mechanism to remove tar and dust accumulations from the pipeline, ensuring smooth transmission. This design enables:

- Safe and stable operation for 7,200 hours per year

- Annual production of 6,000 tons of biochar

- Annual carbon sequestration of 12,000 tons

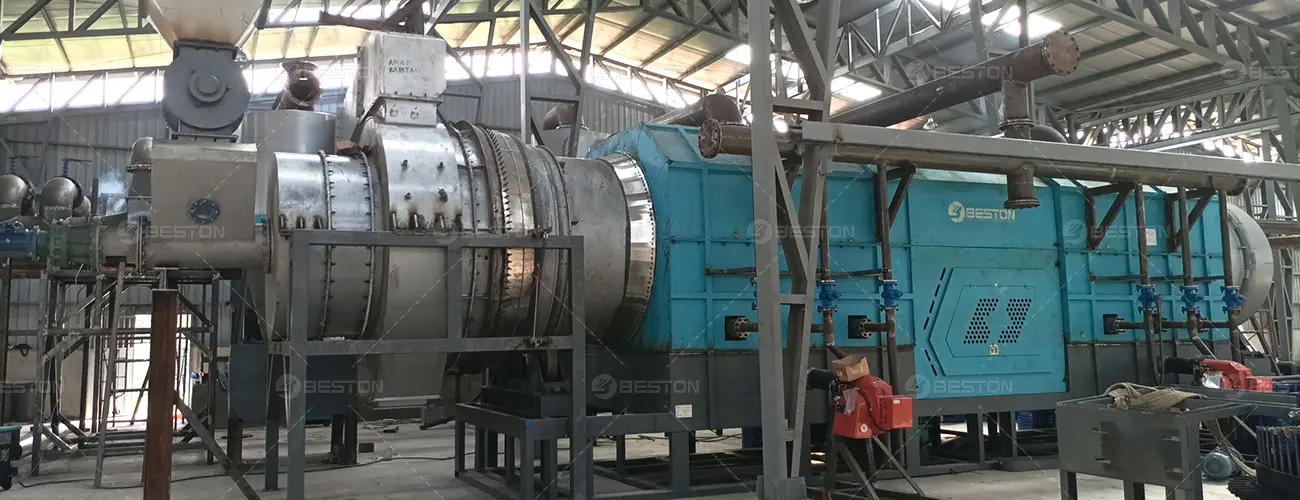

Dual-cylinder Rotary Core Kiln

The core component of the carbonization machine is the reactor, which uses a dual-cylinder structure. The inner cylinder pre-dries the biomass, while the outer ensures complete carbonization. This design guarantees:

- Process capacity of more than 10 m³ per hour

- High thermal efficiency via inner–outer cylinder heat recycling

- Ensure high fixed carbon content and stable biochar quality

Parameters of Beston Biomass Carbonization Machine for Sale

Model BST-50

- BST-50S technology vetted by puro.earth

- 6,000 tons biochar production annually

- 7200H/Y stable&safe operation

- 4 Configuration options

Model BST-06

- 8000H/Y stable&safe operation

- Low-cost carbon removal process verification

- Small-scale test machine

- 2 Configuration options

| Model | BST-50 Standard | BST-50S LM | BST-50S HM | BST-50S MAX | BST-06 Standard | BST-06MAX |

|---|---|---|---|---|---|---|

| Time to Market | 2015 | 2022 | 2022 | 2022 | 2025 | 2025 |

| Operating Mode | Continuous | Continuous | Continuous | Continuous | Continuous | Continuous |

| Application | Commercial Scale | Commercial Scale | Commercial Scale | Commercial Scale | Testing | Testing |

| Dust Removal System | Standard | Advanced | Advanced | Advanced | Standard | Advanced |

| Feeding Capacity | 10-15m³/h | 10-15m³/h | 10-15m³/h | 10-15m³/h | 100-300KG/H | 100-300KG/H |

| Biochar Discharge Temperature | 45℃ | 45℃ | 45℃ | 45℃ | 45℃ | 45℃ |

| Puro.earth Authentication Model | × | √ | √ | √ | × | |

| Maximum Pyrolysis temperature | 650℃ | 650℃ | 650℃ | 850℃ | 650℃ | |

| Service Life | 5-8 years | 5-8 years | 5-8 years | 8-10 years | 5-8 years | |

| Annual Operating Time | 7200 hours | 7200 hours | 7200 hours | 7200 hours | 8000 hours | |

| Land Space Required (L*W*H*m) | 35m×15m×8m | 65m×15m×8m | 65m×15m×8m | 65m×15m×8m | 25m*18m*6m | |

| Total Power (KW) | 201.25kW | 453.35kW | 505.35kW | 505.35kW | 129.79 | 162.79 |

| Cooling Method | Recycling cooling Water | Industrial chiller | Industrial chiller | Industrial chiller | Recycling cooling Water | Industrial chiller |

| Installation Period (Calendar Days) | 50 | 70 | 70 | 70 | 45 | 50 |

Beston Group Joins Puro.earth Technology Supplier Network

Beston Group is honored to become a technology partner of Puro.earth, a leading global platform for carbon removal. Vetted by Puro.earth, our carbonization machine (BST-50S Model) can ensure credibility and carbon removal market acceptance. Investors who purchase our BST-50S machine will find it easier to achieve carbon credit trading and project profitability. Now learn how the BST-50S offers a viable solution for carbon removal investment.

Technology Meets Puro.earth Standards

Our BST-50S biomass carbonization plant integrates advanced processes such as gas combustion, self-cleaning of tar and dust, and cooling dust removal. Puro.earth has vetted BST-50S’s excellent environmental and climate performance (in terms of air pollutant emissions, solid waste management, liquid waste treatment, and greenhouse gas emissions).

Biochar Quality Meets EBC Standard

Our BST-50S charcoal making machine has proven able to produce high-quality biochar that meets the stringent eligibility requirements set by the Puro Standard for CO₂ Removal Certificates (CORCs). The produced biochar complies with most applications under the EBC standards.

Technical Progress of Carbonizer Machine: 720h Continuous Operation

Beston Group has introduced a new-generation continuous biomass carbonization plant, also known as a biomass pyrolysis plant. In less than four months, we advanced its continuous operation capacity from 120 hours to 360 hours, and ultimately to an impressive 720 hours.

Types of Biomass Suitable for Carbonization Machine

The primary feedstock for a carbonization equipment is biomass, which can be broadly categorized into three types:

Forestry Waste

Refers to by-products from forestry and wood processing, including logs, wood chips, and sawdust.

Agricultural Waste

Includes various crop residues such as straw, rice husks, bamboo, and similar materials.

Food Processing Waste

Covers residues from food-related industries, such as coconut shells, palm shells, and peanut shells.

What is The Carbonization Process?

Carbonization is a process that involves heating organic materials in the absence of oxygen to produce valuable products. See details below.

01 Material Pretreatment

Pretreat raw materials to meet the feeding requirements, particularly for biomass:

- Dry biomass until the moisture content is below 15%.

- Crush biomass into sizes between 5-20mm.

02 Material Feeding

Feed the prepared organic materials into the carbonization furnace by screw belt conveyor. This ensures a steady flow of materials into the machine while preventing the entry of excess oxygen.

03 Carbonzation – Material Decomposition

04 End Products Collection

- For biochar collection, a water-cooling system safely discharges the biochar and keeps the biochar temperature below 45°C.

- For syngas recycling, Most of the syngas are recycled to fuel the carbonization machine. Any excess syngas is directed to the burning room, where it is completely combusted.

05 Exhaust Gas Treatment

Finally, de-dusting system removes any impurities from the final emission smoke, ensuring final emissions align with EU standards.

Explore Key Application Scenarios of Biomass Charcoal

Environmental and Agricultural Applications

Carbon Sequestration & Emission Reduction

Biochar acts as a stable carbon sink, locking atmospheric CO₂ into solid form for centuries. This reduces GHG emissions and supports climate mitigation efforts, aligning with international decarbonization policies.

Soil Remediation and Improvement

When applied to farmland, biochar made from carbonizing machine enhances soil structure, increases nutrient retention, and improves microbial activity. It reduces heavy metal toxicity and balances pH levels, creating more fertile land for sustainable agriculture.

Animal Feed Improvement Solution

In livestock farming, biochar is used as a dietary supplement to improve digestion, reduce methane emissions, and enhance nutrient absorption. This contributes to healthier animals and reduced environmental footprint from intensive farming operations.

Energy and Fuel Applications

Hookah Charcoal or Barbecue Charcoal Production

Charcoal made from carbonization machine can be further processed into high-quality hookah or barbecue charcoal (through charcoal briquette machine). Its uniform combustion, low smoke emission, and long burning time make it attractive for recreational and commercial grilling markets, offering a sustainable substitute for conventional wood charcoal.

Fuel Alternative Solution for Industry Plants

Biomass charcoal can act as a solid fuel, which can substitute coal or heavy oil in boilers, kilns, and furnaces. Its high calorific value and clean combustion reduce industrial emissions while offering a sustainable and cost-efficient energy source.

Carbonization Machine vs Traditional Kiln

Traditional kiln carbonization methods often face issues such as high energy consumption, severe pollution emissions, and low efficiency. In recent years, with the growing awareness of environmental protection and technological advancements, more advanced carbonization methods, such as biochar pyrolysis equipment, have emerged. These methods offer significant advantages in improving energy efficiency and reducing emissions.

Modern Carbonizer Machine – Advantages

- Eco-friendly with no pollution: Equipped with a gas dedusting system that efficiently removes harmful smoke and minimizes emissions.

- Continuous production: The carbonization machine is designed for large-scale, continuous operation, significantly improving output.

- Easy operation: The PLC control system allows operators to easily start, monitor, and adjust carbonizing machine through an interface, obviously reducing operational complexity.

- Safety assurance: Features include a micro-negative pressure system, explosion-proof holes, an alarm device, and explosion-proof water seals, ensuring secure operation.

- Energy-saving: Carboniser machine adopts double-return heating, syngas recycling, and high-temperature flue gas recovery technologies to maximize thermal efficiency.

Traditional Kiln – Disadvantages

- Severe pollution: Clay kiln carbonization produces a large amount of smoke with high concentrations, leading to significant air pollution.

- Long cycle and low efficiency: Traditional carbonization methods are suitable for small-scale, batch production.

- Labor-intensive and high technical demands: Skilled manual operation is required, and improper handling often leads to uneven carbonization or even complete charcoal loss.

- Safety risks: Traditional kilns typically rely on open flames for heating, which creates unstable conditions and makes the process highly prone to accidents.

- Low thermal efficiency: Temperature regulation in traditional kilns is highly imprecise, resulting in uneven heating throughout the process. This not only wastes energy but also prolongs the production cycle.

Role of Biomass Carbonization Machine in Sustainable Development

Waste Resource Utilization and Reduction

Carbonization machine converts organic waste (such as straw, wood chips, bamboo chips, coconut shells, etc.) into biochar and reusable gases through a high-temperature pyrolysis process. This transformation turns waste into valuable resources, effectively reducing waste accumulation and landfilling, thus contributing to environmental pollution control.

Greenhouse Gas Emission Reduction

During the carbonization process, organic materials in the waste are transformed into stable biochar, which has a strong carbon sequestration ability and helps reduce carbon dioxide emissions in the atmosphere. Additionally, gases produced during carbonization (such as methane, ammonia, etc.) can be captured and converted into energy, further decreasing greenhouse gas emissions.

Promoting Green Economy

As a representative of environmental protection technology, carbonization technology plays a significant role in advancing green industries. By effectively utilizing agricultural waste, wood residues, and other materials, carbonizer machine provides new growth opportunities for the green economy, fostering a win-win situation for both the economy and the environment.

Beston Carbonization Equipment Exported to the World

Beston Group is a leading manufacturer of biomass carbonization machine with a global presence. So far, Beston Group has completed numerous successful projects in many countries around the world. These projects have been instrumental in promoting sustainable waste management practices and reducing greenhouse gas emissions. Let’s take a look at some of carbonization machine projects.

Partner with Beston Group for Sustainable Development

Carbonization machine transforms waste biomass into high-quality biochar/charcoal, reducing carbon emissions while supporting a circular economy. Partnering with Beston Group enables you to capture this opportunity. This collaboration not only boosts profits but also drives sustainability. If you have any questions, please feel free to contact us. Our dedicated project managers will provide solutions customized to your specific needs. Follow us on LinkedIn for more updates!