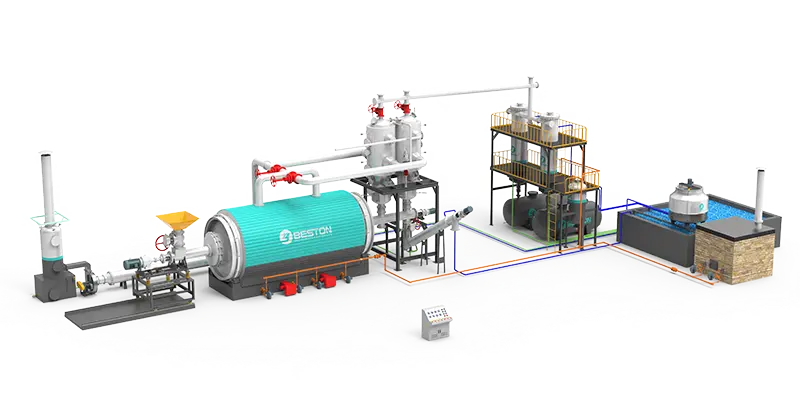

Integrated with decanter centrifuge + thermal washing + pyrolysis technology, thermal desorption unit effectively converts oil-contaminated soil and sludge with complex compositions into usable fuel oil. After processing, the remediated soil and sludge can be safely reused or returned to the site, fully meeting governmental environmental standards. This approach not only ensures clean and efficient recycling but also maximizes resource recovery, promoting both profitability and environmental sustainability. Read on to explore TDU – an environmental remediation solution for contaminated soil and sludge.

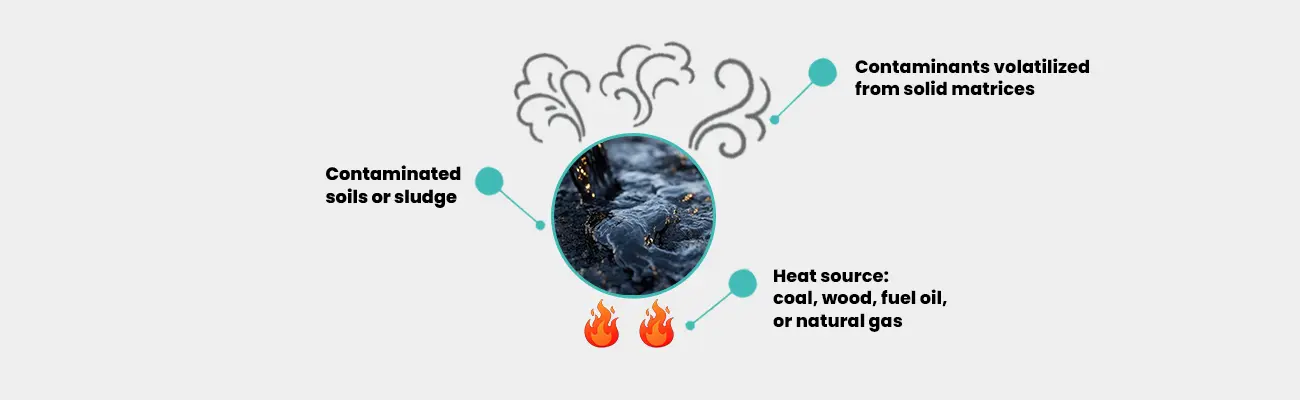

What is Thermal Desorption?

Thermal desorption technology is a term applied to treat many different types of soils or sludge contaminated with hazardous waste.

- Process principle: It is a physical treatment process that applies high temperatures to volatilize contaminants, removing or separating them from solid matrices (typically soil or oil sludge) for subsequent collection and treatment.

- Heating temperature: Heating at 90-320°C is considered low-temperature desorption (LTTD), while 320-560°C is high-temperature desorption (HTTD).

- Scope of Application: This technology is particularly suitable for treating materials excavated from refineries or sites contaminated by hydrocarbon leaks.

Market Available Thermal Desorption Unit: Definition & Classification

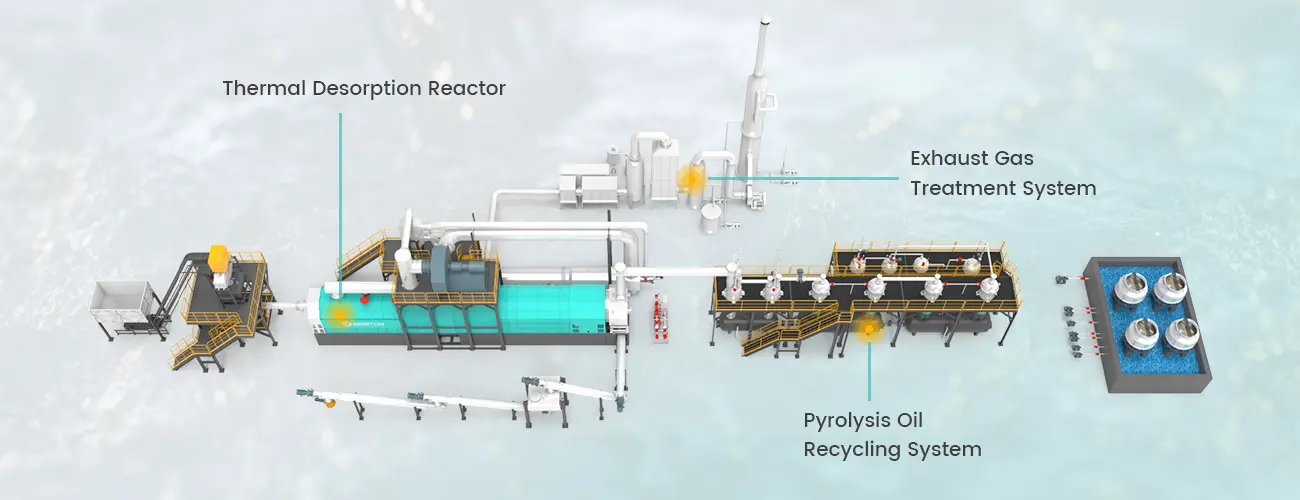

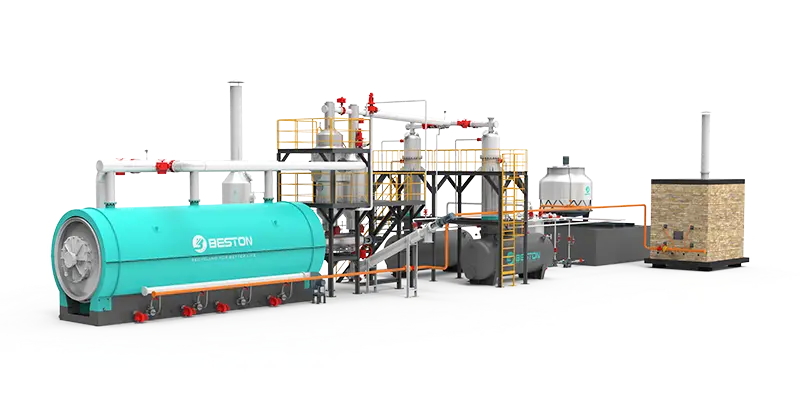

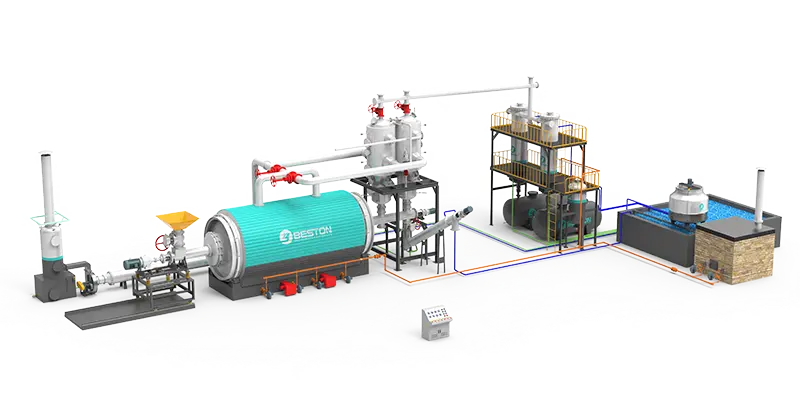

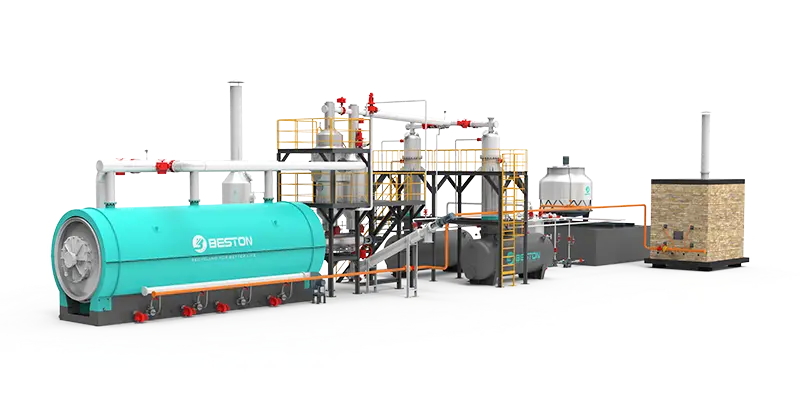

A complete tdu unit system generally consists of two main components: a reactor that applies thermal desorption technology and an off-gas treatment system. The reactor heats contaminated materials to separate hydrocarbons from solid matrices, while the off-gas treatment unit processes vaporized compounds for further recycling(fuel oil) or safe discharge(sand & solid residue). According to the type of the equipment existing on the market and the location of installation, TDU can be classified as follows:

Thermal Desorption Unit Types

- Direct heating unit: The material is directly exposed to the heat source or combustion gases, allowing rapid heat transfer and shorter processing time. This configuration is applicable to both low- and high-temperature desorption processes.

- Indirect heating unit: Heat is transferred through the cylinder wall, preventing direct contact with combustion gases and minimizing secondary pollution. It is suitable for operations under both LTTD and HTTD conditions.

Treatment Location Difference

- In-situ treatment: Thermal desorption occurs directly at the contaminated site without excavation, reducing material handling and potential exposure risks. This approach typically employs thermal blanket or thermal well technologies to treat localized contamination efficiently.

- Ex-situ treatment: Contaminated materials are excavated and processed in a controlled facility, allowing more precise temperature control and recovery efficiency. It is suitable for large-scale remediation projects requiring precise process control.

Beston Group’s TDU adopts indirectly heated, ex-situ treatment process, suitable for LTTD & HTTD.

Practical Application of Thermal Desorption Technology in Oman’s Oil Sludge Treatment Project

Elite International, an Omani company, focuses on oil sludge treatment. As environmental regulations tighten, traditional low-cost disposal methods no longer meet compliance standards. To avoid penalties and improve its corporate image, the company is adopting thermal desorption treatment solutions. Currently, the project has become a regional benchmark, promoting sustainable waste management and offering a cutting-edge and environmental friendly solution for oil sludge treatment in Oman.

Project Information

- Project start date: May 21, 2023

- Successful operation date: December 10, 2024

- Project duration: 570 days

- Project configuration: 2 sets of BLJ-16 TDU units, 1 set of BLJ-3.

- Raw material: Various types of oil sludge, including landing oil sludge and tank bottom sludge.

Project Status

Since its successful operation on December 10, 2024, the project has been running stably.

- Daily processing capacity: 30 – 35 tons of oil sludge per batch

- Oil yield: approximately 30%

- Annual processing capacity: up to 105,000 tons

Beston Group Held Oil Sludge Treatment Industry Exchange Conference at Elite International’s Project Site

On June 25 and 26, 2025, oil sludge treatment industry leaders and Omani government officials gathered Oman to attend the Oil Sludge Treatment Industry Middle East Exchange Conference 2025. On the second day of the event, participants visited Elite International’s project site. The visit allowed clients to gain a clearer understanding of the equipment’s operation, processing efficiency, and practical application in oil sludge resource utilization.

Successful Cases Display of Beston Thermal Desorption Unit

Decanter Centrifuge + Thermal Washing + Pyrolysis Technology: Production Efficiency Increase 200% ⬆️

Beston Group has been dedicated to the design and optimization of thermal desorption unit for more than 10 years. In the latest upgrade, we integrated front-end treatment technologies: decanter centrifugation and thermal washing, combined with pyrolysis technology, achieving a 200% increase in overall efficiency. Continue reading to explore how this integrated system enhances performance.

Coking Blockage

Thermal Efficiency Improvement

Production Efficiency Increase

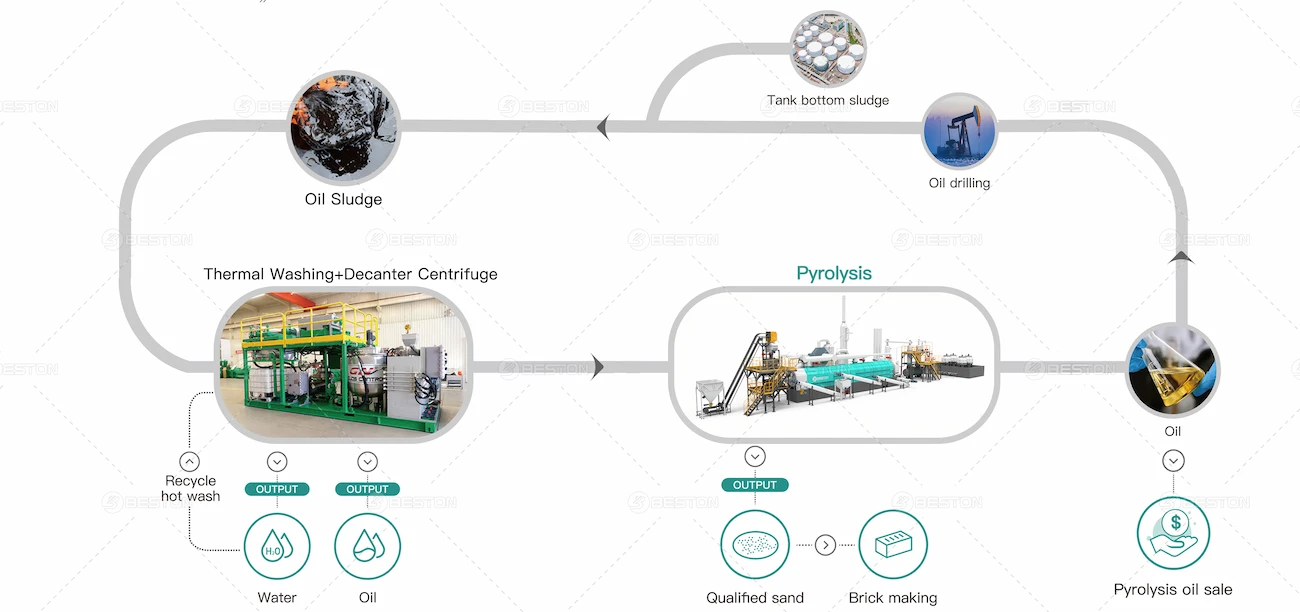

Decanter Centrifuge + Thermal Washing

As a critical pre-treatment step, decanter centrifuge + thermal washing can prepare the oil sludge for efficient pyrolysis. This process uses heat, emulsifiers and centrifugal force to separate oil, water, and solid particles. Through heating and stirring, the oil becomes more fluid, while water carries away fine particles and impurities. It effectively removes inorganic matter such as sand, salts, and metal particles, along with excess water. It brings key benefits to the pyrolysis process:

- Improves the purity of oil sludge;

- Increases oil yield;

- Reduces pyrolysis plant wear and extends service life.

Pyrolysis Technology

Pyrolysis (also known as thermal desorption) is a process in which polymerized hydrocarbons in oil sludge are thermally broken down and restructured under oxygen-free conditions. Thermal desorption equipment typically operates at 300–450 °C and continuously converts waste into valuable fuel oil, gas, and solid residues. Product composition varies depending on temperature and processing method. Key features of the pyrolysis process:

- Maximizes oil recovery from treated oil sludge;

- Minimizes secondary pollution with closed, oxygen-free design;

- Enables continuous and automated operation.

Technological Process Workflow of Thermal Desorption Unit

01Raw Material Feeding

Three feeding methods for different oil sludge liquid contents:

- Below liquid content 40%: belt conveyor

- 40%-60% liquid content: shaftless spiral

- More than 75% liquid content: sludge pump

02Oil Sludge Thermal Desorption

Thermal desorption reaction occurs in a high-temperature microaerobic reaction environment. During the reaction, oil sludge undergoes the following changes in thermal desorption plant:

- Under high temperature conditions, long-chain hydrocarbons in oil sludge are broken into small molecular hydrocarbons.

- Condensable components in the oil gas can be cooled through the condenser to form fuel oil.

- Non-condensable oil gas are purified by water sealing to form syngas, which provides energy for reactor.

03Oil Distillation(Optional)

Fuel oil is converted into higher-quality non-standard diesel through the oil distillation equipment. In this equipment, fuel oil goes through the following stages:

- Distillation: heating the fuel oil and separating components with different boiling points.

- Condensation: cooling and liquefying the evaporated components.

04Exhaust Gas Treatment

05Solid Residue Discharge

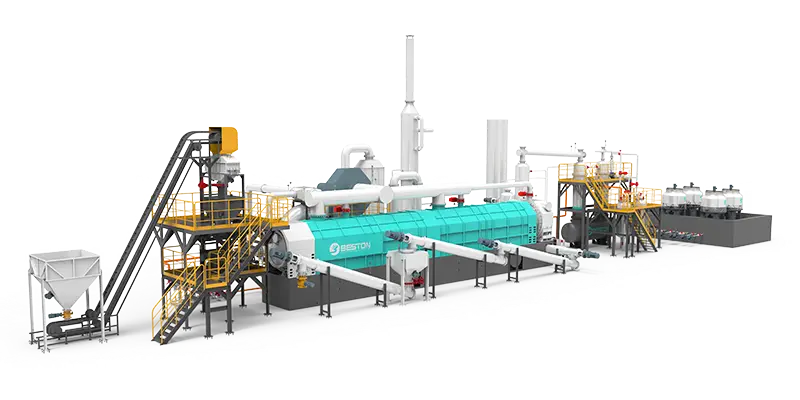

Models of Thermal Desorption Unit for Sale

Beston Group’s comprehensive product system provides customers with 3 types to choose from. They can meet the different production needs of customers. In addition, the diverse pyrolysis equipment options ensure that customers get the most suitable solution at a reasonable thermal desorption unit price.

Continuous Type: BLL-30

- Process 12,000 tons oil sludge annually

- 30 day continuous operation

- High automation: two operators required

- Policy support and incentives

- Easy to get environmental compliance and approval

Batch Type: BLJ-20 – Pyrolysis + Distillation Integrated Plant

- Process 7500 tons oil sludge annually

- Get naphtha & non-standard diesel in one step

- 1 batch/day

Batch Type: BLJ-16

- Process 6,000 tons oil sludge annually

- 1 batch/day

- 3 Configuration options

| Model | BLL-30 | BLJ-20 | BLJ-16 TDU | BLJ-16 Standard | BLJ-16 ULTRA |

|---|---|---|---|---|---|

| Manufacturer | BESTON | BESTON | BESTON | BESTON | BESTON |

| Time to Market | 2025 | 2025 | 2013 | 2013 | 2022 |

| Motor Brand | Chinese brand | Chinese brand | Chinese brand | Chinese brand | ABB Explosion-proof |

| Suitable Raw Materials | Waste plastics; Tires; Oil sludge | Waste plastics; Tires; Oil sludge | Oil sludge; Landing oil sludge; Drilling waste; Tank bottom oil sludge | Whole tire<120cm; Tire blocks<15cm; Oil soil with liquid content<30% | Waste plastics; Tires; Oil sludge |

| Input Capacity (Max.) | Waste plastic pellets: 0.8-1.05t/h Rubber powder: 1.25-1.5t/h Oil sludge:1.8-2.3t/h | Waste plastic pellets: 12-13t/d Tire: 18-20t/d Oil sludge: 20-25t/d | 16-18t/batch | Whole tire <120cm or Tire blocks<15cm: 10-12t/batch Sidewall removed tire: 15-16t/batch Oil soil: 16-18t/batch | Waste plastic bales: 8-10t/batch Whole tire <120cm or Tire blocks<15cm: 10-12t/batch Sidewall removed tire: 15-16t/batch Oil sludge: 16-18t/batch |

| Working Method | Fully Continuous | Batch | Batch | Batch | Batch |

| Final Oil Quality | Pyrolysis oil Pyrolysis oil with wax or naphtha | Pyrolysis oil, Non-standard diesel and naphtha | Pyrolysis oil | Pyrolysis oil | Pyrolysis oil Pyrolysis oil with wax or naphtha |

| Reactor Material | 304/310S Stainless steel | Q345R Boiler steel and 304/316L/310S Stainless steel | 304 Stainless steel | Q345R Boiler steel | 304 Stainless steel |

| Reactor Life Span (Years) | 5-8 | Q345R Boiler steel 2-3 304/316L Stainless steel 5-8 310S Stainless steel 8-10 | 5-8 | 2-3 | 5-8 |

| Guarantee (Months) | 12 | 12 | 12 | 12 | 12 |

| Delivery Time (Calendar Days) | 60-90 | 60 | 60 | 45 | 90 |

| Land Space Required (L*W*H*m) | 70*20*10 | 40*13*8 | 33*13*8 | 33*13*8 | 33*26*8 |

| Packing | 20*6*3m in bulk+13*40HQ | 1*40FR+4*40HQ | 1*40FR+8*40HQ | 1*40FR+3*40HQ | 1*40FR+8*40HQ |

| Installation Period (Calendar Days) | 60-90 | 45 | 45 | 45 | 60 |

BLJ-20 TDU: Three Major Technical Upgrades!

One Step Get Naphtha & Non-standard Diesel

Adopts fraction distillation technology, BLJ-20 machine enables simultaneous pyrolysis and separation of oil products, yielding both naphtha and non-standard diesel. This innovation delivers:

- Higher added value of oil products;

- Elimination of additional distillation equipment investment;

- Dual-function operation with reduced energy consumption.

Expand 50% Processing Capacity

With a ø2800×10000 reactor design, the system boosts capacity by 50%, enabling annual treatment of 7,500 tons of oil sludge. This upgrade results in:

- Significantly increase throughput;

- Enhance project efficiency;

- Stronger returns on large-scale operations.

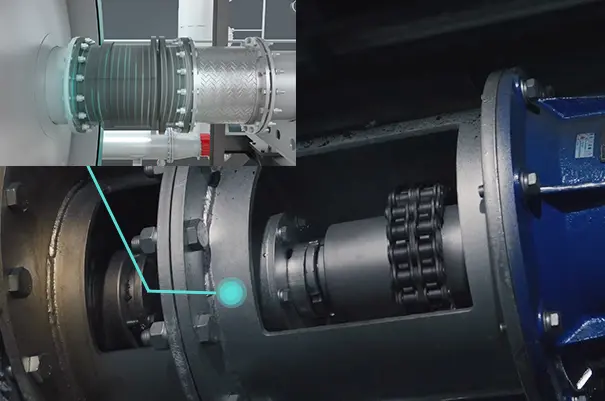

Enhance Safety Performance

By adopting thermal dynamic sealing and flexible high-temperature insulation technologies, the reactor achieves superior sealing compared to conventional pyrolysis systems. This provides:

- Significantly reduces thermal hazard risks;

- Zero oil-gas leakage or open flames on site;

- Substantial improvement in operational safety and comfort.

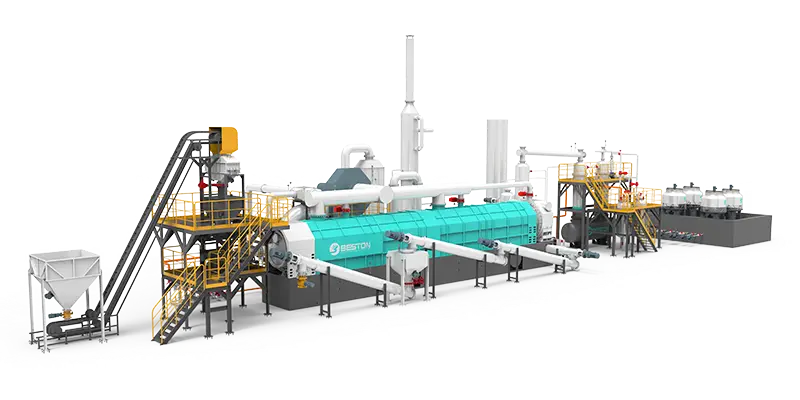

BLL-30 TDU: Provides Continuous and High-efficient Recycling Solution for Soil & Oil Sludge Contamination

Beston Group’s BLL-30 continuous thermal desorption unit has achieved significant performance enhancements through key technical breakthroughs. These upgrades enable investors to realize higher output, lower operational costs, and enhanced operational stability. These upgrades together demonstrate the effectiveness of the BLL-30 in addressing environmental challenges caused by soil/oil sludge contamination. Below are the key highlights of BLL-30:

12,000 Tons Oil Sludge/Yr

↓55% Fuel Use & ↓50% Emission

±10°C Precise Temperature Control

Government Policy Driven

12,000 Tons Oil Sludge/Yr

With an advanced oil-gas condensation system, tdu unit supports:

- 30 days non-stop machine operation

- Handling up to 12,000 tons of oil sludge per year

↓55% Fuel Use & ↓50% Emission

Reuses 80% of high-temperature exhaust and utilizes 20% for preheating the air supply, the plant supports:

- Fuel consumption is cut by 55%

- Emissions are reduced by 50%

- Meets EU environmental compliance

±10°C Precise Temperature Control

Adopt automated combustion and heat recirculation system, the machine can achieve:

- Keep reactor temperatures stable within ±10°C

- Ensure consistent pyrolysis effects when using different types of fuel

Government Policy Driven

- Government Bans: Many regions are banning batch systems.

- Policy Incentives: Low-emission systems qualify for subsidies, tax relief, and green financing.

- Faster Approval: Continuous systems ease EIA approval.

4 Technical Highlights of TDU Unit

High Combustion Efficiency

Full use of syngas: The entire system makes full use of the syngas generated in the reactor for secondary combustion. This reduces energy consumption. Combustible gas is purified by water seal to ensure clean combustion.

Anti-coking Design

- Friction-Assisted Self-Cleaning: Internal movement creates continuous friction between materials and components, helping to dislodge coke buildup during processing.

- Uniform and Controlled Heating: Thermal desorption unit maintains a stable temperature distribution to avoid localized overheating – one of the primary causes of coking.

Efficient Emission Control

- Waste gas emission: The waste gas generated by Beston equipment is processed by a high-end exhaust gas treatment system to meet EU emission standards. Moreover, if the emission standards in your area are higher, it is a good option for your project.

- Solid discharge: The discharging system is designed with water-cooled discharging method to reduce dust pollution. The discharging system is designed with water-cooled discharging method to reduce dust pollution. In addition, TDU can achieve continuous discharging without leaking oil gas.

Intelligent Control Mode

- PLC control: PLC and DCS(Distributed Control System) guarantee intelligent operation. They have high control efficiency. Therefore, this saves manpower and improves the working environment.

- IoT control: In addition, you can also choose an IoT real-time monitoring system. This system provides instant data insights, allowing for quick adjustments and improved efficiency. This facilitates customers’ overall operational control.

High-temperature Thermal Desorption Solution Meets Three Core Principles

Reduction

Significantly reduces the volume of oil sludge as well as the oil and water content in the residue.

Resource Utilization

Thermal desorption unit can recover high-quality fuel oil and syngas and improve energy efficiency through heat recovery.

Harmless Treatment

Wastewater and gas generated during operation can be recycled within the system, while the treated soil/sludge complies with national regulations and can be safely landfilled or reused.

Numbers Revealing Global Oil Sludge Treatment Crisis

With the rapid development of the petroleum industry, the accumulation of oil sludge has sharply increased per year. However, due to the lack of recycling solutions, oil sludge treatment still faces a big crisis. Here are data for your reference:

![]()

4.5 Billion

tons Oil Production per year

![]()

60 Million

tons Oil Sludge Production per year

![]()

5 Million

hectares of Oil-contaminated Soil

![]()

1 Billion

tons Oil Sludge Accumulation Existing

70%

Oil Sludge Can’t be Treated Properly

Classification and Components of Processable Oil Sludge

Oil sludge is generated during the extraction, gathering, transportation and refining process of oil. It is a mixture of mud, sand and water contaminated by organic matter such as crude oil. Unlike scrap tyre or waste plastic, this waste has a complex composition. It can be divided into various types based on its origin and composition. Each type has a different water, oil and solids content. According to the size of sludge particles, it can be divided into:

- Oil Sludge: Particle diameter <74 μm

- Oil-contaminated Sand: Particle diameter ≥74 μm

| Source | Type | Water Content % | Oil Content % | Solid Content % |

|---|---|---|---|---|

Drilling and Oil Extraction Drilling and Oil Extraction(Global share: 40%) |

Oil-based Cuttings | 8~15 | 15~25 | 60~80 |

| Waste Oil-based Mud | 40~50 | 10~20 | 30~40 | |

| Oil-contaminated Soil | 5~25 | 5~10 | 70~90 | |

Oil Gathering&Transportation Oil Gathering&Transportation(Global share: 15%) |

Tank Bottom Oil Sludge | 40-70 | 20-40 | 5-40 |

| Oil-contaminated Soil | 5~25 | 5~10 | 70~90 | |

Oil Refining Oil Refining(Global share: 30%) |

Oil-water Separator Sludge | 60~70 | 10~15 | 25~35 |

| Air Flotation Tank Sludge | 75~90 | 5~10 | 3~10 | |

| Activated Oil Sludge | 75~85 | <5 | 10~20 |

Profit Analysis of Oil Sludge Thermal Desorption Unit Project

Profit from Naphtha & Non-standard Diesel

The naphtha and non-standard diesel recycled from tdu unit has diversified applications that make recycled oil popular in the market. This gives it a wide range of sales channels. See the following uses:

- Naphtha & Naphtha from Non-condensable Gas: Chemical feedstock, fuel production, solvent use

- Non-standard Diesel: Industrial fuel, power generation, marine & construction machinery fuel

Profit from Solid Residue

The solid residues produced by tdu also generate incomes as long as placement properly:

- Sell to brick factory to make bricks;

- Sold to oil field companies for use as oil well anti-collapse agents.

Profits from Environmental Protection Disposal

Many companies need to handle waste sludge in compliance with regulations, but lack relevant equipment, so they will seek third-party services. Investors can provide oil sludge treatment services to this industries, charge environmental protection disposal fees, and form a long-term and stable profit model. The relevant industries are as follows:

- Oil extraction industry;

- Oil refining industry;

- Shipbuilding industry.

Subsidy from Government

Due to the significant hazards and serious pollution caused by oil sludge, government departments in various regions provide substantial financial support for oil sludge recycling projects. These subsidies include:

- Disposal fee subsidies: Enterprises receive government subsidies based on the volume of oil-contaminated soil or sludge successfully treated in compliance with regulations;

- Tax Benefits: Some governments encourage the production and use of pyrolysis oil through tax reduction policies;

- Green energy procurement policy: Governments or public institutions give priority to purchasing products and services using renewable fuels, which indirectly drives the thermal desorption system market.

TDU Unit Drives Petroleum Industry Transition

Closed-Loop Waste Utilization

Thermal desorption unit enables a closed-loop system where hazardous oil sludge is thermally treated and transformed into valuable byproducts such as fuel oil and non-toxic solids. This reduces landfill reliance and maximizes resource utilization, aligning with circular economy principles. By turning waste into revenue-generating outputs, petroleum operators improve both environmental and financial performance.

Process Optimization Across the Value Chain

From upstream drilling sites to downstream refineries, the equipment integrates seamlessly into multiple stages of the petroleum value chain. Its energy-efficient operation supports integration into existing facilities, helping reduce overall transportation demands and streamline oil sludge management processes across various stages of production.

Proactive Environmental Risk Control

Oil sludge contains hazardous hydrocarbons and heavy metals that pose serious compliance risks. TDU minimizes environmental liability by reducing the toxicity and volume of waste. This proactive risk control supports ESG commitments, helps meet regulatory requirements, and enhances long-term operational resilience.

TDU Unit Alleviates Ecological Burden

Oil sludge contains 5-50 of petroleum, polycyclic aromatic hydrocarbons (PAHs), dioxins, and radionuclides, heavy metals etc. So, it is toxic and flammable. Oil sludge pollutes the soil, water, and air resources that causing serious harm to the ecological environment and even human health. Currently, oil sludge is classified as hazardous waste. Its disposal is regulated by environmental protection agencies worldwide. Thermal desorption unit can reduce the ecological burden in the following aspects:

Reduce Soil Hazards

Thermal desorption system reduces the amount of harmful components that penetrate into the soil. Thus, problems such as soil degradation and surface vegetation destruction are solved.

Mitigate Water Hazards

Thermal desorption recovery prevents harmful substances from entering water resources. This optimizes water quality and the growth environment of aquatic organisms.

Eliminate Air Hazards

Oil sludge stored in the open air is flammable when exposed to fire. Thermal desorption recovery reduces the risk of release of sulfur-containing gases from burning.

Alleviate Hazards to Human Body

TDU decomposes toxic volatile compounds, minimizing inhalation risks of carcinogenic substances and preventing respiratory system damage.

Four Major Forces to Accelerate Transformation of Thermal Desorption

Across oil refining, petrochemical, and oilfield operations, oil sludge has long been a persistent environmental burden. Today, as the world accelerates the shift toward cleaner industrial practices and a circular economy, thermal desorption equipment is taking center stage in oil sludge treatment. Four major forces are accelerating the transformation of this sector:

Stricter Environmental Regulations

Governments are stepping up enforcement through comprehensive environmental policies to prevent improper handling of petroleum waste. Key policies include:

- China’s Technical Policy for Hazardous Waste Pollution Prevention and Control

- The EU’s Waste Framework Directive

- The U.S. EPA’s Resource Conservation and Recovery Act (RCRA)

Technology Advancement in Resource Recovery

Oil sludge contains recoverable oil, organic matter, and minerals. Tdu unit makes it possible to recover resources at scale. This not only maximizes material reuse but also supports the broader shift toward a circular economy, reducing both waste volumes and treatment costs.

Corporate Commitments to Sustainability

Sustainability is now central to corporate strategy in the oil and gas sector. Oil sludge treatment is no longer just a compliance issue—it’s a reflection of environmental responsibility. Companies are increasingly adopting clean, low-emission technologies to improve ESG performance, strengthen brand value, and meet stakeholder expectations.

Oilfields and Refineries Need

Oil sludge accumulation threatens safe and efficient operations, particularly in aging facilities. Treatment technologies that reduce volume and recover value are becoming essential to maintain productivity and reduce environmental risks. Upgrading sludge treatment capabilities has become a strategic priority for long-term facility sustainability.

EPC Service for Complete Thermal Desorption Project Delivery

Beston Group provides a complete EPC execution model for thermal desorption projects, covering the full project lifecycle—from engineering design and equipment manufacturing to on-site construction and operational delivery. This turnkey approach minimizes coordination efforts for clients and ensures efficient, compliant, and reliable project implementation.

Engineering

–Site Planning and Process Design

- Services: Site assessment, contamination analysis, process selection (high- or low-temperature), equipment layout, and emission control planning.

- Objective: Achieve effective treatment, meet regulatory standards, and optimize energy and investment efficiency.

Procurement

–Self-Manufacturing and Materials Supply

- Services: Manufacture core systems, including reactor units ect., and supply related structural, electrical, and insulation materials.

- Objective: Ensure quality consistency, and enhance system integration with controlled production and material supply.

Construction

–Installation & Commissioning Support

- Services: Civil construction, facility installation, pipeline and utility connection, commissioning, and performance testing.

- Objective: Enable smooth start-up, confirm treatment capacity and compliance, and provide training and technical support for long-term operation.

Get Customized Oil Sludge Treatment Solution

Beston Group thermal desorption unit has become the optimal choice for contaminated soil and oil sludge treatment. Our innovative technology helps customers extract economic value from oil sludge. Furthermore, integrated solutions guide customers from A to Z on their path to sustainable development. Just contact us to get your free customized solution. Also, you can follow us on Linkedin for more oil sludge recycling information.