Jute stick charcoal making machine efficiently converts jute sticks into high-quality charcoal with pyroysis technology. Produced charcoal meets EBC standards, suitable for carbon removal, soil enhancement, or industrial use. The BST-50S model has passed Puro.earth vetting to support carbon removal projects. Designed for biomass waste reduction and resource recovery, this machine helps businesses reduce waste, lower emissions, and create value from agricultural residues.

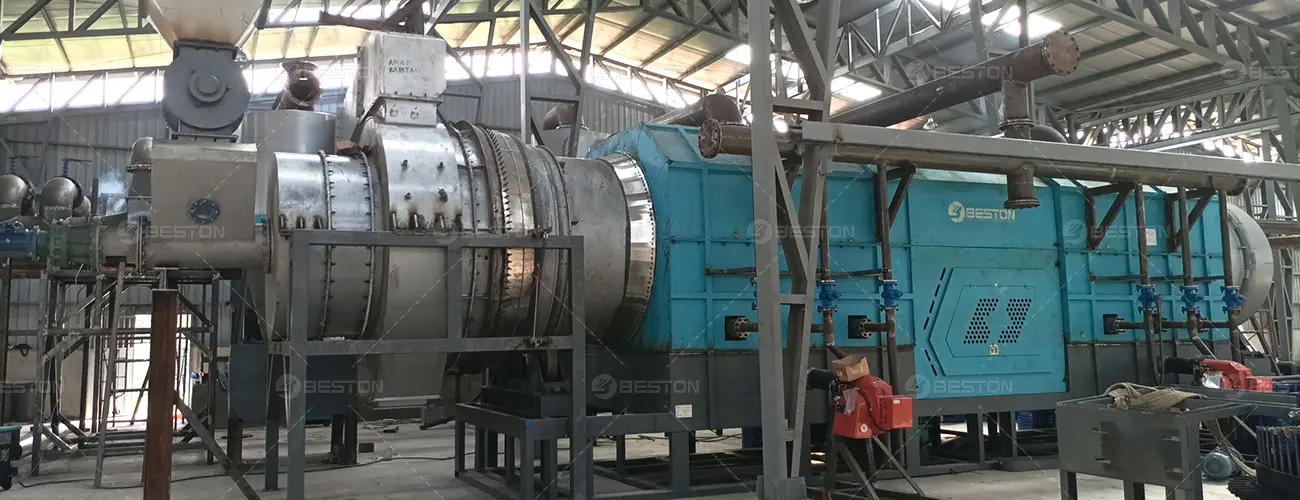

Beston Biochar Production Projects Across the Globe

2 Models of Jute Stick Charcoal Making Machine for Sale

Model BST-50

- BST-50S technology vetted by puro.earth

- 6,000 tons biochar production annually

- 7200H/Y stable and safe operation

- 4 Configuration options

Model BST-06

- 8000H/Y stable&safe operation

- Low-cost carbon removal process verification

- Small-scale test machine

- 2 Configuration options

| Model | BST-50 Standard | BST-50S LM | BST-50S HM | BST-50S MAX | BST-06 Standard | BST-06MAX |

|---|---|---|---|---|---|---|

| Time to Market | 2015 | 2022 | 2022 | 2022 | 2025 | 2025 |

| Operating Mode | Continuous | Continuous | Continuous | Continuous | Continuous | Continuous |

| Application | Commercial Scale | Commercial Scale | Commercial Scale | Commercial Scale | Testing | Testing |

| Dust Removal System | Standard | Advanced | Advanced | Advanced | Standard | Advanced |

| Feeding Capacity | 10-15m³/h | 10-15m³/h | 10-15m³/h | 10-15m³/h | 100-300KG/H | 100-300KG/H |

| Biochar Discharge Temperature | 45℃ | 45℃ | 45℃ | 45℃ | 45℃ | 45℃ |

| Puro.earth Authentication Model | × | √ | √ | √ | × | |

| Maximum Pyrolysis temperature | 650℃ | 650℃ | 650℃ | 850℃ | 650℃ | |

| Service Life | 5-8 years | 5-8 years | 5-8 years | 8-10 years | 5-8 years | |

| Annual Operating Time | 7200 hours | 7200 hours | 7200 hours | 7200 hours | 8000 hours | |

| Land Space Required (L*W*H*m) | 35m×15m×8m | 65m×15m×8m | 65m×15m×8m | 65m×15m×8m | 25m*18m*6m | |

| Total Power (KW) | 201.25kW | 453.35kW | 505.35kW | 505.35kW | 129.79 | 162.79 |

| Cooling Method | Recycling cooling Water | Industrial chiller | Industrial chiller | Industrial chiller | Recycling cooling Water | Industrial chiller |

| Installation Period (Calendar Days) | 50 | 70 | 70 | 70 | 45 | 50 |

BST-50S Jute Stick Charcoal Machine Vetted by Puro.earth for Carbon Removal

EBC Standard Biochar Production

BST-50S biochar machine annually produces 6,000 tons of jute stick biochar that meets the European Biochar Certificate (EBC) standard. The 6000 tons of biochar sequester 12000 tons of carbon per year. Compliance with the EBC standard ensures that customers can benefit from the diverse applications of jute stick biochar.

Qualification for CORCs

Through Puro.earth’s technical evaluation, the BST-50S jute stick charcoal making machine can help customers obtain CO2 Removal Certificates (CORCs). This means that customers’ efforts in reducing CO2 in the atmosphere meet strict technical standards.

Participation in Carbon Credit Trading

Obtaining CORCs allows customers to participate in the global carbon credit trading market. Customers can sell the CORCs they have earned, enhancing their return on investment. This sustainable income model is gaining popularity worldwide. (1 Ton Biochar ≈ 2-2.5 CDR Credit, 1 CDR Credit ≈ $150-250)

Diversified Application Scenarios of Jute Stick Charcoal

Carbon Removal

Soil Improvement

Building Material Production

Poultry & Livestock Breeding

Metal Smelting & Industry Production

Daily Heating & Cooking (BBQ)

Jute stick charcoal is also biochar. It makes outstanding contributions to reducing carbon footprint:

- Improves the soil’s carbon storage capacity by increasing organic carbon content.

- Reduce greenhouse gas emissions from the soil by reducing oxidation processes in the soil.

- Get carbon offset units/carbon credits by reducing carbon emissions.

- Earn revenue by trading carbon offset units/carbon credits on the carbon trading market.

In agricultural planting, jute stick charcoal has a soil improvement effect. Adding jute stick charcoal to the soil has the following benefits.

- Improve soil aeration and water permeability.

- Reduce soil acidification.

- Improve soil microbial activity.

- Reduce soil erosion.

Jute stick charcoal can be used to produce building materials such as cement additives, insulation boards, eco-friendly bricks, etc. These building materials have good properties:

- Insulation reduces energy consumption.

- Hygroscopicity reduces mold growth.

- Adsorption improves the indoor air environment.

In poultry and livestock breeding, jute stick charcoal is used as feed additives and shed litter. This has a positive impact on animal growth:

- Improve animal absorption of nutrients in feed.

- Regulate the intestinal flora balance of animals.

- Reduce methane emissions from cattle.

- Absorb odorous substances in sheds.

Metal Smelting:

- Good reduction performance improves smelting efficiency.

- Lower ash and sulfur content will not cause pollution to the metal smelting process.

Energy Supply for Industrial Production

- High calorific value provides a stable and reliable energy supply for industrial production.

- Low ash/sulfur content ensures environmentally friendly operation of industrial equipment.

Jute stick charcoal plays an important role in daily heating and cooking, especially as barbecue fuel. As a fuel, it has the following advantages:

- Good combustion characteristics ensure stable combustion for a long time.

- Burning smoke gives food a unique smoky flavor during the grilling process.

Understand Raw Material: Jute Stick

Main Components of Jute

Data for Jute Stick

Jute Sticks Recycling Difficulties

For jute cultivation, the stems are the most valuable part. The structure of the jute stem consists of bast (jute fibre) and core (jute stick):

- Jute Fibre: It is the most economically important segment in the processing of jute products. Thanks to its strong fibre structure, jute fibre is often used in textile production.

- Jute Stick: It is the main supporting part of the stem and contains more lignin. The harder texture and shorter fiber length make it less valuable for processing. Therefore, it is a waste product from the processing of jute products.

In the past ten years, the average annual global jute production has been approximately 3.5 million tons. According to statistics, jute sticks account for about 75% of jute cultivation. Therefore, approximately 2.6 million tons of jute sticks are produced globally every year. Asia is the main concentration area of global jute production. Among them, jute cultivation in India and Bangladesh accounts for 95% of global production. Therefore, these two countries are also the main sources of jute sticks.

| Top5 Countries of Global Jute Production | |

|---|---|

| Country | Production per Year |

| India | 1804.6Kt |

| Bangladesh | 1509.9Kt |

| Cambodia | 8.4Kt |

| China | 2.7Kt |

| Uzbekistan | 1.9Kt |

Lack of Technical Innovation

The fiber of jute sticks is tightly integrated with the woody parts. This makes the process of extracting fiber relatively complex. Therefore, traditional processing of fiber products is not suitable for jute sticks. Efficient technology to achieve large-scale recycling of jute sticks is a problem.

Low Market Demand

The resource value of jute stick is relatively low compared to jute fiber which is mainly used in textile manufacturing. Directly reusing jute sticks as fuel, fertilizer, and feed produces poor results. Therefore, jute stick recycling brings little economic benefit. This results in a lack of sufficient economic incentives for stakeholders.

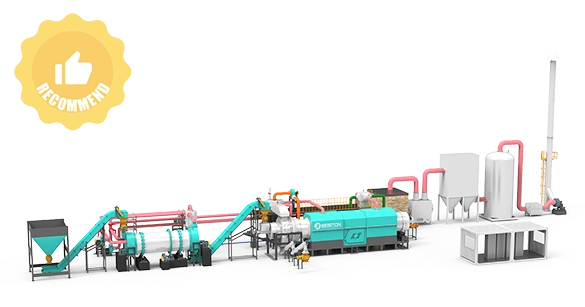

Working Process of Jute Stick Charcoal Making Machine

01 Jute Stick Pretreatment

For a biomass pyrolysis plant, the feed size should be less than 20 mm. The optimal feed size is 5-8 mm. Furthermore, the moisture content of jute sticks should be less than 15%. We provide dryers and crushers to bring jute sticks up to feeding standards.

02 Pyrolysis of Jute Stick

03 Combustible Gas Recycling

04 Charcoal Discharging

05 Exhaust Gas Treatment

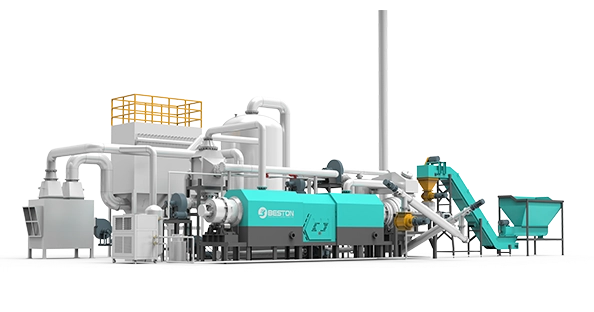

Key Features & Advantages of Jute Stick Charcoal Making Machine

Long-term Stable Operation

The tar and dust self-cleaning system prevents machine blockages, greatly reducing downtime and maintenance. It ensures continuous and stable operation throughout the year, fully meeting market demand for reliable long-term performance:

- BST-50S model – 7,000 hours/year of operation

- BST-06 model – 8,000 hours/year of operation

High-capacity Processing

The double-cylinder rotary reactor enables biomass to be dried in the inner cylinder, and then be spirally conveyed into the outer cylinder for carbonization. Compared with conventional designs, it achieves a larger processing capacity within the same footprint.

- BST-50 model — processing capacity of over 10 m³ per hour, ideal for large-scale projects.

Clean Emission Control

- Dust removal facilities are installed at the main parts where combustible gas and flue gas pass. This minimizes dust generation.

- The flue gas treatment system uses activated carbon and ceramic ring adsorption to ensure clean emissions.

Energy-efficient Reaction

- The combustible gas generated by the machine reaction serves as a heat source for the main furnace again. This reduces external fuel consumption.

- The reactor adopts a double-cylinder design. The inner cylinder is preheated for drying and the outer cylinder is heated. This improves thermal efficiency.

Safety Guaranteed Operation

- The biochar pyrolysis equipment adopts a multi-stage sealing structure. This ensures air tightness.

- The machine has multi-point settings for pressure and temperature detection feedback. An abnormality triggers the PLC alarm cabinet.

Smart Control Mode

- PLC intelligent control system realizes frequency conversion technology adjustment. This makes the machine run smarter.

- Internet of Things system (optional) enables remote machine operating parameter monitoring. This enables real-time feedback on the machine’s working status.

Sustainable Values of Jute Stick Charcoal Making Machine

Environmental Benefits

This solution supports SDG 13 (Climate Action) and SDG 15 (Life on Land) by reducing carbon emissions and protecting ecosystems.

- Lower deforestation: Eco-friendly biochar can replace some traditional wood charcoal.

- Carbon storage: High-temperature pyrolysis locks carbon in stable biochar, ensuring long-term removal.

Economic Value

This contributes to SDG 8 (Decent Work and Economic Growth), supporting sustainable and profitable business models.

The machine produces high-quality biochar that meets EBC standards, usable in agriculture, chemical, and energy sectors. With rising global demand for renewable energy and eco-friendly materials, it offers strong business opportunities.

Social Value

This aligns with SDG 1 (No Poverty) and SDG 11 (Sustainable Cities and Communities) by promoting green employment and equal opportunities.

Jute is widely cultivated in rural areas of Asia and Africa. The deployment of jute stick charcoal machine enhances the utilization of agricultural residues and creates local jobs. It increases farmers’ income, improves rural economic structures, and drives community development.

Beston Waste Biomass Recycling Projects Spread Globally

Jute stick charcoal making machine can also recycle other biomass, including waste wood, coconut shells, straw, rice husks, palm kernel shells, etc. Due to integrated recycling solutions and advanced machine technology, Beston Group has established long-term cooperation with customers around the world.

Start Recycling Project with Beston Group

As an effective way of waste management, the jute stick charcoal making machine plays an important role in the jute industry. If you intend to build your jute sticks to charcoal project, please contact us. Not limited to this, Beston Group provides various solid waste recycling solutions, including biomass, oil sludge, plastic, tyres, waste paper, etc. We look forward to being a solution provider for your recycling project. For more recycling information, please follow us on LinkedIn.