Continuous tyre pyrolysis plant can recycle 10,000 tons of waste tires annually with a 30-day non-stop operation model. It converts waste tires into valuable pyrolysis oil, carbon black, steel wire, and combustible gas. As demand for tire recycling grows and environmental regulations become stricter, continuous waste tire pyrolysis plants will gradually replace traditional batch-type systems. Choose Beston Group for reliable solutions!

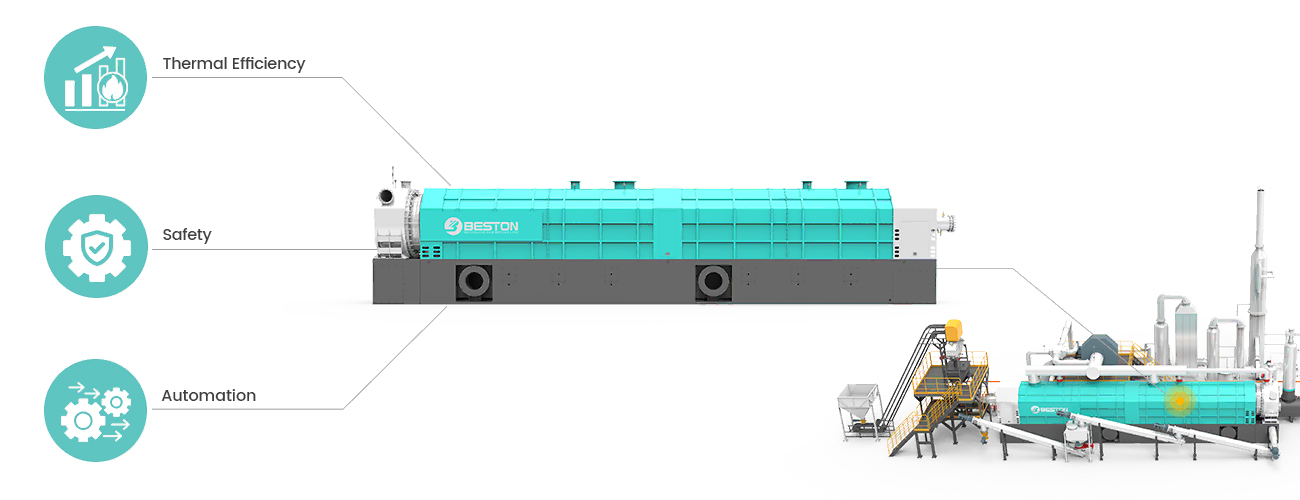

3 Technological Upgrades of BLL-30 Continuous Tyre Pyrolysis Plant

Oil Gas Anti-polymerization Condensation Technology

30 days continuous running

This technology utilizes spray direct mixing condensation to reduce the temperature of oil gas rapidly. Advantages:

- Improves the condensation efficiency.

- Prevents the secondary polymerization of olefin compounds and pipeline clogging.

- With 30-day continuous operation mode, BLL-30 handles 10,000 tons of waste tyres annually.

Hot Flue Gas Recirculation + Air Preheating Technology

↓ 55% fuel consumption & ↓ 50% emission

Hot Flue Gas Recirculation: About 80% of flue gas is redirected to the combustion zone and mixed with 1000–1300 °C hot air to heat the reactor.

Air Preheating Technology: The remaining 20% flows to a waste heat recovery unit to preheat combustion air.

Reactor Automatic Temperature Control Technology

±10℃ Precise Temperature Control

Equipped with multi-fuel automatic combustion system+ hot-air reuse system, the reactor maintains optimal thermal conditions across varying fuel types. Advantages:

- Keeps fluctuations within ±10°C to ensure stable and efficient operation.

- Increases pyrolysis oil yield and carbon black quality.

Parameters of Fully Continuous Tyre Pyrolysis Plant

| Model | BLL-30 |

|---|---|

| Manufacturer | BESTON |

| Time to Market | 2025 |

| Motor Brand | Chinese brand |

| Suitable Raw Materials | Waste plastics; Tires; Oil sludge |

| Input Capacity (Max.) | Waste plastic pellets: 0.8-1.05t/h Rubber powder: 1.25-1.5t/h Oil sludge:1.8-2.3t/h |

| Working Method | Fully Continuous |

| Final Oil Quality | Pyrolysis oil Pyrolysis oil with wax or naphtha |

| Reactor Material | 304/310S Stainless steel |

| Reactor Life Span (Years) | 5-8 |

| Guarantee (Months) | 12 |

| Delivery Time (Calendar Days) | 60-90 |

| Land Space Required (L*W*H*m) | 70*20*10 |

| Packing | 20*6*3m in bulk+13*40HQ |

| Installation Period (Calendar Days) | 60-90 |

Turning Point in Tyre Pyrolysis: From Batch to Continuous

Global demand for waste tyre recycling is growing rapidly. Compared with the traditional batch pyrolysis process, continuous tyre pyrolysis plant is gradually becoming dominant with higher efficiency, automation and environmental performance. Various driving forces are promoting the transformation of tire pyrolysis plant from “Batch” to “Continuous“. It is mainly reflected in the following aspects:

Expansion of Tyre Recycling Market

Recently, the global annual production of waste tires has reached 1 billion. This undoubtedly drives the rapid expansion of the recycling market. As a result, the traditional intermittent pyrolysis recycling method is difficult to meet the needs of large-scale recycling. Continuous waste tyre pyrolysis plant has higher processing efficiency and production capacity to help companies cope with the challenges of market expansion.

Emergence of Cutting-edge Technology

Industrial automation and intelligent technology have driven the progress of tire pyrolysis recycling. The equipment with continuous operation mode can be seamlessly connected with various automation equipment. Thus, this realizes automatic control and monitoring of the entire operation process. The introduction of these technologies not only reduces labor costs. Also, it improves production efficiency and controllability.

Promotion of Environmental Policies

Countries are paying more and more attention to the ecological impact of industrial production. As a result, the introduction of a series of environmental policies has made the emission standards of pyrolysis projects higher. Continuous equipment adopts more advanced exhaust gas treatment and pollution control systems. This can reduce harmful emissions and meet the requirements of environmental regulations.

Working Flow of Continuous Tyre Pyrolysis Plant

01 Feeding

- High-angle belt conveyor transports tyre particles to the sealed silo. In the silo, nitrogen protection system exhausts the excess air in tyre particles.

- Tyre particles in the sealed silo enters the weigh toometer for weighing through the first screw feeder.

- Weighed tyre particles enter the main furnace of continuous waste tire pyrolysis plant through the second screw feeder.

02 Tyre Pyrolysis

- Turn on the burner (fuel can be diesel, natural gas, LPG, etc.). The hot air generated by the burner enters the combustion chamber, thereby preheating the pyrolysis reactor.

- After the reactor heats up, the raw materials enter the main furnace for reaction. Under the action of high-temperature hot air, the molecular bonds of long-chain hydrocarbons in tyre particles are broken. As a result, they are decomposed into short-chain hydrocarbons, which exist in the form of oil gas.

- The hot flue gas after heat exchange with the reactor returns to the combustion chamber. Then, it mixes with the high-temperature hot air generated by the burner to provide heat, thereby improving thermal efficiency.

03 Pyrolysis Oil Collection

- High-temperature oil gas first enters the manifold system to separate heavy impurities. The heavy oil components fall into the residual oil tank under the action of gravity.

- The condensable components in the oil gas enter the condensation system. After passing through two condensers, the oil gas fully forms tyre pyrolysis oil under the action of cooling water. The oil enters the oil storage tank.

- The non-condensable components in the oil gas pass through the vacuum system and water seal to form syngas. Syngas enters the combustion system through the pipeline as fuel for the burner. Thus, it provides energy for the entire continuous tyre pyrolysis plant.

04 Waste Flue Gas Treatment

- Firstly, the waste flue gas after fully participating in the reaction enters the air-to-air heat exchanger. The air obtains heat from waste flue gas. Next, it enters the closed combustion chamber to provide oxygen for the burner.

- Waste flue gas then enters the air-water heat exchanger for further cooling.

- The cooled waste flue gas enters the chemical tower for desulfurization and denitrification.

- Subsequently, the waste flue gas enters the electrostatic precipitator and activated carbon dust collector for further purification.

- Finally, the treated waste flue gas which meets EU emission standards is discharged through the chimney.

05 Carbon Black Discharging

- First, the screw extractor at the end of the reactor discharges the carbon black. It enters the water-cooled carbon black storage tank.

- Then, the carbon black in the storage tank enters the water-cooled discharge system. Three screw extractors quickly reduce the temperature of the carbon black.

- Finally, a container is used to collect the finished carbon black.

Application of End Products of Continuous Tyre Pyrolysis Plant

Pyrolysis Oil

- Energy Supply: High calorific value tyre pyrolysis oil can be used as a fuel substitute in boilers, industrial furnaces, power plants, etc.;

- Power Generation: The non-standard diesel components obtained after distillation can be used for heavy oil generator sets to generate electricity.

Carbon Black

- Further Processing: Carbon black can be further processed to obtain higher quality rCB. This is a good filler for rubber products, especially tyre.

- Coatings: Carbon black is widely used in the coating and ink industries, such as automotive coatings, home appliance coatings, and printing inks.

Steel Wire

The steel wire separated after pyrolysis can be sold directly to steel mills. It is re-smelted as scrap steel material to obtain steel products.

Syngas

The continuous waste tyre pyrolysis plant can directly use syngas to provide energy for the continuous pyrolysis reactor. Thus, it achieves energy self-sufficiency.

Components of Continuous Tyre Pyrolysis Plant

The BLL-30 continuous tyre pyrolysis plant is composed of multiple integrated systems designed for efficiency:

- Feeding system

- Pyrolysis reactor system

- Hot air heating system

- Oil gas condensation system

- Discharging system

- Exhaust gas treatment system

- Control system

- Auxiliary system

The continuous tyre pyrolysis reactor provides a reaction environment for the pyrolysis of raw materials. The raw materials are thermally decomposed in the reactor to produce oil gas. As the core component, the reactor is designed with high-temperature resistant material, strict pressure control, and precise sealing design.

- 01 Tire Pre-treatment Line: It crushes waste tires into the optimal feed size (<15mm) to ensure full reaction in the pyrolysis reactor. It also removes steel wires, improving the purity of rubber powder. This helps BLL-30 continuous tire pyrolysis plant achieve 30-day non-stop operation.

- 02 Oil Distillation Equipment: It separates the components of tire pyrolysis oil based on their boiling point differences. After distillation, customers obtain non-standard diesel and gasoline with higher utilization value.

Technological Innovation of Continuous Tyre Pyrolysis Plant

Inert Gas Protection

Beston Group’s continuous waste tire pyrolysis plant uses inert gas (nitrogen) to replace the air in the feeding system. This not only maintains the oxygen-poor environment in the reactor, but also ensures the safety and stability of the pyrolysis process.

Precise Feeding with Real-time Monitoring

The machine uses a double screw conveyor and a high-precision weighing system. They control the continuity and accuracy of the feeding. In addition, this realizes real-time monitoring and stage statistics to ensure stable production.

Intelligent Control

Based on the PLC system and the Internet of Things technology, the fully continuous tyre pyrolysis plant realizes centralized system control and remote monitoring. This ensures the automation and intelligent management of the production process.

Triple Anti-coking

The fully automatic tyre pyrolysis plant integrates hot smoke recycling, catalyst anti-coking, and physical decoking technologies. They minimize coking on the inner wall of the reactor, ensuring production continuity and extending equipment life.

Sealed Discharging with Real-time Sampling

The discharge system adopts a high-temperature sealed design. This ensures continuous slag discharge while maintaining gas sealing. The sampling device monitors the state of pyrolysis residue in real-time to optimize pyrolysis parameters.

High-end Waste Gas Treatment

The system treats high-temperature waste gas through desulfurization and denitrification. It then removes dust with an electrostatic precipitator and activated carbon dust collector. This ensures that exhaust gas emissions meet EU environmental standards.

Global Cases of Beston Pyrolysis Project

Beston Group understands the critical role that exceptional customer service plays. From project initiation to completion, our dedicated project consultants and expert technical engineers are with you every step of the way. This commitment to service is why so many customers choose Beston Group for their pyrolysis recycling projects, such as tyre, plastic, oil sludge,etc. Below are some of our successful cases for your reference.

Complete Support for Efficient Continuous Tyre Pyrolysis Project Launch

Environmental Impact Assessment (EIA) Support

Purpose: The EIA ensures that the project complies with environmental regulations and minimizes its ecological footprint.

Key Areas of Support:

- Technical documentation offering

- Help communication with third-party EIA agencies

- Ensure final environmental compliance

Safety Assessment (SA) Support

Purpose: A robust safety assessment ensures the protection of workers, the public, and the environment during the operation of the continuous tyre pyrolysis plant.

Key Areas of Support:

- Technical documentation offering

- Health & Safety Training

- Ensure final safety compliance

Additional Implementation Support

Purpose: Provide end-to-end assistance throughout the lifecycle of the pyrolysis project, ensuring smooth execution from planning to operation.

Key Areas of Support:

- technical consultation and customized solution

- Site selection guidance

- Installation & commissioning support

- Training and Operations Manual

Join Beston Group – Your Partner in Sustainable Recycling!

As a leading manufacturer of continuous tyre pyrolysis plants, Beston Group is committed to offering top-tier pyrolysis recycling solutions and services to all customers. With the recycling industry growing rapidly and gaining global government policy support, now is the perfect time to invest. Want to learn more? Contact us today! You can also get more information on our Linkedin.