Straw charcoal machine is designed to convert straw to valuable biochar through pyrolysis. This machine provides a sustainable approach to agricultural waste treatment while creating added economic value. If you are facing challenges in handling large amounts of agricultural waste, welcome to explore how this equipment can provide an effective solution.

BST-50S Straw Charcoal Machine: Large-Scale Production and Long-Term Stability

Produce 6000 Tons Biochar Per Year

-Dual-cylinder Reactor Design

The double-cylinder core structure enables staged carbonization. The inner cylinder is used for pre-drying the material, while the outer cylinder ensures deep carbonization. This straw charcoal making machine design guarantees:

- Process capacity exceeding 10 m³ per hour

- Annual output of 6,000 tons of biochar

- Annual carbon sequestration capacity of 12,000 tons

Continuous Running for 7200 Hours Per Year

-Tar Dust Self-cleaning System

The tar and dust self-cleaning system is engineered to automatically remove sticky residues and fine particles from the pipelines during operation, preventing blockages throughout the process. This ensures:

- Stable and safe operation for 7,200 hours annually

- Extend service life of the equipment

- Reduce labor costs

BST-50S Straw Charcoal Making Machine Special Edition: Puro.earth Vetted Configuration

Benefits of Puro. earth Vetted BST-50S Model

Advantages of choosing us to start your project are as follows:

- Eligible to generate carbon credit and enter carbon trading;

- Comply with internationally recognized carbon reduction standards;

- Show proven positive environmental impact.

Puro. earth Vetted BST-50S Model Meets 7 Key Criteria

Puro’s evaluation of BST-50S biochar production equipment is built around the following 7 assessment criteria:

- Criteria 1: Methods to ensure complete combustion

- Criteria 2: Methods to ensure low emissions of air pollutants

- Criteria 3: Methods to ensure safe disposal of any waste stream

- Criteria 4: Emission testing of air pollutants

- Criteria 5: Emission testing of greenhouse gases

- Criteria 6: Testing of biochar quality

- Criteria 7: Material choices and expected equipment lifetime

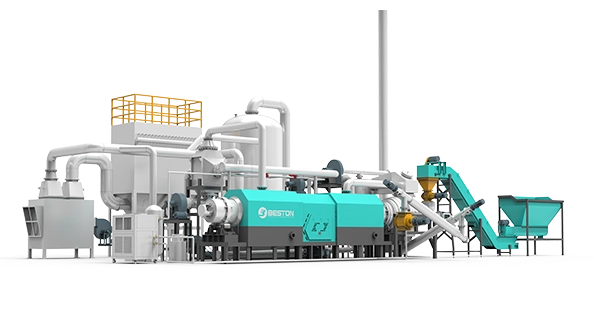

BST-50S Straw Charcoal Machine Applicable Configurations Vetted by Puro. earth

Configuration and meaning of components:

- Dryer (pre-dryer): for drying of the input biomass

- Pyrolysis system: rotary carbonization reactor

- Pyrolysis gas recovery system: pyrolysis gas combustion chamber, connected to the pyrolysis system (together forming the carbonization reactor)

- Cyclone de-duster: cyclone system to filter large particles from the syngas prior to its combustion

- Excess Pyrolysis Gas Combustion Chamber: a second combustion chamber where both excess syngas, alongside flue gas from the carbonization reactor, and primary air are combusted.

- High-end flue gas treatment system: flue gas cleaning system made of an air-to-air heat exchange, a pulse bag filter, a desulfurization tower, an activated carbon filter, and a chimney. It also includes devices for monitoring air pollutants and operating conditions.

- Heat exchanger and refrigeration systems: various components to cool down biochar and process water, or heat combustion air and syngas, at different stages of the process.

Parameters of Beston Straw Charcoal Making Machine for Sale

Beston Group, a supplier with extensive experience, offers 2 models for customers to choose from. Below are the detailed parameters for your reference.

Model BST-50

- BST-50S technology vetted by puro.earth

- 6,000 tons biochar production annually

- 7200H/Y stable&safe operation

- 4 Configuration options

Model BST-06

- 8000H/Y stable&safe operation

- Low-cost carbon removal process verification

- Small-scale test machine

- 2 Configuration options

| Model | BST-50 Standard | BST-50S LM | BST-50S HM | BST-50S MAX | BST-06 Standard | BST-06MAX |

|---|---|---|---|---|---|---|

| Time to Market | 2015 | 2022 | 2022 | 2022 | 2025 | 2025 |

| Operating Mode | Continuous | Continuous | Continuous | Continuous | Continuous | Continuous |

| Application | Commercial Scale | Commercial Scale | Commercial Scale | Commercial Scale | Testing | Testing |

| Dust Removal System | Standard | Advanced | Advanced | Advanced | Standard | Advanced |

| Feeding Capacity | 10-15m³/h | 10-15m³/h | 10-15m³/h | 10-15m³/h | 100-300KG/H | 100-300KG/H |

| Biochar Discharge Temperature | 45℃ | 45℃ | 45℃ | 45℃ | 45℃ | 45℃ |

| Puro.earth Authentication Model | × | √ | √ | √ | × | |

| Maximum Pyrolysis temperature | 650℃ | 650℃ | 650℃ | 850℃ | 650℃ | |

| Service Life | 5-8 years | 5-8 years | 5-8 years | 8-10 years | 5-8 years | |

| Annual Operating Time | 7200 hours | 7200 hours | 7200 hours | 7200 hours | 8000 hours | |

| Land Space Required (L*W*H*m) | 35m×15m×8m | 65m×15m×8m | 65m×15m×8m | 65m×15m×8m | 25m*18m*6m | |

| Total Power (KW) | 201.25kW | 453.35kW | 505.35kW | 505.35kW | 129.79 | 162.79 |

| Cooling Method | Recycling cooling Water | Industrial chiller | Industrial chiller | Industrial chiller | Recycling cooling Water | Industrial chiller |

| Installation Period (Calendar Days) | 50 | 70 | 70 | 70 | 45 | 50 |

Abundant Agricultural Straw: Wait for Proper Recycling Solution

Straw is an agricultural byproduct consisting of the dry stalks of cereal plants after the grain and chaff have been removed. It makes up about half of the yield by weight of cereal crops such as barley, oats, rice, rye, and wheat. If handled properly, it will present promising potential. If improperly handled, this agricultural waste leads to not only a waste of resources but also environmental risks. Therefore, it is meaningful to utilize a straw straw charcoal machine to recycle this biomass waste. Common straw waste includes:

- wheat straw

- barley straw

- oat straw

- rye straw

- buckwheat Straw

- corn stalks

- cotton straw

- alfalfa straw

- etc.

Straw Charcoal Making Machine: How Straw Are Recycled for Reuse

01 Pre-treatment System (Optional Configuration)

Before straw waste enters the reactor for pyrolysis, please ensure it meets specific feeding requirements (size 5-20mm, moisture below 15%). If not, you need auxiliary equipment such as dryers and crushers.

02 Feeding System

03 Pyrolysis System

- The biomass pyrolysis reaction typically takes 15 to 20 minutes, depending on specific raw materials.

- At temperatures ranging from 380°C to 450°C, the straw in the straw charcoal machine reactor decomposes into biochar while releasing significant amounts of syngas.

- Syngas will be recycled to provide heat for the heat.

04 Dedusting System

This system removes harmful substances from the exhaust gases. It includes cyclone dust removal, spray dedusting, activated carbon adsorption, etc.

Beston Group can customize the dedusting system based on your local environmental standards.

05 Cooling Discharging System

- The cooling system uses water-based heat exchange to lower the temperature of the biochar. Once cooled, the biochar is discharged from the reactor.

- This cooling process prevents biochar from spontaneous combustion when exposed to air and ensures that it is safe to handle and store.

06 Charcoal Briquetting System (Optional Configuration)

For further processing, a charcoal briquette machine can be added to straw charcoal making machine. This system compresses the biochar into uniform briquettes, which can be used as fuel or sold as a value-added product. The briquettes are easier to handle, store, and transport compared to loose biochar.

Benefits of Straw Pyrolysis to Biochar Solution

Investment on straw charcoal machine provides both economic and environmental advantages. It creates diverse revenue streams through biochar applications and addresses key environmental challenges related to agricultural waste. Detailed explanation as follows:

Wide Profitability: From Biochar Applications

Eco-friendly Benefits: From Agricultural Waste Reduction

Straw Biochar vs. Direct Field Return: Why Better to Sustainable Agriculture?

Long-Term Soil Health

Unlike straw, which decomposes quickly and only provides temporary benefits, biochar made from straw charcoal making machine stays in the soil for years. Its slow nutrient release system mimics the natural nutrient cycle, enhancing soil structure and fertility over time. This reduces reliance on chemical fertilizers and makes farming more sustainable. For farmers focused on long-term productivity, biochar is a more reliable and cost-effective choice.

Carbon Removal Effect

Straw biochar from biochar pyrolysis equipment helps combat climate change by locking carbon into the soil for extended periods. This prevents carbon from being released into the atmosphere as CO2. In contrast, straw decomposes rapidly, releasing carbon and contributing to greenhouse gas emissions. By using rice/wheat biochar, farmers also play a role in reducing global carbon emissions.

Soil pH Balance

Who May Need Straw Charcoal Making Machine?

Beston straw charcoal machine is ideal for investors and organizations that seek a sustainable and profitable solution for processing large quantities of straw. Potential investors may include:

Key Features to Look for in Beston Straw Charcoal Machine

Safe and Reliable Design

- Triple-seal design guarantees airtight operation, preventing leaks.

- Nitrogen replaces oxygen to prevent flash explosions in biochar reactor.

- Explosion-proof device safeguards against abnormal pressure.

Efficient Design

- Continuous pyrolysis technology for up to 720 hours of operation.

- Inner and outer cylinder structures of the reactor improve thermal efficiency

- Low-nitrogen combustion design improves combustion efficiency

Environmental Friendly Design

- Water-cooled slag discharging reduces dust generation

- Multi-channel dust removal device ensures flue gas cleanliness

- Excess syngas is burned to prevent environmental pollution

Smart Control Design

- PLC system controls the variable frequency fan for precise parameter adjustments.

- Key component failure triggers alarms through the PLC electrical cabinet.

- Optional IoT system of straw charcoal making machine enables real-time monitoring.

Straw Charcoal Machine Certifications: Proof of Reliability

As a manufacturer of straw charcoal making machine, Brston Group has achieved ISO 9001, ISO 14001, and CE recognition. These certifications ensure that our equipment is built to meet rigorous global standards for safety, quality, and environmental performance, providing customers with full confidence in their investment.

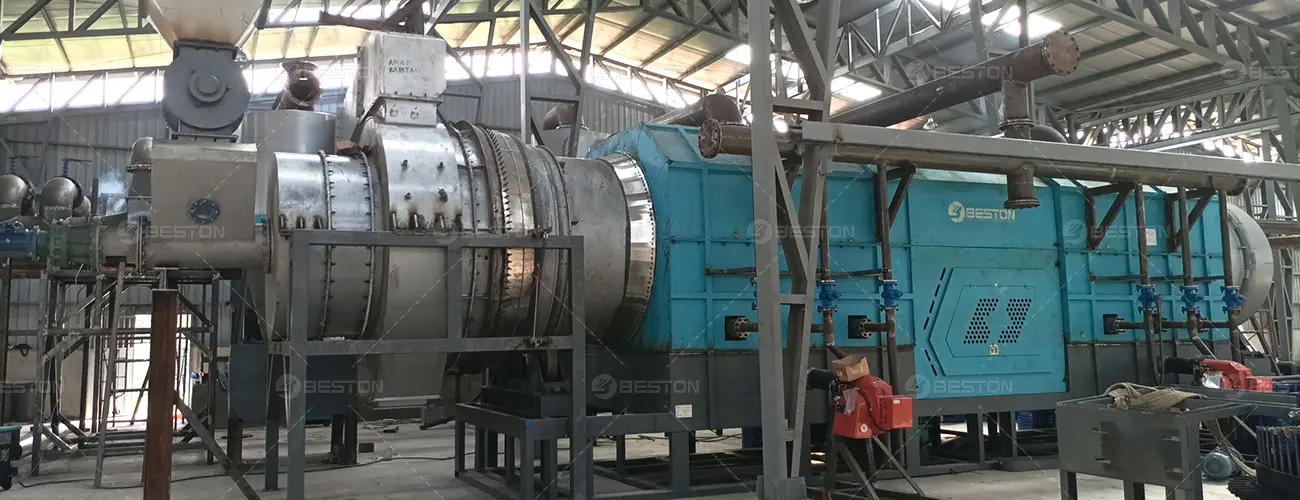

Global Cases on Straw Charcoal Making Machine

For decades, Beston Group has partnered with hundreds of customers worldwide, helping them unlock the potential of the biomass-to-biochar industry. Let a straw charcoal machine help you turn sustainable agriculture into a profitable reality.

Get Your Straw to Biochar Solution with Beston Group

As for agricultural waste management, straw charcoal machine provides a sustainable solution. Beyond reducing waste, it delivers the added benefit of producing valuable biochar. From your first question to successful operation, Beston Group provides full-cycle support to make straw charcoal technology work at its best for you. Contact us anytime with questions, and follow our latest updates on LinkedIn!