Pyrolysis plant cost is a key factor that customers must evaluate when investing in waste recycling projects. Beyond the machine price, overall costs include site setup, installation, and compliance. As a reliable pyrolysis plant supplier, we aim to offer cost-effective solutions. Read on to discover more about our equipment and what affects its final price.

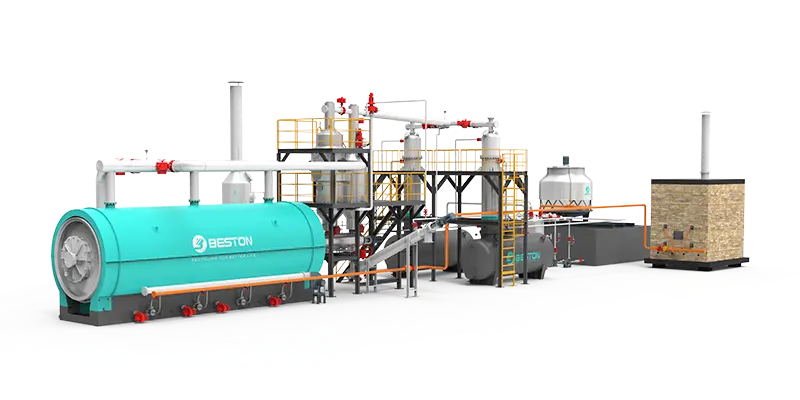

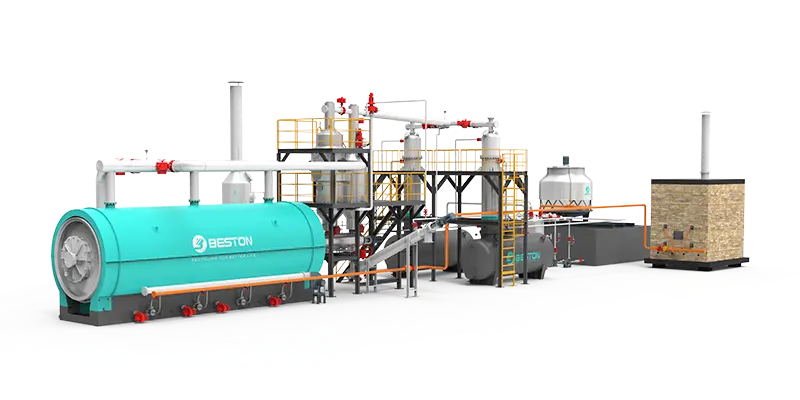

Pyrolysis Plant Cost Options from Beston Group

As an important component of pyrolysis plant price, the price of Beston Group equipment varies from different models and configurations:

- For batch type machine, the price starts at $67000;

- For fully continuous type machine, the price starts at $688900.

Customers can now choose the appropriate type based on their approximate budget and processing volume needs. Below are the parameters of different types of pyrolysis equipment for your reference.

Continuous Type: BLL-30

- Large-scale processing choice

- 30 day continuous operation

- High automation: 2 operators required

- Policy support and incentives

- Easy to get environmental compliance and approval

Batch Type: BLJ-20

- Large-capacity reactor (ø2800*10000)

- Get naphtha & non-standard diesel in one step

- 1 batch/day

Batch Type: BLJ-16

- Small processing choice

- 1 batch/day

- 5 Configuration options

| Model | BLL-30 | BLJ-20 | BLJ-16 Standard | BLJ-16 TDU | BLJ-16 WAX | BLJ-16 CAT | BLJ-16 ULTRA |

|---|---|---|---|---|---|---|---|

| Time to Market | 2025 | 2025 | 2013 | 2013 | 2022 | 2022 | 2022 |

| Motor Brand | Chinese brand | Chinese brand | Chinese brand | Chinese brand | Chinese brand | Chinese brand | ABB Explosion-proof |

| Suitable Raw Materials | Waste plastics; Tires; Oil sludge | Waste plastics; Tires; Oil sludge | Whole tire<120cm; Tire blocks<15cm; Oil soil with liquid content<30% | Oil sludge; Landing oil sludge; Drilling waste; Tank bottom oil sludge | Waste plastic bales (Max.0.9*0.9*1.6m) | Waste plastic bales (Max.0.9*0.9*1.6m) | Waste plastics; Tires; Oil sludge |

| Input Capacity (Max.) | Waste plastic pellets: 0.8-1.05t/h Rubber powder: 1.25-1.5t/h Oil sludge:1.8-2.3t/h | Waste plastic pellets: 12-13t/d Tire: 18-20t/d Oil sludge:20-25t/d | Whole tire <120cm or Tire blocks<15cm: 10-12t/batch Sidewall removed tire: 15-16t/batch Oil soil: 16-18t/batch | 16-18t/batch | 8-10t/batch | 8-10t/batch | Waste plastic bales: 8-10t/batch Whole tire <120cm or Tire blocks<15cm: 10-12t/batch Sidewall removed tire: 15-16t/batch Oil sludge: 16-18t/batch |

| Working Method | Fully Continuous | Batch | Batch | Batch | Batch | Batch | Batch |

| Final Oil Quality | Pyrolysis oil Pyrolysis oil with wax or naphtha | Pyrolysis oil, Non-standard diesel and naphtha | Pyrolysis oil | Pyrolysis oil | Pyrolysis oil with wax | Pyrolysis oil with naphtha | Pyrolysis oil Pyrolysis oil with wax or naphtha |

| Reactor Material | 304/310S Stainless steel | Q345R Boiler steel and 304/316L/310S Stainless steel | Q345R Boiler steel | 304 Stainless steel | 304 Stainless steel | 304 Stainless steel | 304 Stainless steel |

| Reactor Life Span (Years) | 5-8 | Q345R Boiler steel 2-3 304/316L Stainless steel 5-8 310S Stainless steel 8-10 | 2-3 | 5-8 | 5-8 | 5-8 | 5-8 |

| Guarantee (Months) | 12 | 12 | 12 | 12 | 12 | 12 | 12 |

| Delivery Time (Calendar Days) | 60-90 | 60 | 45 | 60 | 60 | 60 | 90 |

| Land Space Required (L*W*H*m) | 70*20*10 | 40*13*8 | 33*13*8 | 33*13*8 | 33*13*8 | 33*13*8 | 33*26*8 |

| Packing | 20*6*3m in bulk+13*40HQ | 1*40FR+4*40HQ | 1*40FR+3*40HQ | 1*40FR+3*40HQ | 1*40FR+3*40HQ | 1*40FR+3*40HQ+1*20GP | 1*40FR+8*40HQ |

| Installation Period (Calendar Days) | 60-90 | 45 | 45 | 45 | 45 | 45 | 60 |

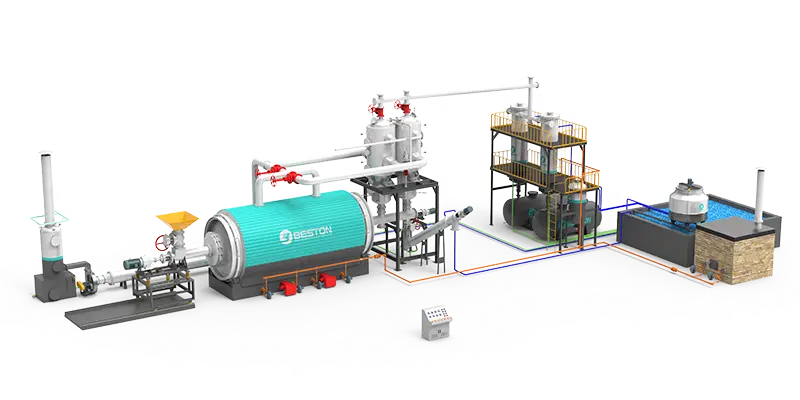

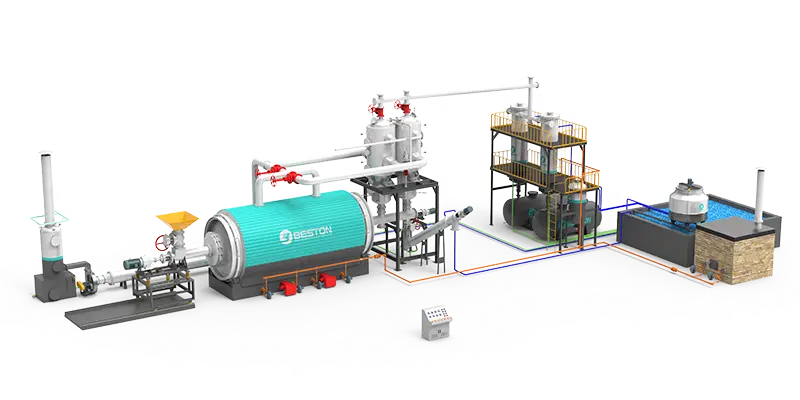

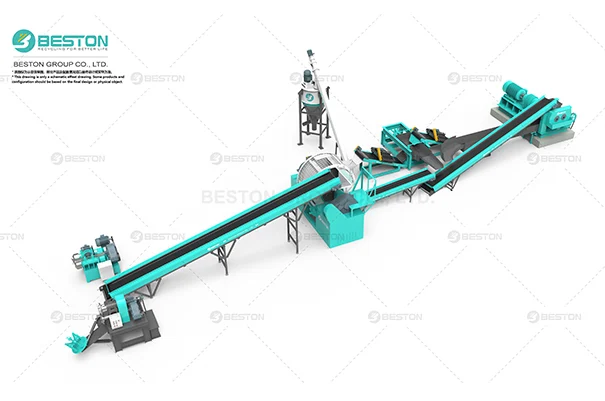

Technological Innovation of BLL-30 Continuous Pyrolysis Plant

After a series of technological upgrades, BLL-30 continuous pyrolysis plant demonstrates outstanding performance in continuous operation, energy efficiency, and precise automatic temperature control. The following are the corresponding technologies and their key outcomes.

Efficient Oil-Gas Condensation Technology

- Prevents secondary polymerization and clogging

- Ensures continuous operation for 30 days

- Improves oil recovery efficiency

Hot Flue Gas Reuse & Combustion Air Preheating

- Reduces fuel consumption by 55%

- Lowers exhaust gas emissions by 50%

- Reduces exhaust gas treatment investment

Automatic Temperature Control of Main Reactor

- Accurate temperature control within ±10°C

- Adapts to various fuel conditions

- Enhances automation and simplifies operation

3 Main Factors Affecting Pyrolysis Plant Cost

Factor 1: Operation Mode Decides Pyrolysis Machine Price

Continuous Mode: BLL-30

Batch Mode: BLJ-16 Series

Factor 2: Reactor Material Affects Pyrolysis Machine Cost

310S Stainless Steel

310S stainless steel can withstand high temperatures up to 1035℃ and has excellent anti-oxidation and acid corrosion resistance. Therefore, it is widely used in plastic pyrolysis plant. Although its cost is high, it can ensure safe operation under extreme conditions. In the long run, it reduces maintenance and replacement pyrolysis plant price.

304 Stainless Steel

304 stainless steel is suitable for high temperature environments of 600-700℃. It is often used in pyrolysis of oil sludge and tires. 304 stainless steel is more superior in high temperature anti-oxidation and corrosion resistance. It is a common material for pyrolysis reaction equipment, combining good performance and economy.

Q345R Steel

Q345R steel has a temperature resistance of about 450℃ and is suitable for pyrolysis processes at lower temperatures. Although it is cheap, it is prone to oxidation and corrosion under high temperature conditions. Its long-term use may result in higher maintenance costs. Therefore, this material is not suitable for high temperatures.

Factor 3: Configuration Options That Influence Pyrolysis Plant Cost

Different configuration options will also significantly affect the pyrolysis equipment cost. In addition to the main equipment, additional equipment can be selected to improve process performance or optimize operations. These optional equipment include:

Tire Shredder

For tire pyrolysis plant equipped with screw feeding, adding a shredder can reduce the feed size. This improves pyrolysis efficiency. In addition, steel wires in tires can be extracted in advance.

Distillation System

Further treatment of the pyrolysis oil produced during the pyrolysis process can extract high-value-added non-standard diesel and naphtha. This increases the economic value of the pyrolysis products.

Exhaust Gas Treatment System

This equipment is critical for project sites with higher emission standards. Exhaust gas treated by a high-end exhaust gas treatment system can meet EU emission standards.

Successful Case: Oil Sludge Pyrolysis Project in Hubei China

01 Problems & Needs

Business Limitation Due to EIA Restrictions: The Chinese customer (Hubei) focuses on oil sludge recycling but lacks EIA approval, limiting their access to coal tar business.

02 Action Solution

- Equipment Delivery: Supplied 4 sets of BLJ-16 thermal desorption units.

- EIA & SA Application Support: Provided full documentation and technical support to assist the customer in obtaining the Environmental Impact Assessment and Safety Assessment approvals.

03 Results Achieved

- Regulatory Compliance Achieved: Secured EIA and SA certifications with Beston’s full technical and documentation support.

- Stable Operations Ensured: Four BLJ-16 pyrolysis units process 12 tons of oil sludge per batch with a consistent 35% oil yield, demonstrating cost-efficiency aligned with the initial pyrolysis plant cost expectations.

- Business Expansion Realized: Client successfully launched coal tar processing and trading, generating strong economic returns.

Understand Running Cost of Pyrolysis Plant

Operating License Application

The operating costs of the plant first include the application fees for various licenses. An environmental, health and safety assessment must be completed. This ensures that the plant meets local regulatory standards. In addition, administrative procedures such as business licenses must be processed. These initial investments also involve a certain amount of capital investment.

Transportation & Installation of Equipment

The transportation and installation costs of the equipment are also one of the costs. Pyrolysis equipment is large and heavy, and the transportation process requires professional logistics services. In addition, the process of installing the equipment is complicated and requires a professional team to debug and install it. Therefor, it also further increases the pyrolysis plant cost.

Raw Material Procurement

The procurement cost of raw materials is an important part of the continued operation of the pyrolysis plant. The prices of raw materials such as plastics, waste tires, and oil sludge will fluctuate according to market conditions, which directly affects the production costs of the plant. The difficulty and conversion rate of different raw materials will also affect the overall production efficiency.

Operation & Maintenance of Equipment

In daily operations, the consumption of water, electricity, and gas is one of the main expenses in the high-energy pyrolysis process. At the same time, daily maintenance and regular inspection of the machine are essential. This avoids downtime caused by equipment failure. Therefore, hiring and training skilled operators is also a necessary long-term pyrolysis machine cost.

Maximize Your ROI with Reasonable Pyrolysis Plant Cost

Investing in a pyrolysis plant is not just about managing waste—it’s a strategic move to enhance profitability. While the pyrolysis machine price varies depending on design and capacity, the long-term returns often outweigh the initial investment due to multiple value-adding factors:

High-Value Products from Waste Conversion

Capable of processing plastics, rubber tires, and oily sludge, the plant delivers multiple marketable byproducts, which includes:

- Pyrolysis oil: Used as heating fuel or refined into non-standard diesel and naphtha, which have high market demand in the industrial energy sector.

- rCB: Reused in tyres, rubber manufacturing, ink production, and asphalt blending.

Automated Operation Reduces Labor Expenses

Equipped with a fully integrated PLC control system, the machine enables continuous monitoring and precise control of feeding, heating, and discharging processes. This high level of automation results in:

- Up to 80% reduction in labor staffing requirements

- Improved operational stability with fewer manual errors

Anti-Coking Design Reduces Maintenance Costs

The plant features an internal anti-coking structure that prevents material buildup on the reactor walls during continuous operation. This design improvement leads to:

- Reduced frequency of manual cleaning and deslagging

- Extended service life of the main reactor

- Lower maintenance costs and less unplanned downtime

Why Are Customers Satisfied with Beston Pyrolysis Machine Price?

Quality Guarantee

Beston Group ensures strict quality control throughout every stage of production. With advanced welding techniques and mature, continuously evolving manufacturing technology, each machine undergoes thorough testing before delivery. Reliable quality helps reduce unexpected failures, indirectly lowering pyrolysis plant cost in the long term. Customers are also welcome to visit our factory for on-site inspection.

Security Guarantee

In order to ensure the safety of the project, the equipment is equipped with a series of safety devices, such as explosion-proof devices, emergency exhaust valves, cracked gas-liquid seal anti-backfire devices, flame arresters, over-temperature & over-pressure alarm devices, and other safety devices. If you want a detailed list, please leave us a message.

Environmental protection

The combustion exhaust gas is processed by the de-dusting system and then discharged to meet the standards. And the excess combustible gas will also be burned through the exhaust chamber before being disposed of. If there are strict local environmental standards, Beston Group can provide a customized de-dusting system to meet the customer’s needs.

Considerate After-sale Service

Beston Group offers comprehensive after-sale support, including on-site installation guidance, operator training, follow-up visits, and 24/7 online assistance. Customers also enjoy repurchase discounts, helping reduce operational and maintenance costs, thus reducing long-term pyrolysis machine cost.

Get Your Exclusive Pyrolysis Plant Cost

Understanding the pyrolysis plant cost plays a crucial role in making an informed investment decision. If you’ve decided to move forward with this project, Beston Group is ready to support you with reliable solutions and comprehensive services. For more detailed information about the cost and configuration options, feel free to reach out with your questions. Leave us a message below, and we will get back to you as soon as possible. You can also explore more insights about pyrolysis plant cost on our LinkedIn.