In the global oil and gas exploration industry, oil-based mud (OBM) has become an indispensable component for ensuring operational success. However, its waste stream often poses severe environmental risks. Is it possible to turn this hazardous sludge back into a valuable asset? In this guide, we explore the essential role of OBM, the regulatory pressures of its disposal, and how advanced thermal desorption is redefining waste recovery in the modern oilfield.

1. What is Oil-based Mud?

1.1 Definition

Oil-based mud (OBM) is a high-performance drilling fluid where oil serves as the continuous phase. In the oil and gas industry, it is the preferred choice for complex drilling projects. Unlike water-based fluids, OBM offers superior thermal stability and lubrication, making it indispensable for drilling through reactive shale formations, high-temperature wells, and extended-reach horizontal wells – particularly in oil-rich regions like the Middle East, where challenging geological conditions are common.

1.2 Core Composition

OBM is essentially an invert emulsion consisting of oil as the external phase (70%–95% by volume) and water or brine as the dispersed internal phase. Key additives are used to fine-tune its performance:

- Weighting agents: Such as Barite, to control hydrostatic pressure.

- Emulsifiers: Typically fatty acids, to stabilize the oil-water mixture.

- Viscosifiers: Such as organophilic clays, to ensure proper hole cleaning and fluid suspension.

2. The Role of OBM in Drilling Operations

2.1

Cool and Lubricate the Drill Bit

One of the primary functions of oil-based mud (OBM) is to act as a high-performance lubricant for the drilling assembly. By significantly reducing friction between the drill bit and the rock formation, OBM minimizes mechanical wear and dissipates heat effectively. This superior lubrication extends the operational lifespan of expensive drilling tools, especially in high-torque environments like horizontal or extended-reach wells.

2.2

Effective Drill Cuttings Transport

OBM serves as a critical transport medium to carry drill cuttings from the bottom of the wellbore back to the surface. Its optimized rheological properties ensure that rock fragments are kept in suspension even when circulation is temporarily stopped. This prevents “cuttings beds” from forming, which could otherwise lead to pipe sticking and drilling delays.

2.3

Wellbore Stability and Formation Protection

OBM is essential for maintaining pressure control and structural integrity. By adjusting the mud density, OBM creates a stable hydrostatic pressure column that prevents wellbore collapse and blowouts. Furthermore, its non-aqueous nature creates a superior filter cake on the well wall, preventing fluid seepage into the formation.

3. Environmental Challenges in Managing OBM Waste

3.1 The Surge in OBM Waste Generation

As global energy demand drives drilling into deeper and more complex formations, the consumption of oil-based mud has increased significantly. This intensification leads to a massive volume of spent mud and oily drill cuttings. Managing these waste streams has become a critical logistical and operational challenge for oilfield operators, as traditional disposal methods can no longer keep pace with the scale of production.

3.2 Risks to Soil Quality and Agriculture

If handled improperly, the hydrocarbons, heavy metals, and chemical additives within OBM can leach into the surrounding earth. This contamination severely degrades soil fertility and alters its chemical composition, making it toxic to vegetation. Once these pollutants enter the soil, they can persist for decades, potentially entering the food chain and rendering vast areas of land unusable for agricultural or ecological purposes.

3.3 Impact on Water Resources and Ecosystems

One of the most urgent threats is the contamination of local water bodies and underground aquifers. Runoff from drilling sites can carry oily pollutants into rivers and lakes, devastating aquatic ecosystems and killing fish and wildlife. More importantly, if these toxins infiltrate groundwater, they pose a direct and severe risk to human health, contaminating the very sources used for drinking and irrigation.

4. Regulatory Framework and Waste Classification of Oil-based Mud

4.1 Compliance and Environmental Governance

While specific regulations vary by jurisdiction, international best practices often align with US EPA guidelines, while oil-rich regions like the Middle East are now implementing even more stringent ‘Zero Discharge’ mandates to protect their desert and marine ecosystems.

US EPA & RCRA

In the United States, OBM management is governed by 40 CFR Part 435, which sets strict limits on the toxicity and biodegradation of base oils. Under the Resource Conservation and Recovery Act (RCRA), any waste transported off-site must meet rigorous handling protocols.

Middle East standards (Aramco/ADNOC/KOC)

In regions like Saudi Arabia and the UAE, National Oil Companies (NOCs) enforce even stricter local mandates. For example, Saudi Aramco and ADNOC typically require a Zero Discharge policy, meaning no oily waste can be released into the environment without advanced thermal treatment.

International protocols

Operators worldwide increasingly adhere to the OSPAR (North Sea) standards, which serve as a global benchmark for protecting marine and terrestrial environments from hydrocarbon contamination.

4.2 Numerical Criteria for Oil-based Mud

OBM is classified as hazardous waste when it exceeds specific numerical thresholds. Meeting these standards is the primary driver for utilizing thermal desorption technology:

Total Petroleum Hydrocarbons (TPH)

In the Middle East and many EPA-regulated zones, the “Gold Standard” for treated solids is TPH < 1%. In sensitive ecological areas, this requirement can be as low as < 0.5%.

Toxicity (TCLP Limits)

Under EPA’s Toxicity Characteristic Leaching Procedure, waste is hazardous if it leaches heavy metals above specific levels, such as Lead > 5.0 mg/L or Benzene > 0.5 mg/L.

Ignitability

Due to the base oil content, OBM waste with a flash point below 60°C (140°F) is classified as ignitable, requiring specialized explosion-proof treatment equipment.

Oil on Cuttings (OOC)

International maritime and land-disposal laws often limit oil retention on cuttings to < 6.9% (by weight) before any form of discharge can even be considered.

5. Maximize Resource Recovery from OBM Waste via Thermal Desorption Technology

5.1 Thermal Desorption Technology Overview

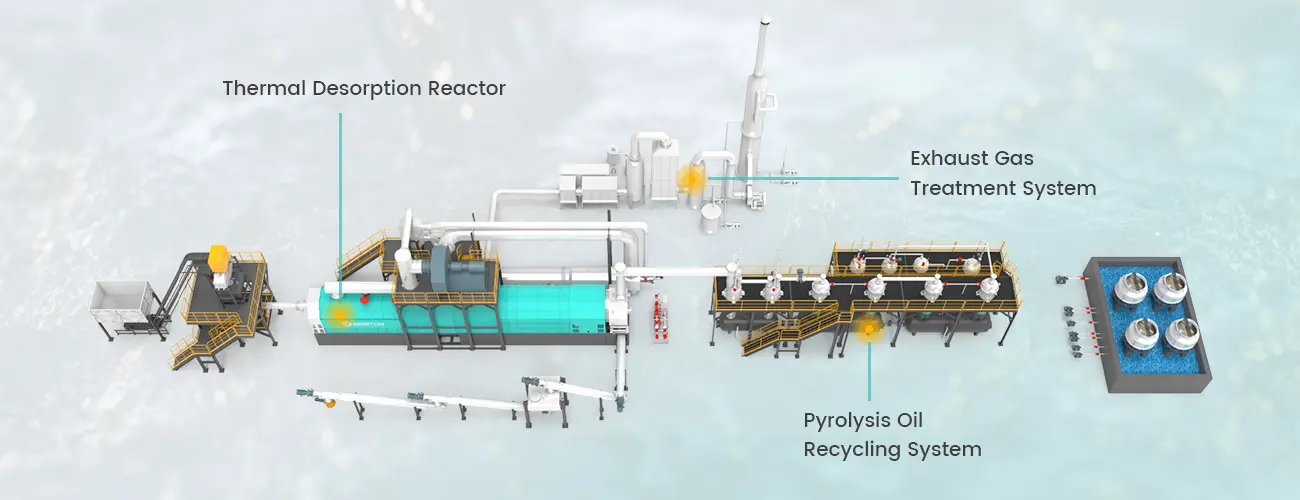

Thermal desorption technology is an effective solution for processing Oil-based mud (OBM) waste. In an oxygen-free environment, our thermal desorption unit applies high temperatures to break down the complex hydrocarbon chains within the sludge. This process thermally separates the oil from the mineral solids, converting hazardous waste into high-quality fuel oil and solid residue.

5.2 The Pyrolysis Process: From Sludge to Resource

The treatment of OBM waste follows the thermal process:

- Feeding & Heating: OBM waste is fed into a sealed pyrolysis plant where it is heated to specific temperatures (300°C to 450°C).

- Vaporization: The hydrocarbons (base oils) and water are vaporized, leaving behind dry, oil-free solids.

- Condensation: The gas phase passes through a cooling system, where it is condensed back into liquid form for collection and reuse.

5.3 High-Value Outputs and Energy Recovery

Our oil sludge pyrolysis equipment transforms hazardous OBM into three distinct, usable streams:

Pyrolysis Oil

A kind of industrial fuel and can be processed into high quality naphtha and non-standard diesel.

Solid Residue

Inert, hydrocarbon-free solid residue that meets environmental standards for safe landfill disposal or use in construction materials (e.g., brick making).

Non-condensable Gas

A small portion of gas can be recycled back into the system’s burners to provide a self-sustaining heat source, significantly reducing operational costs.

6. Conclusion

Properly managing OBM waste is a critical environmental and regulatory challenge. Beston Group’s advanced thermal desorption plant provides a high-efficiency solution, recovering valuable pyrolysis oil while ensuring total compliance. By transforming hazardous oil-based mud waste into reusable resources, we empower the oil and gas industry to achieve a sustainable, circular economy.