BBQ charcoal making machine is gaining popularity as a profitable investment, driven by the growing global demand for barbecue charcoal in outdoor grilling and cooking. To meet this market need, Beston Group offers advanced and efficient BBQ charcoal machine. The machine utilizes pyrolysis technology to convert biomass into high-quality BBQ charcoal. For more details, please read on.

BBQ Charcoal Making Machine Meets Puro.earth Vetting Standards

Beston Group’s BBQ charcoal machine (BST-50S Model) has successfully achieved Puro.earth’s technology vetting standards, marking a significant milestone in the commitment to sustainable and innovative carbon removal solutions. This successfully vetting confirms that our technology is effective in reducing carbon emissions and contributing to global climate goals.

Biochar Quality Testing Standards

In line with Puro.earth’s requirements, Beston’s biochar meets high-quality standards for carbon sequestration (H/Corg < 0.7). The biochar produced is stable, highly porous, and has long-term potential to store carbon in the soil, further aiding in the fight against climate change.

Air Pollution Standards

The charcoal production process in Beston biochar making machine complies with stringent air pollution standards, ensuring minimal emissions of harmful gases during the carbonization process. These advanced systems use high-efficiency dust removal technologies, reducing particulate matter and volatile organic compounds (VOCs) released into the atmosphere.

GHGs Emissions Standards

Beston’s BBQ charcoal making machine meet rigorous greenhouse gas (GHGs) emissions standards. Utilizing cutting-edge combustion technology, the machine can ensure complete combustion of pyrolysis gases, significantly reducing overall greenhouse gas emissions and helping to mitigate climate change. CH4 emissions are low, representing < 0.1% of the carbon stored in the biochar.

BST-50S: 6000 T Biochar Production & 12,000 T CO₂ Sequestration Annually

BST-50S BBQ charcoal machine is capable of producing 6,000 tons of biochar annually, which is equivalent to sequestering 12,000 tons of CO₂ each year. It provides a sustainable and innovative approach to carbon reduction. The following technologies make this achievement possible:

Tar Dust Self-Cleaning System

The tar dust self-cleaning system of BBQ charcoal making machine automatically removes coking and dust buildup generated during the pyrolysis process, enabling:

- 7,200 hours of continuous operation

- Uninterrupted material flow with minimal downtime

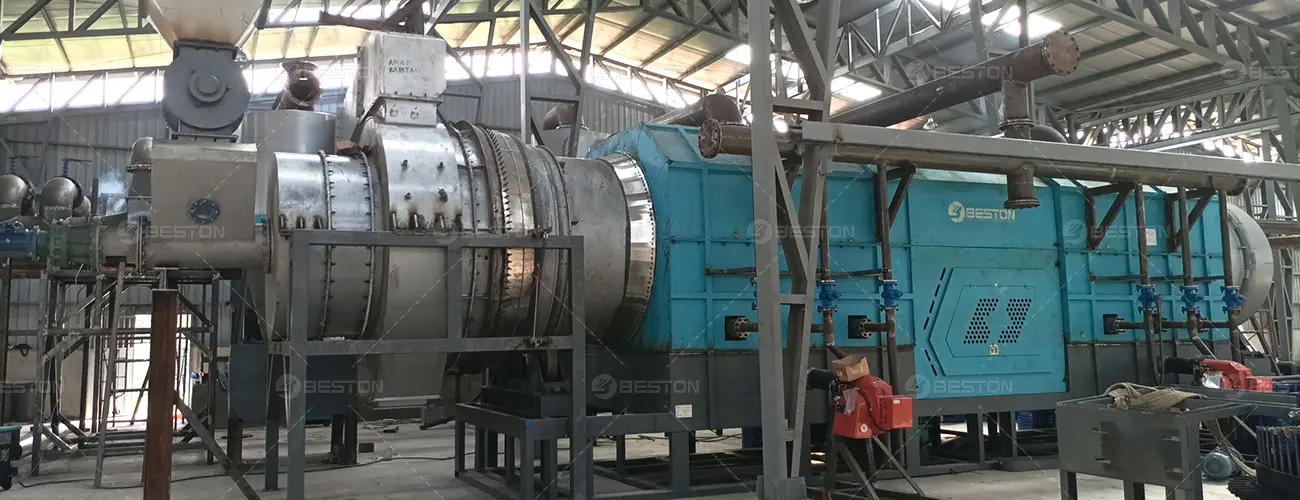

Dual-Barrel Rotary Reactor

The main reactor adopts a dual-barrel design that enables staged carbonization. The inner barrel is used for pre-drying, while the outer barrel for deep carbonization. This design ensures:

- Processing capacity of over 10 m³ per hour

- Enhanced quality and uniformity of the biochar

Popular BBQ Charcoal and Rising Market Demand

Rising Demand for BBQ Charcoal

The BBQ charcoal market value has surpassed US$ 3.2 billion in 2023. It is forecasted to drive a compound annual growth rate (CAGR) of 4.8% from 2023 to 2033. This growth trajectory could push the market value beyond USD 5.2 billion by 2033.

More and more popular outdoor cooking activities (barbecues, picnics, camping, etc) are driving this growth. Home cooking preferences for BBQ charcoal is another driver. Consequently, investors in this sector are likely to get good economic benefits.

Popular BBQ Charcoal Briquettes

This combination of benefits makes BBQ charcoal briquettes a popular choice for home cooks and grilling enthusiasts, fueling market growth worldwide.

- Flavor Infusion: The smoky flavor from BBQ charcoal adds depth to the taste of the food.

- Convenient to Use: BBQ charcoal is lightweight, portable, and readily available in various forms.

- Longer Cook Times: The high density of briquettes ensures extended cooking durations, perfect for longer gatherings without interruptions.

What Material to Choose to Make Charcoal?

Considering the cooking uses of barbecue charcoal, various types of biomass are excellent choices for BBQ charcoal making machine. They are from natural materials, cost-effective, and readily available. Charcoal made from these biomasses can impart a subtle, delightful flavor to food, a desirable trait for BBQ enthusiasts. Specific raw materials like:

- Wood: including logs, branches, leaves, sawdust, etc.;

- Straw: including wheat straw, rice straw, corn straw, and other crop straw;

- Nutshells: including peanut shells, coconut shells, palm shells, cocoa shells, etc.;

- Food processing waste: including grape pomace, grape vines, distillers grains, etc.

What Kind of BBQ Charcoal Machine to Invest?

A complete BBQ charcoal making machine typically comprises two essential parts:

Carbonization Machine

Charcoal Briquette Machine

Carbonization Machine – Convert Biomass into Charcoal Powder

BBQ charcoal machine is the heart of the machine.

- Pyrolysis Technology Principle: Biomass waste is placed in an oxygen-free, high-temperature reactor. Here, it undergoes dehydration, cellulose/hemicellulose/lignin decomposition, and removal of volatile components, ultimately forming high-calorific value charcoal.

- Raw Materials: Waste biomass (5-20mm size, moisture content below 15%)

- Finished Products: Loose charcoal powder

Watch the video to learn how Beston biomass pyrolysis plant operates.

Charcoal Briquette Machine – Shape Charcoal Powder into Briquettes

This part is essential for creating BBQ charcoal with specific sizes and shapes for optimal calorific value, transport, and storage performance.

- Function: Mix charcoal powder from the above carbonization stage with water, and binder uniformly. Then the machine applies pressure to form briquettes with specific shapes and sizes.

- Raw Materials: Charcoal powder, water, and binder

- Finished Products: Compact, sturdy BBQ charcoal briquettes

See the picture for a visual reference of Beston’s BBQ charcoal briquette machine.

Select Barbecue Charcoal Making Machine to Start Your Production

Beston Group’s BBQ charcoal machine comes in different capacities and designs to accommodate different raw materials and operating styles. For more details on how these machines work and to explore the available models, feel free to contact Beston Group.

Model BST-50

- BST-50S technology vetted by puro.earth

- 6,000 tons biochar production annually

- 7200H/Y stable&safe operation

- 4 Configuration options

Model BST-06

- 8000H/Y stable&safe operation

- Low-cost carbon removal process verification

- Small-scale test machine

- 2 Configuration options

| Model | BST-50 Standard | BST-50S LM | BST-50S HM | BST-50S MAX | BST-06 Standard | BST-06MAX |

|---|---|---|---|---|---|---|

| Time to Market | 2015 | 2022 | 2022 | 2022 | 2025 | 2025 |

| Operating Mode | Continuous | Continuous | Continuous | Continuous | Continuous | Continuous |

| Application | Commercial Scale | Commercial Scale | Commercial Scale | Commercial Scale | Testing | Testing |

| Dust Removal System | Standard | Advanced | Advanced | Advanced | Standard | Advanced |

| Feeding Capacity | 10-15m³/h | 10-15m³/h | 10-15m³/h | 10-15m³/h | 100-300KG/H | 100-300KG/H |

| Biochar Discharge Temperature | 45℃ | 45℃ | 45℃ | 45℃ | 45℃ | 45℃ |

| Puro.earth Authentication Model | × | √ | √ | √ | × | |

| Maximum Pyrolysis temperature | 650℃ | 650℃ | 650℃ | 850℃ | 650℃ | |

| Service Life | 5-8 years | 5-8 years | 5-8 years | 8-10 years | 5-8 years | |

| Annual Operating Time | 7200 hours | 7200 hours | 7200 hours | 7200 hours | 8000 hours | |

| Land Space Required (L*W*H*m) | 35m×15m×8m | 65m×15m×8m | 65m×15m×8m | 65m×15m×8m | 25m*18m*6m | |

| Total Power (KW) | 201.25kW | 453.35kW | 505.35kW | 505.35kW | 129.79 | 162.79 |

| Cooling Method | Recycling cooling Water | Industrial chiller | Industrial chiller | Industrial chiller | Recycling cooling Water | Industrial chiller |

| Installation Period (Calendar Days) | 50 | 70 | 70 | 70 | 45 | 50 |

Explore Various Shapes of Barbecue Charcoal Briquettes to Get

With the help of the barbecue charcoal production line, investors can obtain massive high-quality barbecue charcoal with specific sizes and specifications. For example, spherical barbecue charcoal, pillow-shaped BBQ briquettes, and oval barbecue charcoal.

Application Fields of Barbecue Charcoal

Family Barbecue

As an ideal barbecue fuel, this charcoal can provide continuous high temperature and long-term heat. Therefore, barbecue and grilled food can be heated evenly. Moreover, a delicious grilled taste and unique flavor can be obtained.

Catering Industry

BBQ charcoal made from BBQ charcoal making machine is also widely used in the catering industry, such as barbecue restaurants, hot pot restaurants, etc. Using such a kind of charcoal can improve the efficiency and quality of barbecue dishes.

Other Application of BBQ Charcoal

- Charcoal made from charcoal making machine can be used as fuel in industrial production, such as metallurgy, the chemical industry, and other fields.

- Since barbecue charcoal is derived from biomass, it can also function as biochar, offering benefits in soil remediation, carbon sequestration, animal feed additives, metal reductants, etc.

- For construction materials, BBQ charcoal can be used to make carbon bricks.

Core Design of Beston BBQ Charcoal Making Machine

Energy-saving Design

BBQ charcoal machine is equipped with a frequency conversion fan that intelligently adjusts airflow according to different biomass materials and processing requirements. This smart control improves system efficiency, reduces unnecessary energy consumption, and supports long-term, stable operation with lower operational costs and wider material adaptability.

Emission Control

The machine features a multi-stage EU-standard dedusting system that purifies exhaust gases through water washing, water spray, ceramic ring adsorption, and activated carbon filtration. This advanced treatment process effectively removes particulate matter and harmful substances, ensuring that final emissions fully comply with stringent EU environmental standards.

Automatic Design

- PLC: The programmable logic controller (PLC) of BBQ charcoal making machine automates key processes such as feeding, temperature control, and discharge. It also features a real-time alarm system that detects and isolates faults to ensure safe and stable operation.

- IoT: Enables real-time remote monitoring of key performance indicators. Operators can track system status, analyze operational trends, and access data via connected platforms anytime, anywhere.

Safety Protection

- Two-way explosion-proof device: Combining an explosion-proof hole and a water-sealed chamber, this system effectively prevents pressure-related accidents, ensuring safe reactor operation during high-temperature pyrolysis.

- Unique sealing design: The patented dynamic sealing structure of biochar pyrolysis equipment, featuring eight specialized seals, provides strong resistance to gas leakage, ensuring stable and secure system performance.

Global Customer Cases: Popular BBQ Charcoal Investment Project

Beton Group’s BBQ charcoal machine has been exported to many countries and regions around the world. We have a wide range of customer groups and rich export experience. Below are some successful cases.

Contact Us to Start Your Own BBQ Charcoal Business

BBQ charcoal making machine provides solutions for waste biomass management, and it has become the investment choice of many customers. The barbecue charcoal industry has excellent development potential all over the world. If you are willing to start your own BBQ charcoal business, don’t hesitate to contact us. Beston Group looks forward to cooperating with you sincerely. Follow us on Linkedin.