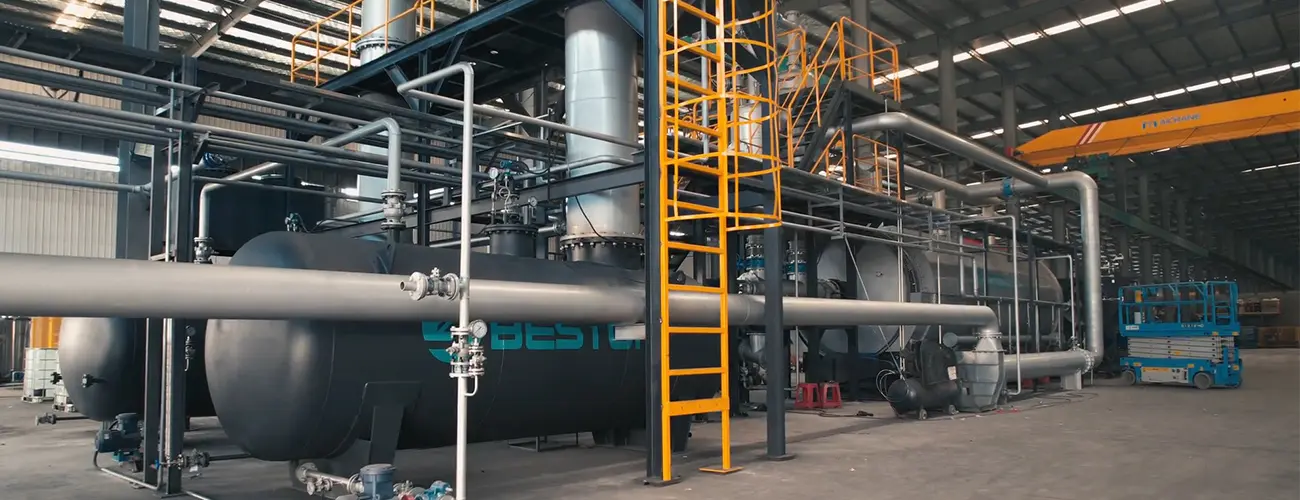

Tyre to oil plant brings innovative tyre recycling solutions with advanced pyrolysis technology. This equipment can process a large number of waste tyres while maximizing the value of tyre resources. Through pyrolysis process, waste tyres are converted into usable resources such as pyrolysis oil, carbon black and steel wire. Compared with landfill and incineration, this plant not only provides a sustainable way to deal with waste tyres, but also create considerable economic value.

Technical Innovations of BLJ-20 & BLL-30 Tyre to Oil Plant

BLJ-20

BLL-30

Fraction Distillation Technology

Get Naphtha & Non-Standard Diesel in One Process

This technology simultaneously collects naphtha (< 200°C) and non-standard diesel (> 200°C) to different oil tanks during pyrolysis.

- increase the oil value;

- reduce operations cost (including distillation equipment investment, labour and land cost, and energy consumption).

Large-capacity Pyrolysis Reactor (ø2800*10000)

50% ↑ in Processing Capacity

This expanded reactor size expands production scale and efficiency. It improves processing capacity for waste tyre from 12-15 tons/day to 18-20 tons/day.

Thermal Dynamic Sealing & Flexible High-temperature Insulation Technology

High Safety Factor

The technology greatly improves safety during pyrolysis reactor operation.

- better reactor sealing, no oil-gas leakage

- no open flames

- reduce thermal hazard risks

Oil Gas Anti-polymerization Condensation Technology

30 Days Non-stop Operation

The technology prevents system blockages and ensures stable output. BLL-30 continuous pyrolysis plant achieves:

- 30 day continuous operation

- process 10,000 tons of waste tyres annually

- less maintenance frequency

Hot Flue Gas Recirculation + Air Preheating Technology

↓55% Fuel Use & ↓50% Emissions

80% of recovered heat is reused to warm the reactor while the remaining 20% supports combustion for process continuity. Benefits:

- energy conservation

- better aligns with EU environmental standards.

Reactor Automatic Temperature Control Technology

±10°C Precise Temperature Control

A multi-media automatic temperature regulation system maintains tight control over thermal conditions in the reactor. It ensures:

- Maintains reactor temperature within a ±10°C margin.

- Adapts automatically to different fuel compositions.

Parameters of Beston Tyre Oil Plant for Sale

Continuous Type: BLL-30

- Process 6,000 tons waste plastic annually

- 30 day continuous operation

- High automation: two operators required

- Policy support and incentives

- Easy to get environmental compliance and approval

Batch Type: BLJ-20

- Process 4,000 tons waste plastic annually

- Get naphtha & non-standard diesel in one step

- 1 batch/day

Batch Type: BLJ-16

- Process 3,000 tons waste plastic annually

- 1 batch/day

- 4 Configuration options

| Model | BLL-30 | BLJ-20 | BLJ-16 Standard | BLJ-16 ULTRA |

|---|---|---|---|---|

| Manufacturer | BESTON | BESTON | BESTON | BESTON |

| Time to Market | 2025 | 2025 | 2013 | 2022 |

| Motor Brand | Chinese brand | Chinese brand | Chinese brand | ABB Explosion-proof |

| Suitable Raw Materials | Waste plastics; Tires; Oil sludge | Waste plastics; Tires; Oil sludge | Whole tire<120cm; Tire blocks<15cm; Oil soil with liquid content<30% | Waste plastics; Tires; Oil sludge |

| Input Capacity (Max.) | Waste plastic pellets: 0.8-1.05t/h Rubber powder: 1.25-1.5t/h Oil sludge:1.8-2.3t/h | Waste plastic pellets: 12-13t/d Tire: 18-20t/d Oil sludge:20-22t/d | Whole tire <120cm or Tire blocks<15cm: 10-12t/batch Sidewall removed tire: 15-16t/batch Oil soil: 16-18t/batch | Waste plastic bales: 8-10t/batch Whole tire <120cm or Tire blocks<15cm: 10-12t/batch Sidewall removed tire: 15-16t/batch Oil sludge: 16-18t/batch |

| Working Method | Fully Continuous | Batch | Batch | Batch |

| Final Oil Quality | Pyrolysis oil Pyrolysis oil with wax or naphtha | Pyrolysis oil, Non-standard diesel and naphtha | Pyrolysis oil | Pyrolysis oil Pyrolysis oil with wax or naphtha |

| Reactor Material | 304/310S Stainless steel | Q345R Boiler steel and 304/316L/310S Stainless steel | Q345R Boiler steel | 304 Stainless steel |

| Reactor Life Span (Years) | 5-8 | Q345R Boiler steel 2-3 304/316L Stainless steel 5-8 310S Stainless steel 8-10 | 2-3 | 5-8 |

| Guarantee (Months) | 12 | 12 | 12 | 12 |

| Delivery Time (Calendar Days) | 60-90 | 60 | 45 | 90 |

| Land Space Required (L*W*H*m) | 70*20*10 | 40*13*8 | 33*13*8 | 33*26*8 |

| Packing | 20*6*3m in bulk+13*40HQ | 1*40FR+4*40HQ | 1*40FR+3*40HQ | 1*40FR+8*40HQ |

| Installation Period (Calendar Days) | 60-90 | 45 | 45 | 60 |

Beston Global Cases: Export Tyre to Oil Plant Worldwide

BLJ-16 in Saudi Arabia

Project Goals

The Saudi customer needed an efficient and legal way to handle a large number of waste tires.

Project Status

Installation Completed | Operating

Project Outcomes

- Processes 12 – 16 tons per batch, with an annual capacity of up to 4,000 tons.

- Efficiently converts waste tires into pyrolysis oil and carbon black, increasing product value and resource use.

BLJ-16 in Sudan

Project Goals

The client in Sudan has access to a large volume of waste tires and aims to convert them into tire pyrolysis oil (TPO) for commercial use.

Project Status

Installation Completed | Operating

Project Outcomes

- Choose BLJ-16 tire to oil plant, process 10 – 12 tons of waste tires per batch

- The client sells the recovered oil to buyers and generates profit from the operation

BLJ-16 in Nigeria

Project Goals

The Nigerian customer need to transform waste tires into valuable resources and generate additional revenue.

Project Status

Installation Completed | Operating

Project Outcomes

- Process 10 – 12 tons of waste tires per batch

- Produce carbon black and pyrolysis oil (oil yield about 40%)

- Gain operational experience to expand to plastic and oil sludge pyrolysis

Tyre to Oil Process: From a Molecular Perspective

To get fuel oil from tyre, the focus is on the pyrolysis reaction. This is a high temperature, micro-oxygen reaction that occurs when the tire goes to tyre to oil plant. It usually involves the thermal decomposition of the rubber components of the tyre.

Reaction Components of Tyre Pyrolysis

Natural Rubber:

- Main Component: Polyisoprene.

- Structure: (−CH2−C(CH3)=CH−CH2−)n

Synthetic Rubber:

- Main Component: Styrene-Butadiene copolymer.

- Structure: [−CH2−CH(C6H5)−]m−[−CH2−CH=CH−CH2−]n

Reaction Stage in Tyre Pyrolysis

Polymer Chain Cleavage:

Long-chain polymer molecules of tyre break at high temperatures to produce free radicals. Free radicals further induce chain cleavage to generate small molecule olefins, such as C5 (isoprene), C4 (butene), C6 (hexene), etc. This process also forms light hydrocarbons like methane and ethylene.

Cracking & Recombination:

Small molecule olefins will continue to crack or recombine to form C5-C10 hydrocarbon molecules. The aromatic ring part of styrene in synthetic rubber may produce aromatic compounds such as benzene and toluene at high temperatures. Small molecular hydrocarbons formed by tyre pyrolysis plant form pyrolysis oil from the condensable part.

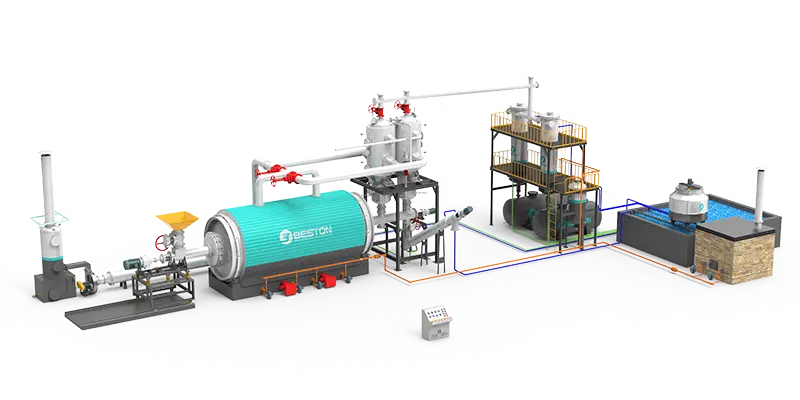

Tyre to Oil Recycling Process

If you want to understand the tyre to oil recycling process, it is more intuitive to start with the system structure of the tyre to oil plant. Below is the workflow of the entire tire to oil production line.

01 Raw Material Feeding

02 Pyrolysis System

03 Condensation System

04 Flue Gas Treatment System

05 Water-Cooled Slag Discharging System

Applications of Tire to Oil Recycling Products

Tyre Pyrolysis Oil

As Fuel

It can be directly burned as an industrial fuel and is generally sold to glass factories, steel factories, ceramic factories, cement factories, etc.

Processed into Naphtha

After distillation, naphtha is obtained to use in plastic manufacturing or as a solvent.

Generate Electricity

After distillation, non-standard diesel components can be used in heavy oil generator sets to generate electricity.

Naphtha / Non-Standard Diesel

Naphtha / Naphtha from Non-condensable Gas

- used to make propylene, butadiene, and ethylene for plastics, rubber, and other synthetic materials.

- used to make gasoline, kerosene, jet fuel, and other fuels.

- as a solvent in industry and labs.

Non-Standard Diesel

- as industrial fuel to replace traditional fuel oil.

- Used as fuel for diesel generators to Power Generation: .

- as Marine & Construction Machinery Fuel

Oil Rate Report of Beston Tire to Oil Plant

As an important performance indicator of a tyre oil plant, the oil rate determines the cost-effectiveness of the investment. A machine with an excellent oil rate will produce more tire pyrolysis oil. Thereby creating more economic value. Beston Group has been committed to developing equipment with higher production efficiency. Therefore, we do experiments based on different types of tire raw materials. Below is the experimental data from Beston’s technical team for your reference.

| Raw material | Details | Oil rate | Steel wire | Carbon black | Gas/water |

|---|---|---|---|---|---|

| Waste tire | Truck tires | 45%-50% | 15%-20% | 30% | 5%-10% |

| Car tires | 40%-45% | 10%-15% | 40% | 5%-10% | |

| Bicycle/motorcycle tires | 30%-35% | 5%-10% | 10% | 5%-10% |

Environmental Contributions of Tire to Oil Plant

Waste Reduction

Tyre oil plant plays a vital role in reducing solid waste. By processing discarded tires, the equipment diverts large volumes of non-biodegradable materials away from landfills. This not only conserves landfill space but also prevents long-term environmental degradation caused by slow tire decomposition.

Pollution Prevention

Open burning of tires releases toxic gases, particulate matter, and harmful chemicals into the atmosphere. Tyre to oil technology eliminates the need for burning, offering a clean and contained process. This significantly reduces air pollution and protects both ecosystems and human health.

Resource Recovery

The pyrolysis process enables the recovery of useful resources from waste tires. It generates valuable carbon black and TPO that can be reused in industrial applications. This helps reduce dependence on fossil resources and supports circular economy practices.

Promotes Sustainable Development

Tyre to oil plant offers an environmentally responsible method of waste disposal. Pyrolysis plant contributes to lower greenhouse gas emissions when compared to traditional methods. As more countries seek green solutions for waste management, the system supports the global transition toward sustainable development.

Partner with Beston Group to Launch Tyre to Oil Project

Tyre to oil plant offers an effective solution for recycling waste tires, transforming environmental burdens into valuable resources. If you’re dealing with a large number of discarded tires and seeking a sustainable disposal method, contact us for a customized solution. Our project consultants will get back to you within 24 hours. Join us in creating a cleaner future! Follow us on LinkedIn for the latest updates and insights.