Small pyrolysis machine – BLJ-16 is a cost-effective solution for waste management. Through pyrolysis technology, BLJ-16 can realize resource utilization and treatment of waste such as plastics, oil sludge, and tyres. This pyrolysis process produces end products like pyrolysis oil and carbon black, both of which have wide applications in industrial and commercial sectors. At present, this equipment has become the choice of many investors for waste recycling projects.

What is Small Pyrolysis Machine?

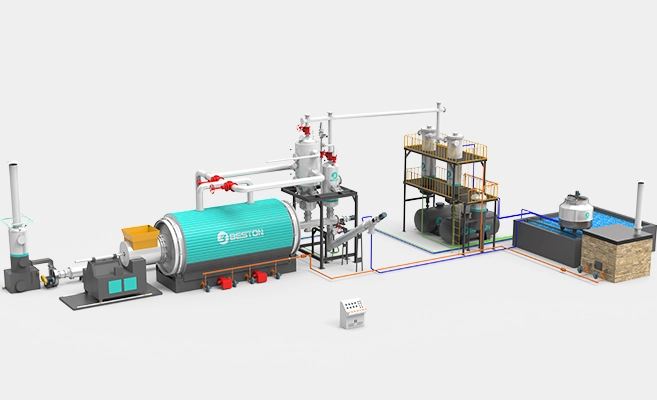

Typically, pyrolysis equipment is composed of feeding system, reactor, condenser, discharger, and waste gas treatment system.

⚙️ Working Principle: Small pyrolysis plant is designed to operate in batch mode, processing one furnace of raw materials per day. In each batch run, raw materials such as plastics, oil sludge, or tyres are fed into the reactor and undergo pyrolysis for a specific period. Once the pyrolysis stage concludes, the entire operation of BLJ-16 shifts into the cooling phase. After cooling, the by-products are discharged and the system is reloaded with raw materials to start the next batch.

BLJ-16 Pyrolysis Plant: Solving Plastic, Tyre & Oil Sludge Processing Challenges

While different feedstocks bring distinct processing challenges, our BLJ-16 small pyrolysis machine incorporates specialized upgrades to overcome typical bottlenecks and unlock higher profitability:

Plastic Waste

3000 tons/year processing capacity

Applies catalytic dewaxing technology to break down heavy wax components during pyrolysis, effectively preventing wax oil condensation and blockage for stable, continuous operation.

- Increases production efficiency by 200%

- Delivers plastic pyrolysis oil qualified for ISCC certification

Waste Tyres

4000 tons/year processing capacity

Employs precise thermal control during pyrolysis to reduce TPH in carbon black, followed by grinding and pelletizing to upgrade it into high-value N330/N550/N660 grades.

- Increases carbon black surface area and market value, boosting up to 5 times on ROI

- Enhance the overall return per ton of waste tyres

Oil Sludge

6000 tons/year processing capacity

Combines decanter centrifuge + thermal washing + pyrolysis technology to remove impurities and reduce thermal resistance, significantly lowering the risk of coking and improving reaction stability.

- Improves processing throughput by 200%

- Reduces plant wear and extends service life

Basic Parameters of Beston Small Pyrolysis Machine for Sale

| Model | BLJ-16 Standard | BLJ-16 TDU | BLJ-16 WAX | BLJ-16 CAT | BLJ-16 ULTRA |

|---|---|---|---|---|---|

| Manufacturer | BESTON | BESTON | BESTON | BESTON | BESTON |

| Time to Market | 2013 | 2013 | 2022 | 2022 | 2022 |

| Motor Brand | Chinese brand | Chinese brand | Chinese brand | Chinese brand | ABB Explosion-proof |

| Suitable Raw Materials | Whole tire<120cm; Tire blocks<15cm; Oil soil with liquid content<30% | Oil sludge; Landing oil sludge; Drilling waste; Tank bottom oil sludge | Waste plastic bales (Max.0.9*0.9*1.6m) | Waste plastic bales (Max.0.9*0.9*1.6m) | Waste plastics; Tires; Oil sludge |

| Input Capacity (Max.) | Whole tire <120cm or Tire blocks<15cm: 10-12t/batch Sidewall removed tire: 15-16t/batch Oil soil: 16-18t/batch | 16-18t/batch | 8-10t/batch | 8-10t/batch | Waste plastic bales: 8-10t/batch Whole tire <120cm or Tire blocks<15cm: 10-12t/batch Sidewall removed tire: 15-16t/batch Oil sludge: 16-18t/batch |

| Working Method | Batch | Batch | Batch | Batch | Batch |

| Final Oil Quality | Pyrolysis oil | Pyrolysis oil | Pyrolysis oil with wax | Pyrolysis oil with naphtha | Pyrolysis oil Pyrolysis oil with wax or naphtha |

| Reactor Material | Q345R Boiler steel | 304 Stainless steel | 304 Stainless steel | 304 Stainless steel | 304 Stainless steel |

| Reactor Life Span (Years) | 2-3 | 5-8 | 5-8 | 5-8 | 5-8 |

| Guarantee (Months) | 12 | 12 | 12 | 12 | 12 |

| Delivery Time (Calendar Days) | 45 | 60 | 60 | 60 | 90 |

| Land Space Required (L*W*H*m) | 33*13*8 | 33*13*8 | 33*13*8 | 33*13*8 | 33*26*8 |

| Packing | 1*40FR+3*40HQ | 1*40FR+3*40HQ | 1*40FR+3*40HQ | 1*40FR+3*40HQ+1*20GP | 1*40FR+8*40HQ |

| Installation Period (Calendar Days) | 45 | 45 | 45 | 45 | 60 |

Small Pyrolysis Plant Vs. Continuous Pyrolysis Plant

Small Scale Pyrolysis Equipment: BLJ-16

- Raw Material Requirement: No special requirements; final feed size depends on furnace door dimensions

- Automation: Lower automation level, each process must start after the previous one is completed

- Annual processing capacity: Plastic: 3,000 tons; tyres: 4000 tons; oil sludge: 6000 tons.

- Target customer: Suitable for small and medium production needs

Continuous Pyrolysis Plant: BLL-30

- Raw Material Requirement: Material must be clean and pre-crushed before feeding.

- Automation: Higher automation level, can operate continuously for up to 30 days

- Annual processing capacity: Plastic: 4,000 tons; tyres: 6000 tons; oil sludge: 7500 tons.

- Target customer: BLL-30 is suitable for large production needs

From Trash to Treasure: Raw Materials for Small Pyrolysis Plant

Waste Plastic

Oil Sludge

Waste Tyre

- Source: waste plastic recycling center management, urban domestic waste disposal, plastic product manufacturers, etc.

- Type: pure plastic, such as PE, PP, PS, ABS, etc. Waste plastic products, such as plastic packaging, plastic cables, agricultural mulch, etc.

- Pyrolysis Products: pyrolysis oil, carbon black, syngas.

Note:

- PET and other oxygen-containing plastics do not produce oil during pyrolysis. Moreover, such plastics release oxygen during pyrolysis, which does not meet the anaerobic reaction conditions of plastic pyrolysis plant.

- PVC and other chlorine-containing plastics produce hydrogen chloride after pyrolysis, which corrodes pipelines. In addition, the finished oil contains chlorine. Burning this oil releases dioxins, a carcinogen.

- Source: Oil drilling, transportation and refining, ship repair and manufacturing, oil waste management.

- Type: Oil-based drilling cuttings, oil-contaminated soil, oil tank bottom sludge, refinery sludge and other industrial oily wastes.

- Pyrolysis Products: pyrolysis oil, sand, syngas.

Note:

- Oil sludge has complex composition. We recommend that customers send samples for testing and then confirm the process plan of thermal desorption unit.

- Source: Tire recycling, fleet transportation, heavy industrial machinery production.

- Type: Passenger tyre, commercial tyre, OTR tyre.

- Pyrolysis Products: pyrolysis oil, carbon black, steel wire, syngas.

Usage of End Products Obtained from Small Pyrolysis Machine

The end products produced by small scale pyrolysis equipment of each raw material are different. In particular, the reaction of each raw material produces syngas. It is reused in the pyrolysis reaction. The remaining products have a wide range of applications in various fields.

Pyrolysis Oil

- Used as alternative fuel for energy-intensive factories such as steel mill, cement plant, and power plant;

- Further distilled into naphtha and non-standard diesel with higher commercial value for sale;

- Naphtha is used as chemical feedstock, fuel production, and industrial & laboratory solvent.

Carbon Black

- Further processed into higher quality carbon black, such as N330 carbon black;

- Used as an additive for asphalt mixtures, printing inks, black dyes, paints, etc.

Steel Wire

- Reused in tire production;

- Reprocessed into other metal products for sale.

Sand

- Used to produce permeable bricks;

- Reprocessed into oil well anti-collapse materials.

Working Process Description of Small Pyrolysis Machine

01Preheating (3h)

Use a burner to preheat the small pyrolysis reactor. Generally, natural gas, diesel, and heavy oil are used as preheating fuels.

02Feeding (2-3h)

03💡Reaction (7-11h)

When the temperature of the reactor reaches 180℃, the reaction begins. When the reaction reaches 280-350℃, the reaction tends to stabilize. The entire reaction involves the following processes:

- Pyrolysis: Under the thermal desorption process, high molecular weight hydrocarbon polymers in the raw materials undergo chain scission into small molecule gaseous hydrocarbons. These high-temperature gaseous hydrocarbons are oil gas.

- Condensation: Oil gas enters the manifold first. After separating the heavy oil and impurities, the high-temperature oil gas enter the condenser. Condensable components are condensed to form pyrolysis oil, which is collected by the oil storage tank.

- Syngas Reuse: Non-condensable components in oil gas, namely syngas, first enter the water seal for purification. Later, it enters the combustion system through the pipeline as fuel to provide energy for the reaction.

- Exhaust Gas Discharge: Flue condenser and spray tower cool down and remove dust from exhaust gas. Finally, chimney discharges the exhaust gas.

04Cooling (5-6h)

When the oil yield decreases and the oil turns dark brown, the oil extraction process is essentially complete. After the reaction is completed, the small pyrolysis plant is cooled down. This is to prepare for the subsequent discharging.

05Discharging (2-3h)

Diverse Configuration Scheme for Batch Pyrolysis Plant

Small pyrolysis machine adopts flexible component layout and modular design. Therefore, you can customize the configuration according to site conditions and production requirements. By the way, these configuration options are an important part of small pyrolysis plant cost.

The feeding system of small scale pyrolysis equipment can be divided into three categories according to working efficiency: manual, hydraulic and screw feeding:

| Feeding Method | Feeding Size | Working Efficiency |

|---|---|---|

| Manual | less than 1.2m | low |

| Hydraulic | less than 1.2m | high |

| Screw | less than 5cm | high |

The reactor of a small scale pyrolysis unit is the core component for the reaction. The reactor material must be selected based on the characteristics of different pyrolysis feedstocks. For example, plastics require a higher pyrolysis reaction temperature, which demands greater heat resistance from the reactor material. The following are three commonly used materials.

| Furnace Material | Features | Suitable Raw Materials |

|---|---|---|

| 310S Stainless Steel | Can withstand high temperature of 1035℃; High temperature oxidation corrosion resistance; Acid corrosion resistance. |

waste plastic |

| 304 Stainless Steel | Can withstand high temperature of 600-700℃ | oil sludge, scrap tyre |

| Q345R Steel | Can withstand high temperature of 450℃ | oil sludge, scrap tyre |

After pyrolysis, the solid residue needs cooling. The discharge system of small-scale pyrolysis equipment uses a water-cooled screw discharger, available with one or three units. The 3 screw discharger choice has a shorter cooling time for the reactor and the solid residue.

| Discharging Method | Furnace Cooling Temperature | Cooling Time | Solid Residue Temperature |

|---|---|---|---|

| 1 screw conveyor | 50-60℃ | long | 100-150℃ |

| 3 screw conveyors | 150℃ | short | 50-80℃ |

Additional Equipment for Small Pyrolysis Machine

Catalytic Tower

For small plastic pyrolysis machine, catalytic tower can solve the problem of wax oil blocking pipeline during pyrolysis process. Thus, it improves reaction efficiency and oil quality.

Tyre Shredder

For tyre pyrolysis machine equipped with screw feeding, tyre need to be processed into rubber powder. The equipment can achieve tyre cutting, crushing and steel wire removal, etc.

Oil Distillation Equipment

This equipment further purifies the pyrolysis oil through distillation. The pyrolysis oil is converted into naphtha and non-standard diesel, which has higher utilization and commercial value.

High-end Exhaust Gas Treatment System

In order to meet the high emission standards in some regions, we provide high-end exhaust gas treatment equipment. The exhaust gas treated by this equipment can meet EU standards.

Cutting-edge Technology of Beston Small Scale Pyrolysis Plant

Nitrogen System

The function of the nitrogen system is to introduce nitrogen for gas replacement before ignition and discharge. Through nitrogen replacement, the residual combustible oil gas in the reactor can be effectively removed. This can prevent the flash explosion of the reactor, thereby ensuring the safe and stable operation of the small pyrolysis machine.

Floating Seal Technology

The floating seal technology adopts a sealing method that combines carbon fiber and high-temperature soft filler. Compared with the traditional graphene packing sealing technology, this combined sealing form has high temperature resistance, corrosion resistance and wear resistance. This technology can stably guarantee the sealing of pyrolysis process for a long time.

Intelligent Control System

The intelligent control mode integrates PLC/DCS systems with optional IoT monitoring, ensuring efficient, automated operation. Real-time data insights enable quick adjustments, reduce manpower needs, and improve the working environment. This advanced control approach enhances overall operational efficiency while giving customers greater visibility and flexibility in managing production.

Flare System

Excess syngas may cause safety hazards of small pyrolysis unit overpressure and storage. Emergency incidents such as power outages that may occur during equipment operation. To prevent these potential safety hazards, the flare system can be quickly activated in the event of pressure or power abnormalities. This ensures the safe discharge of syngas and prevents system overpressure.

Small Pyrolysis Machine Creates Diversified Value for Investors

Economic Benefit

- As the global demand for clean energy and alternative materials continues to increase, pyrolysis end products such as pyrolysis oil, carbon black, are highly competitive in the market. This ensures a stable sales channel and profitable pyrolysis projects.

- Small scale pyrolysis equipment usually have a shorter investment return cycle, and investors can see economic benefits in a shorter period of time. This reduces investment risks and ensures the long-term stable operation of the project.

Sustainability Promotion

- Small pyrolysis plant significantly reduces the landfill and incineration of waste. This can not only effectively reduce the emission of harmful substances, but also the pollution risk of natural resources. This plays a positive role in the protection of the ecosystem.

- Through the application of advanced pyrolysis technology, the machine plays a key role in energy saving and emission and promoting resource recycling. This conforms to the strategic goals of global environmental protection and sustainable development.

Social Influence

- Operation of the pyrolysis project drives the development of local related industrial chains. The entire industrial chain ranges from supply chain to product processing, and then to sales and services. This can also provide a large number of employment opportunities.

- As the core of the emerging industry, the small pyrolysis machine has attracted a large number of investments and support from related industries and local governments. This industrial structure optimization enhances the diversity of the local economy.

Market Prospects of Small Scale Pyrolysis Unit in Different Regions

In Europe

In Middle East & Africa

In Asia

The main types of waste in Europe are plastics and oil sludge. The recycling status of these wastes in Europe has the following characteristics:

- Strict Waste Regulatory: European countries have a strict regulatory system for waste disposal. Taking the plastic ban as an example, many countries ban the use of disposable plastic products, further promoting the recycling of plastic waste.

- Government Support: The government implements policies to support recycling projects. It also encourages innovative waste treatment facilities such as batch pyrolysis plant through large amounts of funding.

- Sustainable Transformation: More and more European companies regard sustainable development and circular economy as an important part of their corporate strategy. They actively seek new methods of waste treatment and recycling.

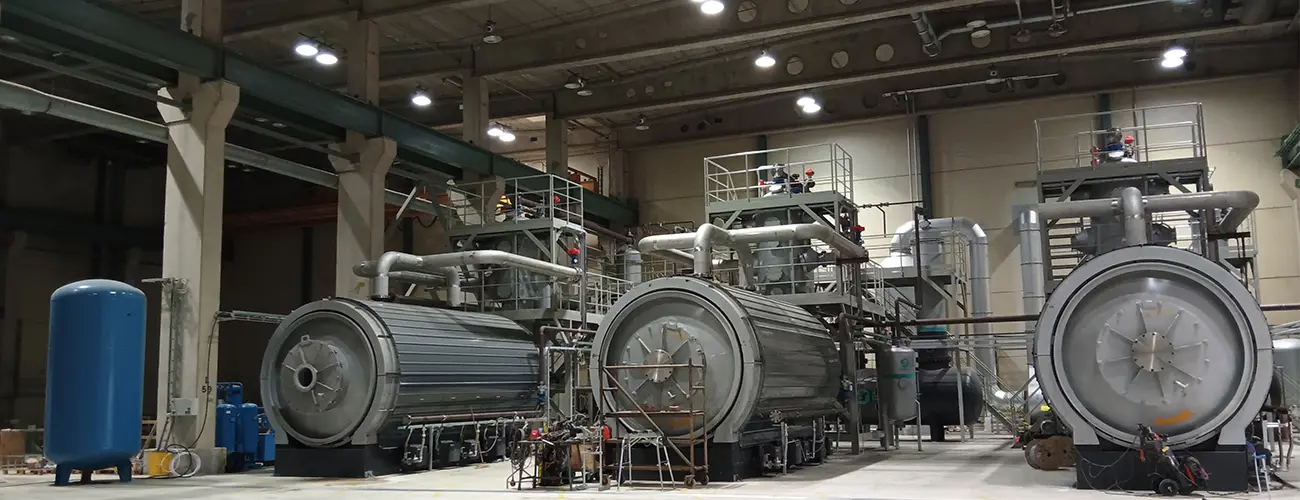

Therefore, the prospects of small pyrolysis machine, especially plastic to fuel machine in the European market are very broad. Pyrolysis machines can effectively process wastes such as plastics and oil sludge, which meets the European market’s demand for efficient and environmentally friendly waste treatment technology. The following are successful cases of Beston Group’s pyrolysis projects in Europe:

The main types of waste in these regions are oil sludge and tires. The current status of waste recycling projects in the Middle East & Africa is as follows:

- Lack of Recycling Facilities: The lack of professional recycling technologies and facilities has led to greater investment in waste recycling infrastructure.

- Strengthened Policy Support: Although some countries still have a long way to go in terms of waste recycling policies, more and more countries are beginning to formulate and implement more systematic waste management and recycling policies.

- Economic Opportunities Emerge: These regions have great potential for economic development. Increasing industrial activities and urbanization have driven the demand for efficient waste treatment technologies.

Currently, recyclers in these regions are in the initial stage of investing in pyrolysis projects on a small scale. In other words, it brings great potential for future project expansion. Thus, small scale pyrolysis unit is currently becomes a key option for solving waste disposal problems in these regions. The following are pyrolysis projects carried out in these regions:

Asia is now facing the challenge of sustainable recycling of plastics, oil sludge and tires. The background of the construction of waste recycling projects in the region is as follows:

- Waste Accumulation: Rapid economic growth and urbanization in many Asian countries have led to a large amount of waste generation.The many environmental problems caused by waste accumulation have attracted attention from many parties.

- Improving Recycling System: Many Asian countries have made significant progress in waste recycling in recent years and established a relatively complete waste recycling system. All countries use market incentives to promote the development of waste resource utilization.

- Recycling Awareness Awakening: As the concept of sustainability continues to permeate, the environmental awareness of the public and enterprises in Asian countries has gradually increased. More and more investors are committed to waste recycling projects.

The Asian market has great potential for small pyrolysis plant. Rapid urbanization and large amounts of industrial waste have driven the demand for efficient waste treatment technology. Countries are also gradually realizing the importance of waste management and ecological protection. The following are successful cases of Beston Group pyrolysis projects in Asia:

Start Your Pyrolysis Project with Beston Group

If you are interested in a small pyrolysis machine, Beston Group is your reliable choice. As a professional manufacturer with strong expertise and extensive experience, we provide comprehensive support throughout your purchasing process. To learn more about this plant, feel free to contact us directly. Our project managers will offer tailored solutions and designs to meet your specific needs. You can also explore more details about our pyrolysis projects on LinkedIn.