Beston pyrolysis reactor has adopted the latest design and technology, to achieve the fully recycling of waste. As the core component of the entire production line setup, the reactor directly affects pyrolysis efficiency and stability of the entire system. Therefore, choosing the most suitable pyrolysis reactor for sale is critical for waste recycling project. Beston Group provides a comprehensive product line and flexible configuration solutions. We are your excellent choice as an integrated pyrolysis solution provider.

Thermal Decomposition Pathways in Pyrolysis Reactor

Pyrolysis reactor is the core of pyrolysis machine. The reaction is carried out in a high-temperature micro-oxygen environment. Plastic, oil sludge, and tyre undergo thermal decomposition to form high-temperature oil gas and solid residues. Thermal decomposition pathways inside the reactor are followings:

NO.1 Molecular Sond Scission

Under high-temperature and oxygen-deficient conditions, the macromolecular chains in plastics, rubber, and oil sludge (C–C, C–H bonds) are broken. This generates smaller molecular fragments, and free radicals.

NO.2 Volatile Formation

The cracked small and medium molecules are released as gaseous products (hydrocarbons, hydrogen, carbon monoxide, etc.). Some condense into pyrolysis oil, while others remain as combustible syngas.

NO.3 Solid Formation

The non-volatile fraction (fixed carbon + inorganic matter) remains as solid residues. These include industrial additive residues, carbon black, mineral ash, and metals, which are basically harmless.

Conversion Mechanisms of Waste Inside Pyrolysis Reactor

Waste Plastic

Oil Sludge

Waste Tyre

Plastic is composed of polymers, which are long-chain hydrocarbons such as polyethylene (PE), polypropylene (PP), polystyrene (PS), etc.

Components Involved in Pyrolysis:

- Polyolefin Chains: These chains are mainly composed of PE or PP units, which break down into smaller alkanes and alkenes.

- Aromatic Rings: These rings present in PS break down into smaller aromatic compounds such as benzene, toluene and styrene.

Decomposition Products:

- Oil gas mixture of alkanes, olefins and aromatic compounds.

- Inorganic Residues containing residual carbon black and inorganic substances.

Oil sludge is generated during the oil extraction or refining process. It is a mixture containing hydrocarbons, water, inorganic materials and trace amounts of heavy metals.

Components Involved in Pyrolysis:

- Heavy Hydrocarbons: These large hydrocarbon molecules, such as asphaltenes and resins, break down into smaller alkanes, olefins and aromatic compounds.

- Organic Compounds: Other organic compounds, including alcohols, ketones, and esters.

Decomposition Products:

- Oil gas mixture of alkanes, olefins and aromatic compounds.

- Inorganic residues remaining inorganic materials, mainly in the form of sand or coke.

Tyre is mainly made of synthetic rubber. It contains a complex mixture of organic compounds, including styrene-butadiene rubber (SBR), polyisoprene (IR) and carbon black.

Components Involved in Pyrolysis:

Rubber Molecules: Long chains of rubber molecules, mainly composed of SBR and IR, will break down into smaller hydrocarbons, including isoprene, butadiene, styrene and benzene in tire pyrolysis reactor.

Decomposition Products:

- Oil gas mixture of alkanes, olefins and aromatic compounds.

- Carbon black, a valuable industrial material

- Steel wire in tyre remains intact as a solid residue.

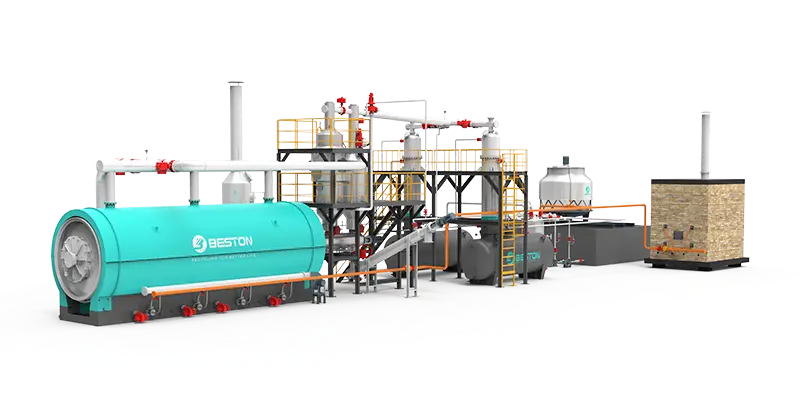

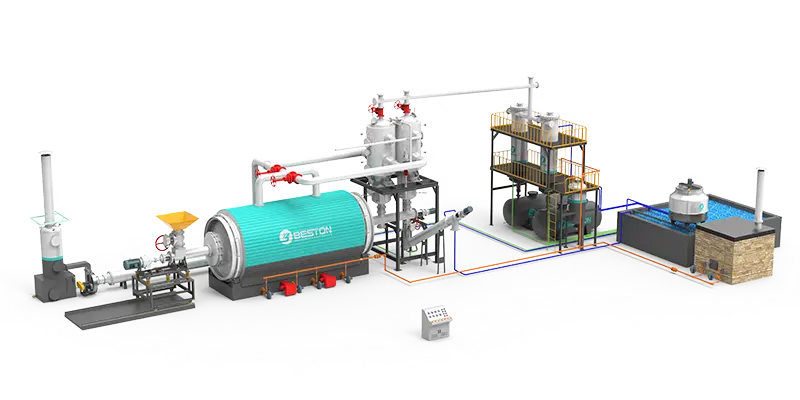

Pyrolysis Reactor Types for Complete Pyrolysis Line

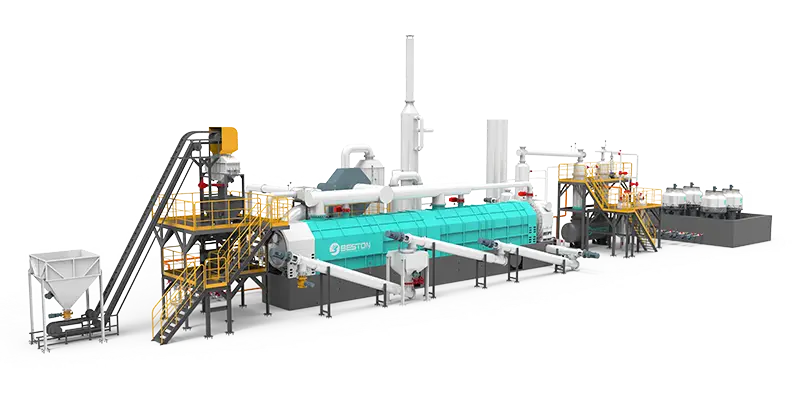

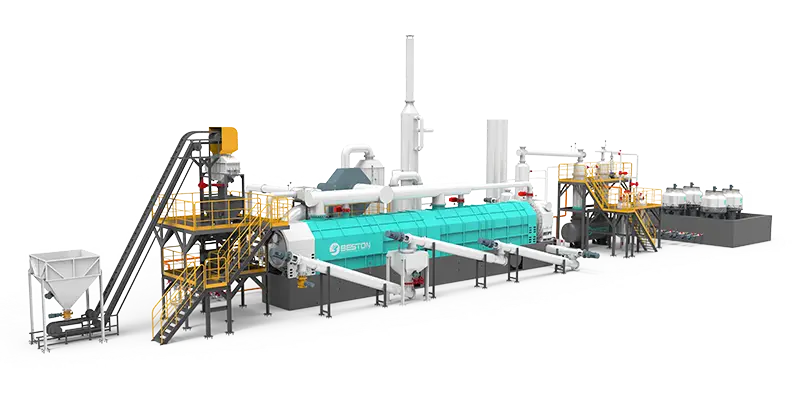

Continuous Type: BLL-30

- Large-scale processing choice

- 30 day continuous operation

- High automation: 2 operators required

- Policy support and incentives

- Easy to get environmental compliance and approval

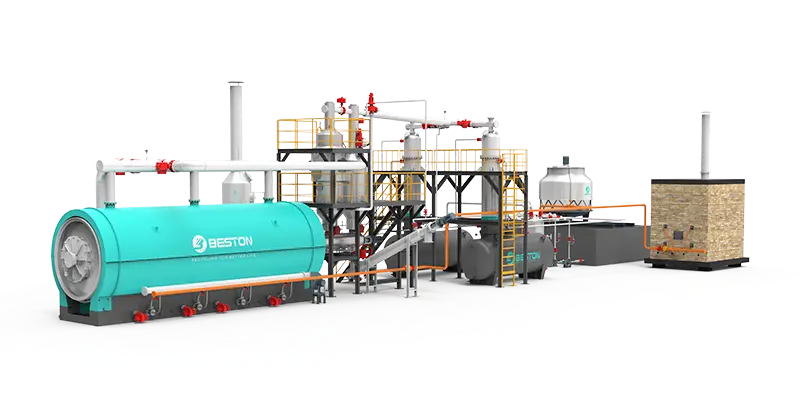

Batch Type: BLJ-20

- Large-capacity Pyrolysis Reactor (ø2800*10000)

- Get naphtha & non-standard diesel in one step

- 1 batch/day

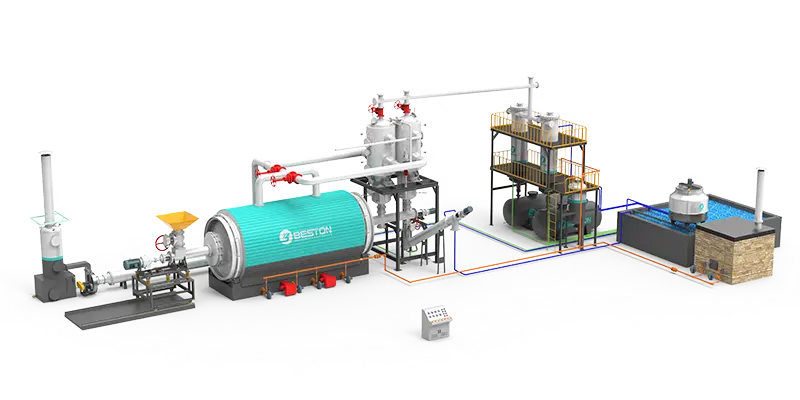

Batch Type: BLJ-16

- Small processing choice

- 1 batch/day

- 3 Configuration options

| Model | BLL-30 | BLJ-20 | BLJ-16 Standard | BLJ-16 TDU | BLJ-16 WAX | BLJ-16 CAT | BLJ-16 ULTRA |

|---|---|---|---|---|---|---|---|

| Time to Market | 2025 | 2025 | 2013 | 2013 | 2022 | 2022 | 2022 |

| Motor Brand | Chinese brand | Chinese brand | Chinese brand | Chinese brand | Chinese brand | Chinese brand | ABB Explosion-proof |

| Suitable Raw Materials | Waste plastics; Tires; Oil sludge | Waste plastics; Tires; Oil sludge | Whole tire<120cm; Tire blocks<15cm; Oil soil with liquid content<30% | Oil sludge; Landing oil sludge; Drilling waste; Tank bottom oil sludge | Waste plastic bales (Max.0.9*0.9*1.6m) | Waste plastic bales (Max.0.9*0.9*1.6m) | Waste plastics; Tires; Oil sludge |

| Input Capacity (Max.) | Waste plastic pellets: 0.8-1.05t/h Rubber powder: 1.25-1.5t/h Oil sludge:1.8-2.3t/h | Waste plastic pellets: 12-13t/d Tire: 18-20t/d Oil sludge:20-25t/d | Whole tire <120cm or Tire blocks<15cm: 10-12t/batch Sidewall removed tire: 15-16t/batch Oil soil: 16-18t/batch | 16-18t/batch | 8-10t/batch | 8-10t/batch | Waste plastic bales: 8-10t/batch Whole tire <120cm or Tire blocks<15cm: 10-12t/batch Sidewall removed tire: 15-16t/batch Oil sludge: 16-18t/batch |

| Working Method | Fully Continuous | Batch | Batch | Batch | Batch | Batch | Batch |

| Final Oil Quality | Pyrolysis oil Pyrolysis oil with wax or naphtha | Pyrolysis oil, Non-standard diesel and naphtha | Pyrolysis oil | Pyrolysis oil | Pyrolysis oil with wax | Pyrolysis oil with naphtha | Pyrolysis oil Pyrolysis oil with wax or naphtha |

| Reactor Material | 304/310S Stainless steel | Q345R Boiler steel and 304/316L/310S Stainless steel | Q345R Boiler steel | 304 Stainless steel | 304 Stainless steel | 304 Stainless steel | 304 Stainless steel |

| Reactor Life Span (Years) | 5-8 | Q345R Boiler steel 2-3 304/316L Stainless steel 5-8 310S Stainless steel 8-10 | 2-3 | 5-8 | 5-8 | 5-8 | 5-8 |

| Guarantee (Months) | 12 | 12 | 12 | 12 | 12 | 12 | 12 |

| Delivery Time (Calendar Days) | 60-90 | 60 | 45 | 60 | 60 | 60 | 90 |

| Land Space Required (L*W*H*m) | 70*20*10 | 40*13*8 | 33*13*8 | 33*13*8 | 33*13*8 | 33*13*8 | 33*26*8 |

| Packing | 20*6*3m in bulk+13*40HQ | 1*40FR+4*40HQ | 1*40FR+3*40HQ | 1*40FR+3*40HQ | 1*40FR+3*40HQ | 1*40FR+3*40HQ+1*20GP | 1*40FR+8*40HQ |

| Installation Period (Calendar Days) | 60-90 | 45 | 45 | 45 | 45 | 45 | 60 |

Technical Advantages of the Pyrolysis Reactor

Thermal Efficiency

- Hot Air Heating: For BLL-30, hot flue gas mixed with hot air heats pyrolysis reactor, reducing fuel use by 55%.

- Anti-Coking: Mechanical coke cleaning structure improves thermal efficiency and prevents uneven material heating.

Safety

- Dynamic Sealing: Multi-component sealing ensures airtightness, preventing oil/gas leaks and open flames.

- Flexible Insulation: The design maintains safe exterior temperatures and significantly reduces thermal hazards.

Automation

- Temperature Control: For BLL-30, the reactor achieves temperature automatic adjustment with ±10℃ accuracy.

- PLC Intelligent Control: Full-process visual management with real-time adjustment of temperature & pressure.

Main Components of Pyrolysis Reactor for Sale

01Drive System

02Base

03Burner

04Main Furnace

05Casing

Pyrolysis Reactor Cost Analysis: Continuous vs. Batch

Continuous Reactor

- Furnace Design: Large 310S stainless steel furnace. High material and manufacturing costs. Suited for long-term operation.

- Manufacturing Complexity: Complex internal structure. Precise welding and sealing required. Longer manufacturing cycle costs.

- Technology Integration: Equipped with high-cost automation systems. Reduces labor intensity and lowers skill requirements.

- Component Requirements: Many internal liners, seals, and precision parts. Raises costs of the pyrolysis reactor.

Batch Reactor

- Furnace Design: Medium furnace. 310S, 304, or Q345R optional. Lower investment and fits small-scale production.

- Manufacturing Complexity: Simple structure. Easy manufacturing and fast assembly. Lower costs and quick to deploy.

- Technology Integration: Lower technology investment. Operation relies more on manual skills and labor.

- Component Requirements: Simple internal structure and fewer components. Easier maintenance and lower reactor costs.

Advanced Technologies Compatible with Pyrolysis Reactor

Flash Explosion Prevention

The nitrogen system introduces inert gas, nitrogen, into the main furnace before and after the reaction. This evacuates excess oxygen and pyrolysis oil gas inside the pyrolysis chamber. This prevents flash explosions. In addition, the main furnace automatically opens a safety valve to release pressure when overpressure occurs. This prevents equipment damage due to overpressure.

Catalytic System

This system is widely used in plastic to fuel process. In the catalytic tower, it introduces catalysts and bauer porcelain to reduce the pour point and liquefy waxy components in the pyrolysis oil. This prevents wax oil deposition and potential blockages. Therefore, this system ensures smoother oil flow and the overall stability system, thus increasing production efficiency by 200%.

Flare System

Excess syngas may cause safety hazards of system overpressure and storage. Emergency incidents such as power outages that may occur during equipment operation. To prevent these potential safety hazards, the flare system can be quickly activated in the event of pressure or power abnormalities. This ensures the safe discharge of syngas and prevents system overpressure.

Guaranteed Packing Material

Beston pyrolysis reactor can adopt British Morgan high-temperature ceramic cotton as insulation material. This material does not contain carcinogens and meets EU standards. Not only that, the material has excellent high temperature tolerance and environmental protection performance, effectively reducing heat loss and ensuring the safety of the operating environment.

Global Waste Management Solution: Beston Group in Action

As an industry-leading pyrolysis reactor manufacturer, Beston Group continues to contribute to the global waste recycling industry. We are constantly committed to the R&D of cutting-edge pyrolysis technology. In addition, Beston Group holds a customer-centric development philosophy. Everything we do is for the long-term success of our customers’ projects. The following are successful pyrolysis projects of global customers for your reference:

Beston Group: Your Ideal Supplier for Pyrolysis Reactor

Pyrolysis reactor represents a significant advancement in waste management technology. It offers a versatile and efficient solution. As a professional manufacturer, Beston Group continues to push the boundaries of pyrolysis technology with innovative solutions. Our equipment is an excellent investment option for your waste recycling project. We welcome you to become our partner. Visit us on LinkedIn for more information about Beston pyrolysis reactor for sale.