In the practice of the plastic circular economy, advanced technologies can only realize their true value if they seamlessly integrate into existing supply chains and address real-world challenges. Pyrolysis technology can convert mixed waste plastics into high-quality pyrolysis oil. But how can the “circular value” of this oil be recognized and accounted for downstream? The Mass Balance approach provides the answer, ensuring every unit of recycled input is accurately reflected in the final product.

1. Challenge: Make Recycled Material Value Visible

One of the greatest advantages of plastic pyrolysis oil is its ability to be “remade” into recycled plastics. However, once it enters large petrochemical facilities, it mixes with fossil feedstock and becomes untraceable. Like a drop of fresh water blending into a river, you cannot identify which drop came from which source. This creates practical challenges downstream:

- Plastic manufacturers cannot prove to customers that their products contain recycled content.

- Brands cannot provide credible claims for eco-friendly packaging made from recycled materials.

Without a reliable system, the environmental value of pyrolysis oil cannot be transmitted, and the circular economy loop cannot form. The Mass Balance approach addresses this common industry need.

2. Solution: Mass Balance Approach

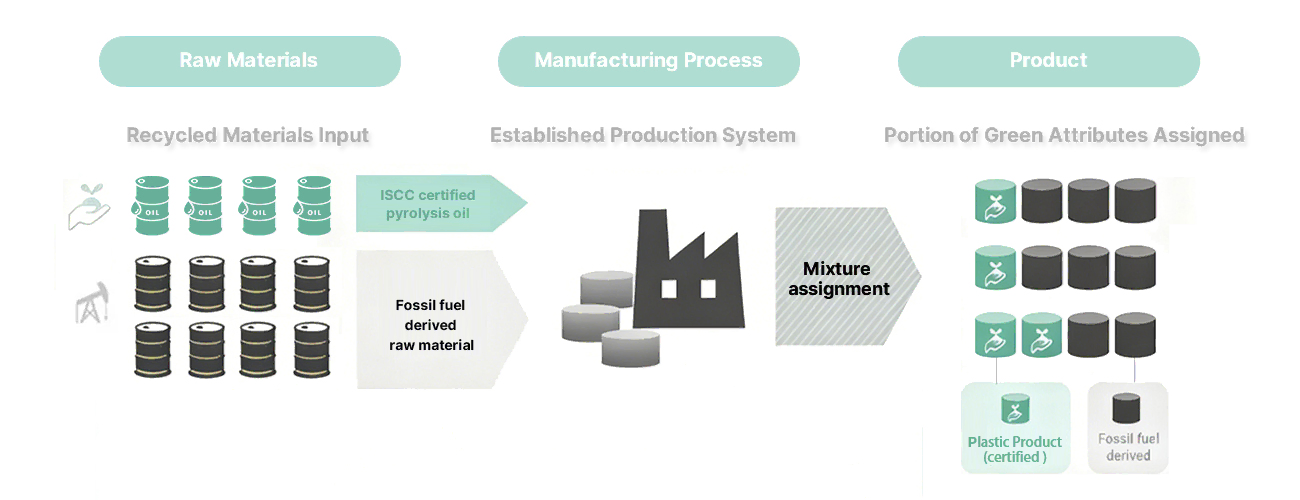

2.1 Definition: Mass balance is the principle of accounting for all the matter in a system, ensuring that the total mass of inputs and outputs is equal, based on the law of conservation of mass. In renewable feedstock supply chains, mass balance does not track individual physical molecules; rather, it accounts for and allocates “green attributes” at each stage of production.

2.2 Status and Recognition: The mass balance approach is widely recognized internationally. Standards such as ISCC PLUS, RSB, and RTRS explicitly use mass balance to quantify and trace green feedstocks. Major brands generally accept mass-balance-certified “green attributes” and use them to make legal and compliant environmental claims on their products.

2.3 Operational Process: Take pyrolysis oil to recycled plastic as an example,

- Input Stage: Certified renewable feedstocks (e.g., ISCC PLUS–certified pyrolysis oil) are co-processed with fossil feedstocks in refining and petrochemical units.

- Accounting System: An independent certification body (e.g., ISCC) audits the entire supply chain to verify the amount of “green attributes” introduced.

- Output Stage: According to predefined rules, “green attributes” are proportionally assigned to output products.

Example: If 100 tons of ISCC PLUS–certified plastic pyrolysis oil are processed within a system producing 300 tons of plastic pellets, the final product may be allocated up to 30% certified recycled content (mass-balance basis). - Allocation and Claims: Downstream plastic product manufacturers can purchase these pellets with “green attributes” and legally make environmental claims on their products.

2.4 Key Clarification: Mass balance differs from physical segregation systems because renewable feedstocks may be co-mingled with fossil inputs; what is certified is the verified accounting of attributes, not the physical separation of material streams.

3. Commercial Benefits of Mass Balance

Why do brands and manufacturers embrace mass balance? Because it delivers real business value:

3.1 Deliver on Brand Commitments & Protect Reputation

Leading FMCG, automotive, and electronics brands have set ambitious targets for recycled material usage, such as 25%–50% by 2025/2030. Mass balance provides the fastest and most reliable way to meet these targets under current technological conditions. It ensures that sustainability claims are credible and legally compliant. Without mass balance, these commitments risk becoming empty promises. By using it, brands protect their reputation, maintain consumer trust, and enhance customer loyalty. This directly contributes to revenue growth and strengthens long-term market positioning.

3.2 Meet Downstream Demand & Seize Market Opportunities

Consumers, investors, and regulators increasingly expect companies to demonstrate environmental responsibility. Using mass balance-certified recycled materials signals a clear commitment to sustainability. It strengthens brand image and differentiates products in the market. This creates opportunities to attract eco-conscious customers, expand market share, and gain competitive advantage. Ultimately, these benefits can translate into higher sales and profit margins.

3.3 Promote Circular Economy & Secure Supply Chains

Brands understand that future competition will extend to supply chains. By supporting and procuring mass balance-certified materials, they invest in a predictable and mature recycled material supply chain. This reduces dependency on virgin materials, mitigates price volatility, and ensures production continuity. Securing sustainable supply chains helps companies lower operational risks and costs. It also future-proofs their business, turning circular economy initiatives into tangible commercial benefits.

4. Illustrative Cases of Mass Balance Application

To make “mass balance” and “recycled content” less abstract, we present three typical illustrative scenarios. (Note: The numbers below are purely illustrative; actual values may vary depending on plant capacity, yields, and certification body requirements.)

Shared Background Assumption (Cases 1–3): A petrochemical plant inputs 500 tons of ISCC-certified plastic pyrolysis oil and other fossil feedstock to produce 5,000 tons of PE/PP resin in a week. The certification body records 500 tons of “green attributes” entered the production system this week.

Case 1: Recycled Content Accounting

Key Points: The recycled content percentage is not arbitrarily set; it is derived through scientific accounting and certification audits.

This entire batch of 5,000 tons PE/PP resin can be sold as certified mass-balance material containing 10% recycled content.

Case 2: Selective Allocation

Key Points: “Green attributes” can be allocated according to customer demand but cannot be arbitrarily increased or reduced.

Scenario 1: Regular Allocation – Based on Purchase Demand

| Customer | Purchase Demand | Allocated Green Attribute |

|---|---|---|

| A | 500 tons of resin containing 30% recycled material | 150 tons |

| B | 2000 tons of resin containing 10% recycled material | 200 tons |

| C | 1000 tons of resin containing no recycled material | 0 tons |

| Other Customers | Allocated as needed | Remaining balance: 150 tons |

Note: The total allocated amount cannot exceed the available “Green attributes”. The entire allocation process is supervised by the certification system to ensure rigor and transparency.

Scenario 2: Special Allocation — Producing “100% Recycled” Products

To produce products labeled “100% Recycled,” a customer purchases 500 tons of resin and is allocated 100% “Green attributes”. The remaining 4500 tons of resin cannot be sold as certified recycled material and must be treated as conventional resin.

Case 3: Supply Chain Transfer of Recycled Material Attributes

Key Points: Mass balance allows the green attribute to transfer across processes and products in the supply chain, enabling compliance, transparency, and traceable business value.

Example: Customer B purchases 2,000 tons of resin containing 10% recycled content, accompanied by an ISCC PoS (Proof of Sustainability). The packaging plant uses this resin to produce 50 million shampoo bottles. The brand can legally label the packaging as: “This product contains 10% chemically recycled plastic from post-consumer recycled sources (ISCC PLUS certified).”

5. Conclusion

Pyrolysis technology solves the raw material challenge of mixed waste plastics, while mass balance ensures that the value of these materials can be recognized and accounted for downstream. For brands, manufacturers, and procurement teams, it is not only an environmental tool but also a pathway to stable supply, brand protection, and market advantage. In today’s global push for a circular economy, those who effectively integrate pyrolysis recycling with mass balance will gain a head start in the next wave of packaging material innovation.