1. Introduction

1.1 Background Overview

With the development of global pyrolysis technology, the pyrolysis and refining technologies for waste tires and plastics have been continuously upgraded. Traditional pyrolysis and distillation processes have problems such as high energy consumption, lengthy process flow, and large equipment footprint. This is why the integrated pyrolysis-distillation technology has emerged. It achieves the goals of energy conservation and consumption reduction, optimizes product distribution, and improves economic benefits by synergistically conducting the pyrolysis reaction and distillation separation process in the same process.

1.2 Research Objectives

This report aims to:

① Clarify the core technical path of integrated pyrolysis and distillation;

② Analyze technological advantages and industrial application cases;

③ Guide enterprises to achieve efficient, green, and intelligent process transformation in the pyrolysis production of waste tires and plastics.

2. Technical Concepts and Principles

2.1 Overview of Pyrolysis Process

The pyrolysis process mainly includes:

- Pyrolysis: Decomposes large-molecule hydrocarbons at high temperatures to produce small-molecule products such as olefins and alkanes.

- Catalytic Pyrolysis: Utilizes catalysts to lower reaction temperature and enhance selectivity, commonly used in the pyrolysis of naphtha and heavy oil.

- Key Parameters: Reaction temperature: 450–750°C (depending on feedstock type); reaction pressure: atmospheric pressure to medium pressure; reaction time: seconds to minutes.

2.2 Overview of Distillation Process

Distillation is a physical process that separates components based on boiling point differences. The conventional distillation column is used for preliminary separation of light and heavy fractions. The rectification column is used for high-purity product separation.

Core technical indicators: Reflux ratio; number of trays or packing height; temperature and pressure layer within the column.

2.3 Integrated Pyrolysis-Distillation Concept

Pyrolysis – Distillation Integration (PDI) refers to directly achieving product separation during the pyrolysis reaction process, reducing intermediate storage and intermediate heating, enhancing product yield through reflux and heat integration, reducing total energy consumption and shortening the production cycle.

3. Analysis of Core Technology Paths

3.1 Technical Route Selection

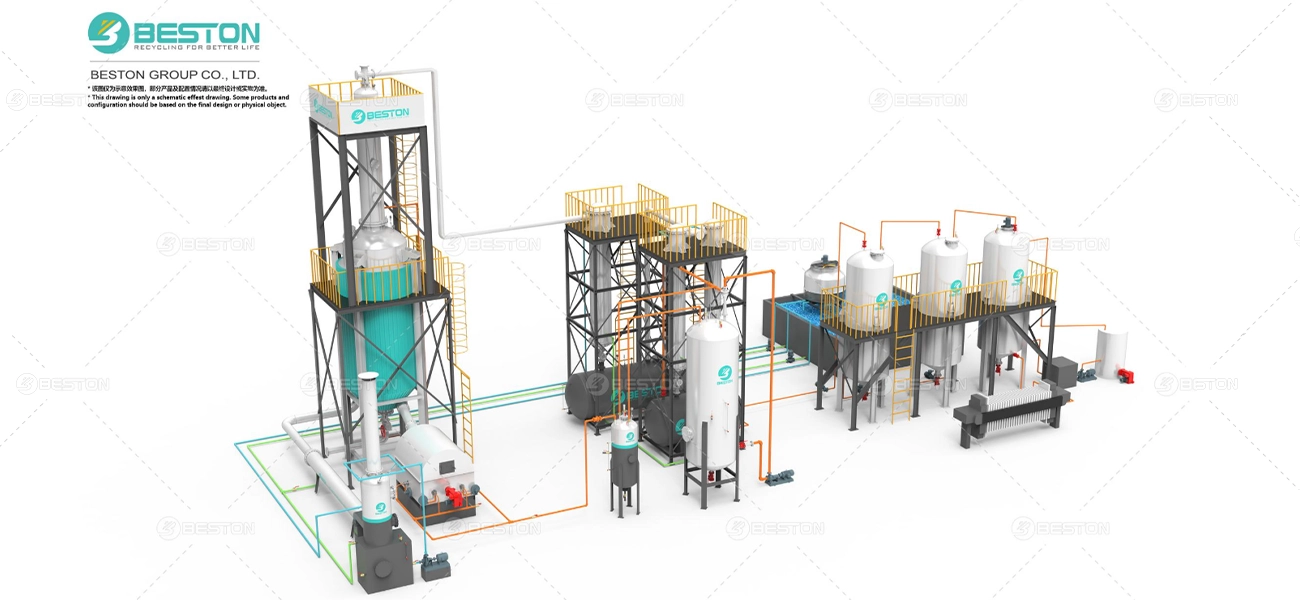

- Direct coupling type: The outlet of the pyrolysis reactor directly enters the distillation column, suitable for feedstocks with high light components.

- Indirect coupling type: Temperature and pressure are adjusted through heat exchange or an intermediate storage tank to achieve product diversion and circulation.

3.2 Key Technological Nodes

- High-temperature pyrolysis reactor design: Tubular or fluidized-bed reactors, high heat-resistant materials, catalyst optimization.

- Integrated column structure optimization: The interior is equipped with a fractionation zone and a reaction zone, where light components rise rapidly and heavy components reflux for further pyrolysis.

- Thermal energy integration and waste heat recovery: Combustible gas is recovered for reaction and distillation heating, and combustible gas can be converted into naphtha through regeneration reaction.

- Product reflux and distribution strategy: Dynamically adjust the reflux flow of light/heavy components to ensure pyrolysis selectivity and distillation purity.

3.3 Control and Optimization Technologies

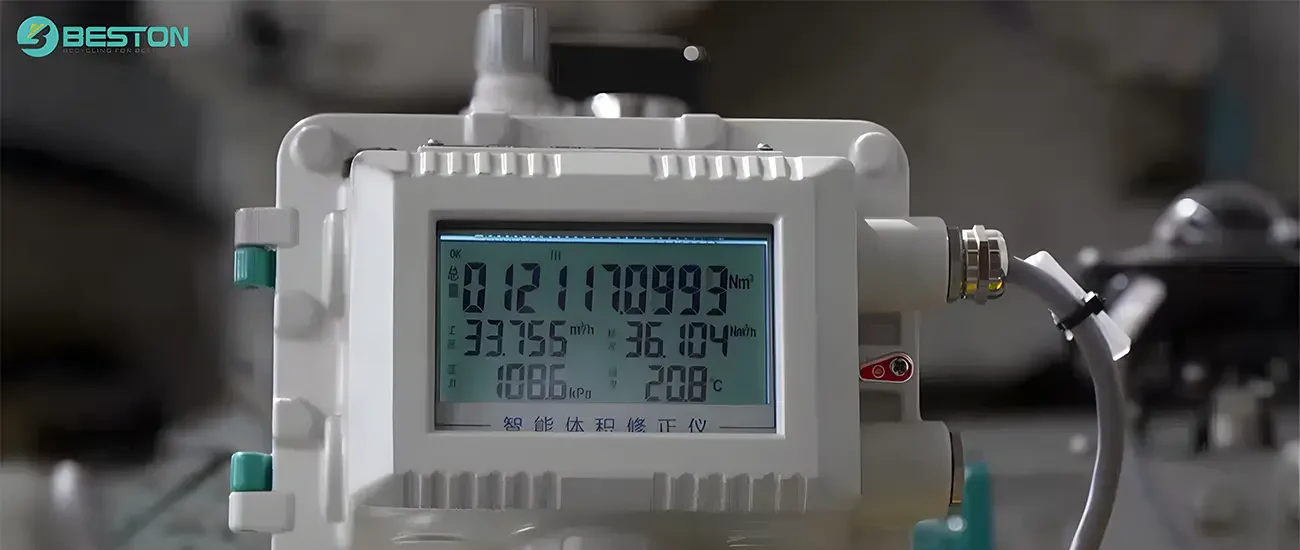

Multi-point temperature and pressure monitoring; Real-time detection of product distribution (online analysis); Online evaluation and update strategy for catalyst activity.

4. Technical Advantages and Challenges

4.1 Advantages

- Energy conservation and consumption reduction: Reducing heating and cooling loads.

- Product optimization: High yield of light components and sufficient recovery of heavy components.

- Investment optimization: Reducing the need for intermediate equipment, lowering occupied space and capital expenditure.

4.2 Challenges

- High-temperature and high-pressure equipment requires high reliability.

- Process control is complex and requires high-precision instruments and intelligent control.

- The catalyst deactivates quickly and needs to be replaced or regenerated regularly.

5. Future Development Trends

- Intelligent control and digital factory: Process simulation and artificial intelligence optimization to achieve real-time optimization of product distribution, energy consumption, and equipment status.

- Application of high-efficiency catalysts & advanced materials: Highly selective pyrolysis catalysts and high heat-resistant, corrosion-resistant column lining materials.

- Green and low-carbon technologies: Waste heat recovery, steam integration. CO₂ emission control and environmentally friendly process pathways.

6. Conclusion

Through process coupling, thermal integration, and intelligent control, the integrated pyrolysis-distillation technology achieves highly efficient and energy-saving production that is towards environmentally friendly development. Through optimization of core technology paths and applying them in practical engineering, it can effectively increase the yield of light olefins, reduce energy consumption, and lay the technological foundation for future intelligent pyrolysis plants.