1. Project Background & Challenge

The client, based in Indonesia, has been engaged in the production and sale of coconut shell charcoal for many years. Previously, the company relied on traditional production methods, which led to inconsistent charcoal quality, low efficiency, and limited output. These are making it difficult to meet the growing demand for shisha charcoal.

2. Goals for Change

To further enhance its market competitiveness, the client aims to achieve the following goals through this project:

- Shift from low-efficiency production to a highly automated manufacturing process;

- Stabilize and improve the quality of the finished charcoal to meet international shisha charcoal standards.

- Upgrade equipment to enable continuous operation and achieve a daily output of 25 tons of high-quality shisha charcoal.

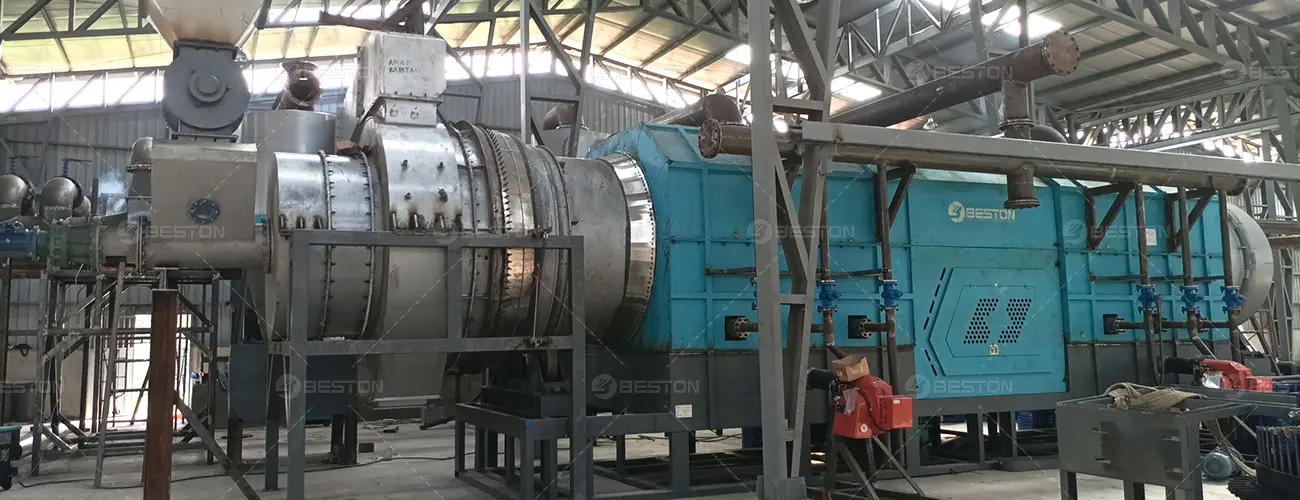

3. Action and Solution

The client ultimately chose Beston Group’s BST-50 biochar production equipment, paired with the coconut shell crusher and dryer, rotary screen, shisha charcoal briquette machine, shisha charcoal dryer, and packaging system. Together, they form a high-efficiency and high-automation production line with the following advantages:

- Stable charcoal quality: The intelligent temperature control system ensures precise carbonization temperature and complete carbonization.

- High automation: The production line can operate continuously for 720 hours, significantly reducing manual labor.

- Large capacity: The BST-50 charcoal machine can process 10–15 m³ coconut shell per hour and run stably for 7,200 hours per year, enabling high charcoal output.

4. Project Outcomes

The project has promoted the high-value utilization of local coconut shell resources, generating significant economic benefits and strengthening the company’s brand reputation.

- Successfully established a highly efficient shisha charcoal production line with a daily capacity of 25 tons.

- Achieved stable production of high-quality shisha charcoal, meeting the growing market demand.